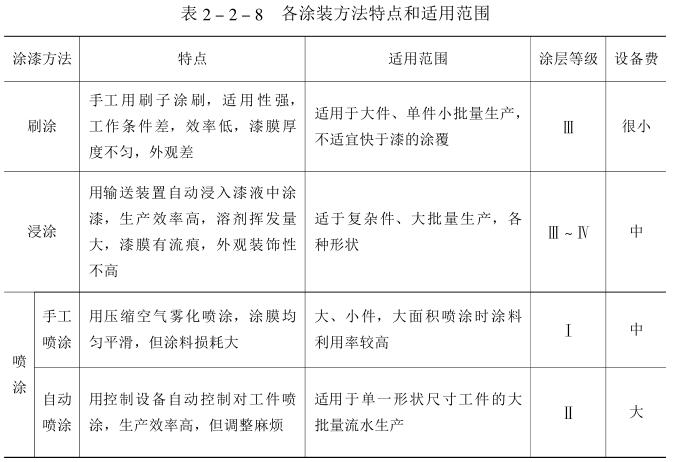

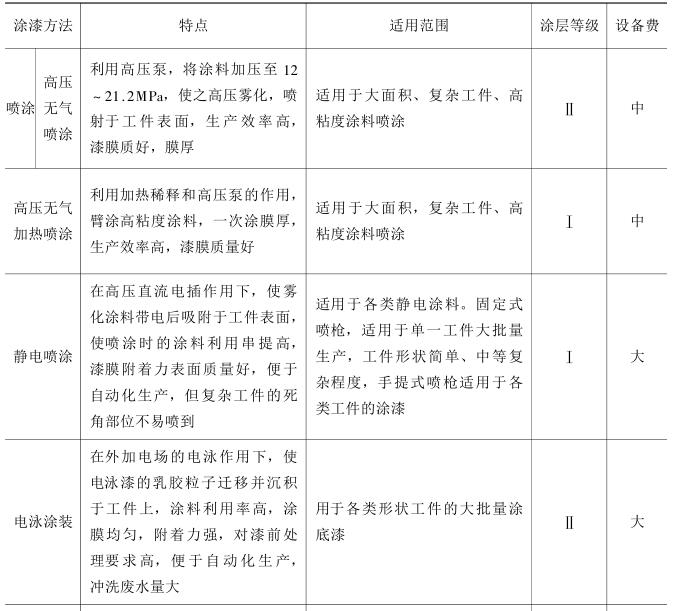

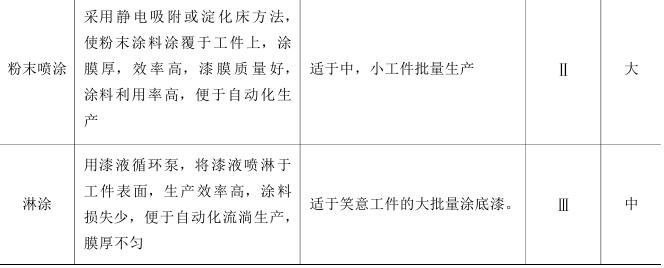

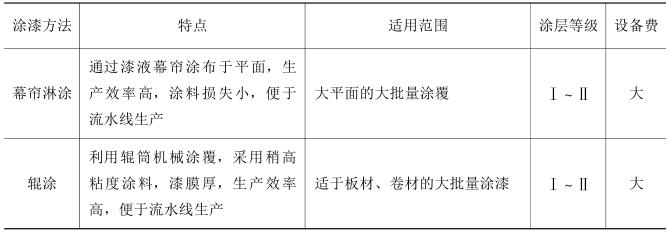

There are many coating methods, and different coating methods have different characteristics, which are suitable for different batches, different workpiece shapes and different coating requirements. The characteristics and scope of application of commonly used coating methods are shown in Table 2-2-8.

Note: Coating Appearance Grade L—the coating film has no defects, is smooth and flat, and has no particles; ll—the coating film has good flatness, or there are a few inconspicuous particles; lll—the coating film has a few obvious particles, or the thickness is not good Uniform, almost flatness; lv one has obvious defects, such as flow marks, poor flatness, uneven color, etc.

The following aspects need to be considered when choosing a coating method:

(1) The material, specification, size and shape of the workpiece,

(2) The environmental conditions of the object to be coated;

(3) The physical properties and construction performance of the coating;

(4) Coating quality and standards;

(5) Coating production organization and scale;

(6) Coating environment and economic benefits, etc.

Considering the material of the workpiece, there are mainly metal, plastic and wood. For electrophoretic painting, it is only suitable for metals, and different metals cannot be painted by electrophoretic painting at the same time, and this method of painting cannot be used for plastics and wood. For electrostatic spraying, a certain degree of electrical conductivity is required on the surface, so plastics and wood need to be specially treated before this painting method can be used.

From the shape of the workpiece, for workpieces with complex shapes such as gaps and corners, air spraying and electrostatic spraying should not be used. High-pressure spraying or electrophoretic coating can be used, while curtain coating or roller coating can be used for flat objects.

Considering the size of the workpiece, electrostatic spraying should be used for mass production of small pieces. If air spraying is used, the paint utilization rate is very low.

From the perspective of operating environment, production efficiency, coating quality and coating utilization, electrophoretic coating has great advantages. However, cathodic electrophoresis equipment requires a large investment and strict management requirements. First of all, it should be checked whether its renewal period can meet the requirements. Others such as powder spraying and high-pressure spraying are also environmentally friendly operations with high production efficiency, and a coating film can reach 100µm. However, to obtain decorative coatings, air spraying, electrostatic spraying or heating spraying are usually used.

In addition, the coating method has been continuously improved in terms of coating quality, environmental protection, safety and production efficiency. Therefore, it is necessary to use professional coating methods and techniques as much as possible.