(1) Curtain Coating Features

Curtain coating is suitable for a large number of coatings on flat panels, and has the following advantages:

(1) The coating efficiency is high, and the running speed of the conveyor belt is as high as 50~100m/min;

(2) There is almost no loss of paint, only a small amount of solvent volatilization;

(3) The thickness of the coating film is uniform, the film thickness error can be controlled within 1~2µm, and it has a good appearance;

(4) Simple operation, good workability and sanitation, as long as the parameters of the equipment are well adjusted, the production process will be very stable;

(5) It can also be applied to two-component coatings and quick-drying coatings. Two-component coatings need to be equipped with two coating curtains, and quick-drying coatings are conducive to shortening the length of drying equipment.

The defects of curtain coating have the following aspects:

(1) It is not suitable for multi-variety and small-batch operations, because a large amount of solvent is required to continuously clean the paint circulation system when the paint is frequently replaced, which is time-consuming and uneconomical;

(2) Not suitable for vertical surface coating;

(3) It can only be thickly coated and not thinly coated, because to form a continuous curtain, the coating needs a higher viscosity, and the film thickness obtained in this way is generally above 30µm;

(4) Paper, fabric and leather need to be stretched on the hard board to be curtain coated.

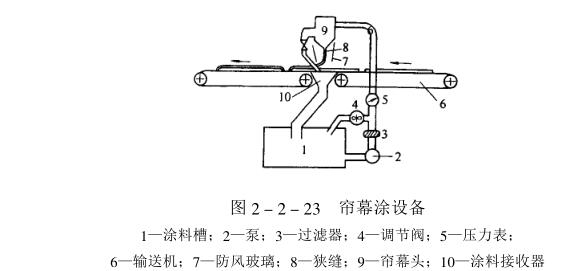

(2) Curtain coating equipment

The painting equipment consists of four parts: paint disinfection, paint circulation device, paint curtain head and belt conveyor, see Figure 2_2_23. The heat exchange medium in the central sleeve is used for paint disinfection to keep the temperature of the paint constant, and the volume is generally 40~50L. The paint circulation device is equipped with an overflow regulating valve to keep the paint pressure in the curtain head constant. The curtain head consists of Saijo's high-precision blade-shaped sharp edges, which are fixed on one side and adjustable on the other to create a slit. Windshields are used to prevent airflow from disturbing the curtain.

(three) curtain coating process parameters

The main process parameters affecting curtain coating are paint viscosity, paint pressure, slit width and conveyor speed, among which the slit width has a particularly large impact on curtain stability and coating amount.

1. Paint viscosity

The viscosity of the paint has a great influence on the stability of the curtain. When the paint is thin, the curtain is easy to break. Generally within the viscosity range of 30~150s, it can ensure a stable curtain for various coatings.

The viscosity of the paint should also be determined according to the type of paint, the material to be coated and the thickness of the paint film. For example, the viscosity of stone Xiaoji paint and general paint is 25~30s, the viscosity of polyester high solid content paint is 30~50s, the metal surface should be coated with 30~50s paint; but the porous wood surface should be coated with 70~100s paint, keep a good decorative appearance,

2. Slit width

The adjustable range of the slit is 0.3~1.2mm. When the paint pressure is constant, as the slit becomes wider, the curtain descending speed will slow down. Open; when the slit is too wide, the curtain falling speed is not suitable for the speed of the fast conveyor, resulting in uneven coating. The suitable range of the slit is generally 0.5~0.8mm, and the width of the slit is adjusted according to the viscosity of the paint. If there is an appropriate amount of outflow,

3. Paint pressure

The paint pressure has a great influence on the outflow speed, that is, the coating amount. The paint pressure in the curtain head is generally controlled at 10~20kPa.

4. Conveyor speed

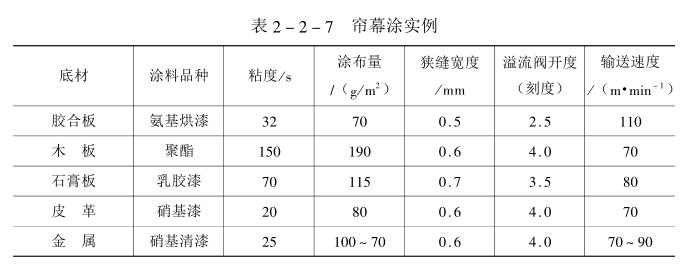

When other parameters are determined, the conveyor speed can also be adjusted to change the coating amount. Although the conveyor is steplessly adjustable within 0~150m/min, the coating film is discontinuous if it is too fast, and the coating film is too slow if it is too slow. Generally, it is adjusted within 70~90m/min, and the corresponding coating amount is 100~70g/m2. In short, the curtain coating process parameters are adjusted according to the following procedures: Select the coating type according to the coating quality requirements. Determine the viscosity of the coating according to the thickness and material of the coating - determine the width of the slit - properly increase the pressure of the coating to ensure that the curtain does not break - adjust the speed of the conveyor so that there is an appropriate amount of coating, the curtain coating example is shown in Table 2-2-7 .

In addition, curtain coating needs to be equipped with drying equipment, and is especially suitable for quick-drying coatings, which can greatly shorten the length of the conveyor chain. For example, the forced drying of nitro paint takes 3 minutes, and the conveyor chain passes through the conversion device to reduce the drying chain speed, and the drying equipment can be greatly shortened.