This test method actually stipulates how to make a standard paint test panel for the test. For details, see GB1727-92. This standard specifies the materials for preparing general paint films, the surface treatment of base plates, the method of making plates, the drying and state adjustment of paint films, constant temperature and humidity conditions, and the thickness of paint films, etc. It is applicable to the preparation of test plates for general performance.

Model bottom plates include: tin plate, glass plate, steel plate, aluminum plate, asbestos cement plate, etc. The commonly used ones are as follows.

(1) The tinplate should first be polished with No. 500 water sandpaper to remove the tin coating. The grinding method is: grind back and forth flatly and evenly along the parallel direction of any side of the test plate; then grind flatly and evenly in the direction perpendicular to the first direction until the original surface tin layer is worn away; then use a diameter of about 80~100mm Grind in a circular motion until the circles formed on the surface overlap. Wipe off the floating dust with absolute ethanol, and let it dry for later use.

(2) Wash the glass plate with hot soapy water, rinse it with clean water and wipe it dry, then wipe it with solvent, and dry it for later use.

(3) Wipe the hard aluminum plate with absorbent cotton dipped in solvent before use, and dry it for later use.

(4) The surface of the board can be polished with No. 1 alumina emery cloth, and wipe off the dirt for later use.

(5) The tinplate plate used in the heat resistance test needs to be baked at 400~500°C for half an hour before polishing to oxidize the tin coating, take it out, and polish it according to (1) method after cooling.

(6) The asbestos cement board is polished with emery cloth to remove oil and floating dust, soaked in water for several hours until the pH value is close to 10, and then dried for later use.

Different plate making methods can be used, such as painting, spraying, dipping, scraping, pouring and so on. First of all, the paint sample should be diluted to a suitable viscosity. When brushing, use a paint brush to dip the paint, not too much, and quickly and evenly paint the vertical and horizontal directions on the specified bottom plate to form a uniform paint film. Blank or overflow phenomenon. When spraying, the distance between the Spray Gun and the surface to be coated should not be less than 200mm, the spraying direction should form an appropriate angle with the surface to be coated, the air pressure should be 0.2~0.4MPa, and the moving speed of the Spray Gun should be uniform.

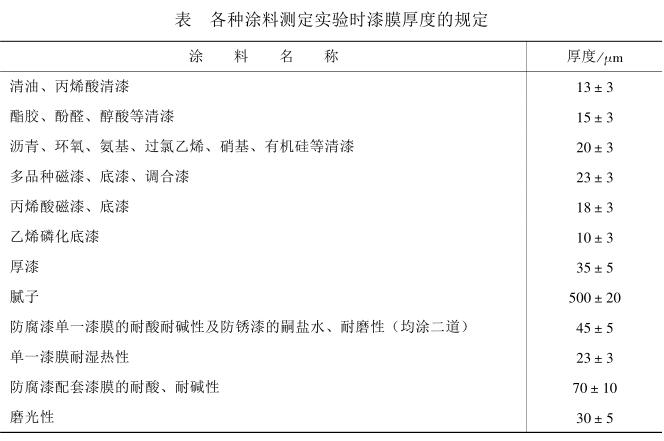

The coating sample prepared according to the standard needs to carry out a series of inspections on the performance of the coating film, such as measuring adhesion, flexibility, impact strength, etc. Therefore, the dry film thickness of the formed coating film should not be too thick, between 15 and 30 µm Otherwise, it will affect the test performance of other projects. The following table lists the film thickness specifications after drying of various paint films. Unless otherwise specified, the paint film should be prepared according to the following film thickness as far as possible.