(1) Washing

The purpose of water washing is to remove the floating paint adhered to the surface of the coating film due to immersion of the workpiece during the electrophoretic coating process, so as to prevent the coating film from being stained, and at the same time prevent the adhered floating paint from re-dissolving the coating film.

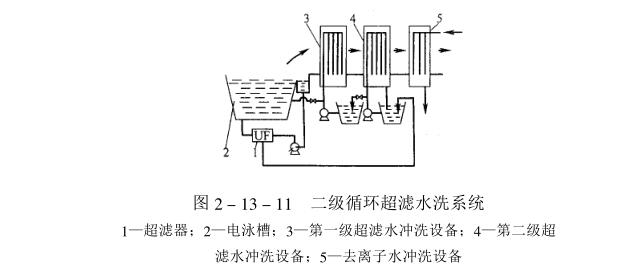

Water washing includes ultrafiltration water washing and deionized water washing. At present, the ultrafiltration washing process mainly adopts two-stage circulating ultrafiltration washing or one-stage ultrafiltration washing. The former is suitable for large-scale assembly line production, and the latter is usually used for small-batch intermittent production. The two-stage circulating ultrafiltration water washing system is shown in Figure 2_13_11.

Some nozzles are also installed above the overflow tank, and before the workpiece leaves the electrophoresis tank, most of the floating paint is washed back into the tank, which greatly reduces the burden of other washing processes.

Because the ultrafiltration water contains, solvents, small molecule additives and inorganic salt ions, it is necessary to wash the ultrafiltration water on the surface of the coating with deionized water. Generally, a cycle of decontaminated water is used for washing, and a pure decontaminated water is used for washing. Adding 0.5%~3% surfactant is good for improving the appearance of the coating film, increasing the smoothness, and overcoming water marks.

(2) drying

The curing condition of the electrophoretic primer is generally 160~180℃/30min. Infrared radiation and convection are widely used in production. Since the electrophoretic coating uses water as a solvent, the evaporation of water is very high, the density is high, and the water vapor is not easy to get rid of. , the coating film is easy to dissolve and lose light in the hot water vapor, so it is difficult to ensure the quality only by radiant heating. A certain proportion of hot air is discharged in time through convection to ensure the humidity of the hot air in the drying room, which is conducive to ensuring the quality of the coating. .

(3) Inspection

In addition to inspecting the appearance of the coating film, such as whether it is flat, smooth, and dense, the thickness of the coating film (generally 20~35µm), corrosion resistance, adhesion and impact resistance should also be inspected.