Factors Affecting Film Thickness

(1) Powder supply

When the water pipe is used for suction coating, the thickness of the coating film increases with the increase of powder supply, but it is not obvious. Since the powder coating is excessive during vacuum suction coating, the size has little effect on its thickness.

(2) Preheating temperature

Because the vacuum suction coating belongs to the preheating coating category, the powder is mixed with air and enters the pipe, and it melts and adheres to the surface of the pipe wall when it contacts the high-temperature pipe wall. During the suction process, the air flow takes away part of the heat from the tube wall to lower the temperature, and the amount of powder adhered will also be reduced, or even not adhered. Therefore, the level of pipeline preheating temperature has a great influence on the change of coating film thickness.

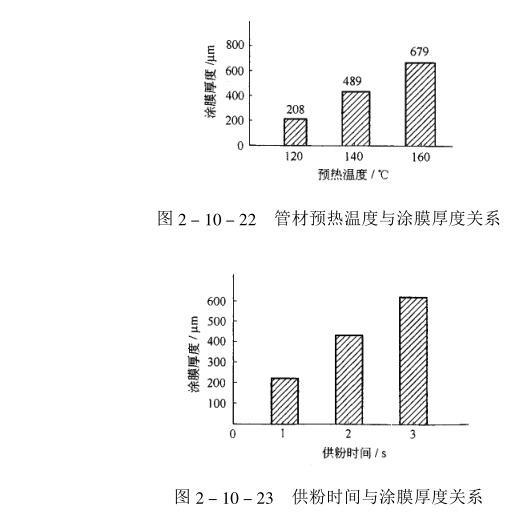

The test results obtained by suction coating of epoxy powder coating on DN15mm pipe are shown in Figure 2_10_22. There is a linear relationship between preheating temperature and film thickness.

(3) Powder supply time

The thickness of the coating film is very sensitive to the powder supply time. Under the same conditions, the longer the powder supply time, the thicker the coating film, as shown in Figure 2_10_23; during the suction coating construction process, the temperature of the pipeline is continuously reduced due to heat dissipation, heat absorption by the powder, and heat taken away by the suction airflow. When the temperature of the tube wall drops to the point where it is difficult to fuse the powder, the thickness of the coating film cannot be increased no matter how long the powder supply time is.

In the production and construction, with the change of pipe diameter, batch size and production cycle speed and other factors, the relevant process parameters should be adjusted accordingly to obtain a satisfactory coating film.