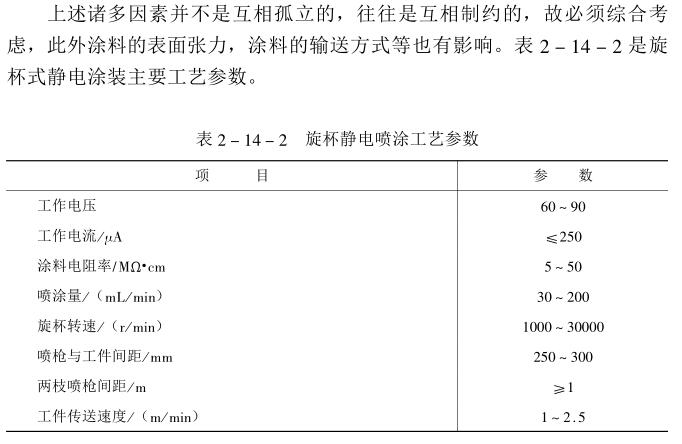

静电涂装的质量与许多工艺参数有关,以旋杯式静电涂装为例,有下述主要因素:

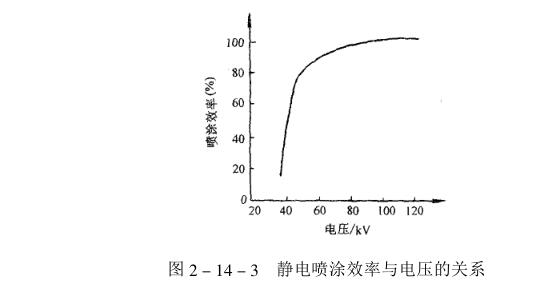

一、静电高圧

电压是静电涂装十分重要的参数,图2_14_3表示电压与喷涂敛率的关系,当电压低于40kv时,喷涂效率仅20%左右,此后喷涂效率随电压的升高迅速增加,在60kv时,可达80%以上,电压再升高,变化趋于饱和,即喷涂效率无明显增加。虽然采用高电压,有利于涂料带电荷,提高喷涂效率,但随之而来的问题是对整个喷涂系统的绝缘性要求提高,并易发生高压击穿导致火灾的危险,所以除某些品种涂料需要要高电压外,一般电压范国可控制在90kv左右。近年来新开发的静电喷涂装置一般都设置有防击穿安全保护系统,已使高电压安全性得以保障。

二、旋杯的转速

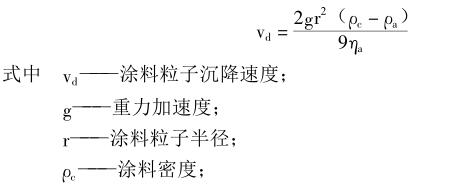

在旋杯式静电喷涂涂装系统中,涂料的初级雾化主要依靠旋杯高速旋转离心力的作用,进而在高压静电场的作用下,涂料粒子进一步静电雾化,并在电场作用下,喷涂于工件表面,与此同时涂料粒子在重力作用下发生沉降,雾化的涂料粒子在电场中的沉降速度为:

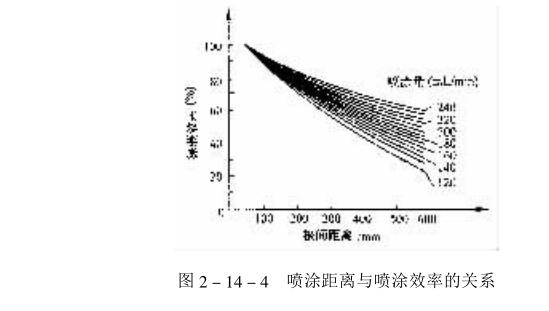

三、喷枪与工件的距离

一般每1cm间隔空气能承裁10kv电场作用,如果电场强度为的90kV则理论极间距富至少为9m,低子出极限値就会有极间击穿,产生火灾的危险,实际使用时,需要取3倍的安全系数,嘘除效章与极间距富的关系见图2-14-4.

从图2-14-4可以看出,喷涂距离愈近,喷涂效率愈高,结合安全性及质量因素考虑,一般在90KV电场强度下,喷涂距离以30~35cm为宜,距离过远会显著降低喷涂效率。

四、涂料的粘度

一般涂料粘度愈高,雾化性能愈差,对喷涂效率产生不利影响,国内一般控制在15~20s(涂_4杯),但从质量因素考虑,粘度应尽可能高些,这样可以增加涂料的固体分,使涂层有较好的光泽和丰满度,为此采用提高喷涂温度的措施是一有效的途径,国外生产线采用30~40℃甚至更高的恒温喷房,喷涂底漆粘度为25~30s,面漆粘度为30~40s,可满足高固分涂料的静电涂装。

五、涂料的电性能

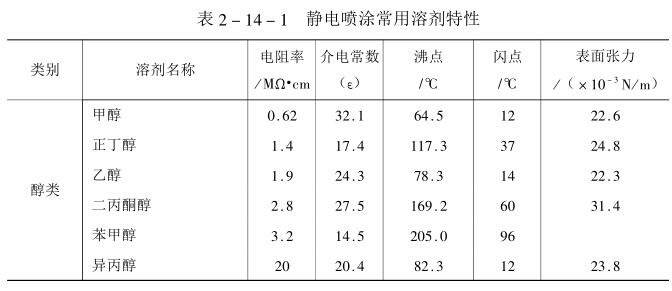

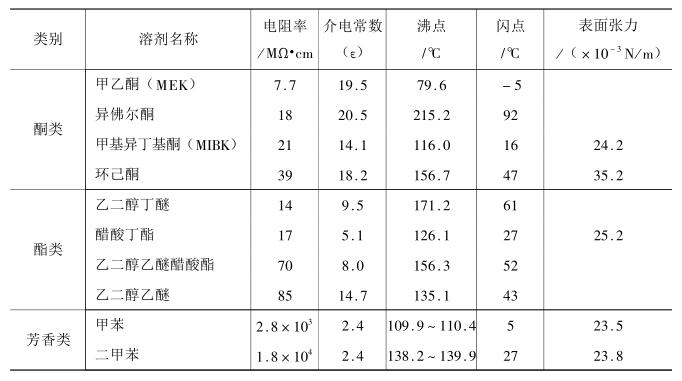

According to the principle of electrostatic painting, the ability of paint particles to charge in an electric field must be related to the electrical properties of the paint, and the most important parameter is the dielectric constant of the paint. Generally, the polarity of ordinary paint is very low, and its impedance is often greater than 100Ma. In order to make the paint adapt to electrostatic coating, it is necessary to use a solvent with a high dielectric constant or a special electrostatic thinner to adjust the impedance of the paint to 5~50Ma. In between, while adjusting the impedance, it is also necessary to take into account the leveling of the coating, that is, to use some high-boiling solvents to control the proper volatilization speed of the solvent, achieve better leveling, and improve the decorative properties of the coating. . The characteristics of commonly used solvents for electrostatic coating are shown in Table 2_14_1.

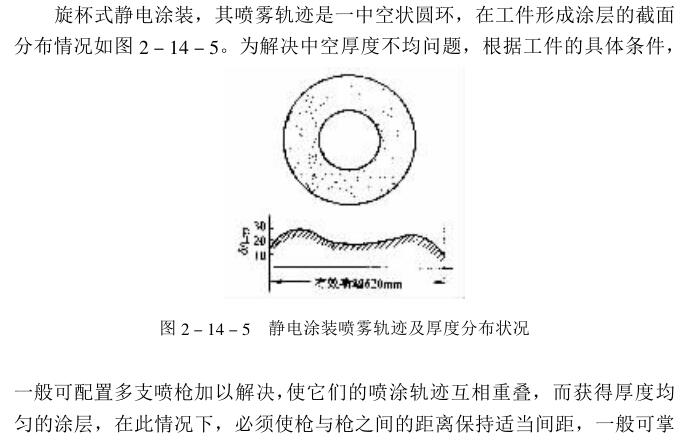

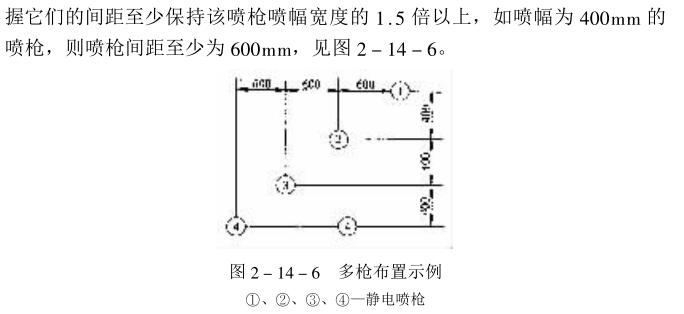

6. Arrangement of the Spray Gun

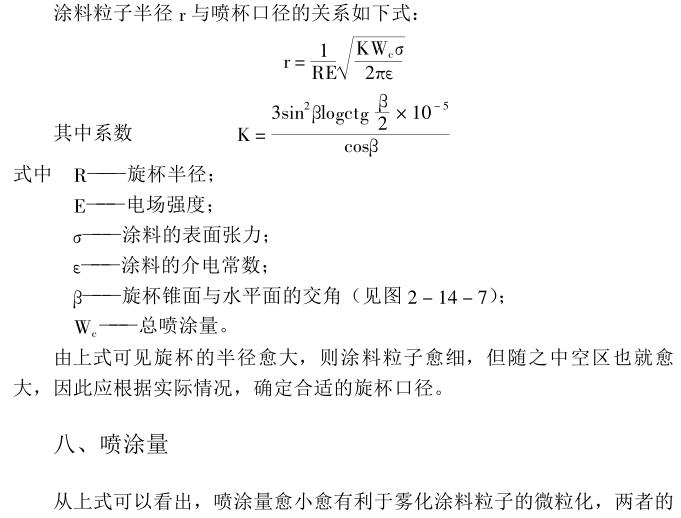

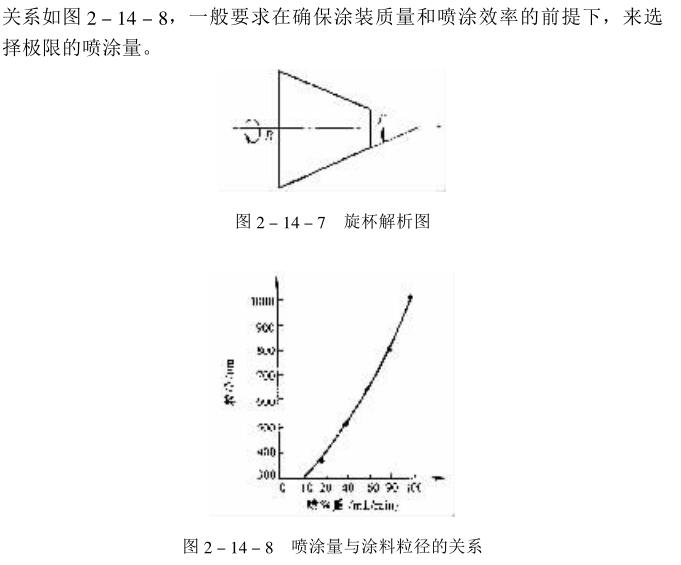

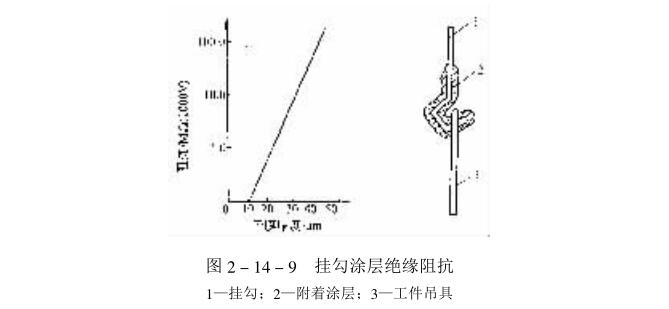

Seven, the caliber of the spray cup