In coating engineering, coating film thickness is one of the important means to control coating quality. The method of measuring dry film thickness to ensure engineering coating quality is called film thickness management. For example, the thickness of the coating film is an important factor affecting its anti-corrosion performance, and the coating film used for industrial anti-corrosion generally requires a dry film thickness between 200 and 350 μm.

Reasonably control the appropriate thickness, which is related to various factors in the coating process, such as construction method, non-volatile matter during construction, surface treatment and adsorption capacity of the substrate, and volatilization rate of the thinner. For the specific content of film thickness management, please refer to the relevant content in Chapter 4, Section 4.

For the control of coating film thickness, Western methods are generally used.

(1) Determination of wet film thickness during construction

In order to effectively control the coating film thickness, it is necessary to measure the wet film thickness during the coating process. Each wet film needs to reach a certain thickness. After drying to form a film, a dry film that meets the requirements can be obtained. The thickness of the wet film and the thickness of the dry film have the following approximate relationship:

Dry film thickness (µm) = wet film thickness (µm) x solid content (%) of the coating.

Therefore, the determination of wet film is very important to ensure the quality and quantity of coating work. The measurement of the wet film thickness needs to be carried out immediately after painting to avoid shrinkage of the paint film due to the volatilization of the solvent. The commonly used instruments and methods for measuring wet film thickness are mainly western ones.

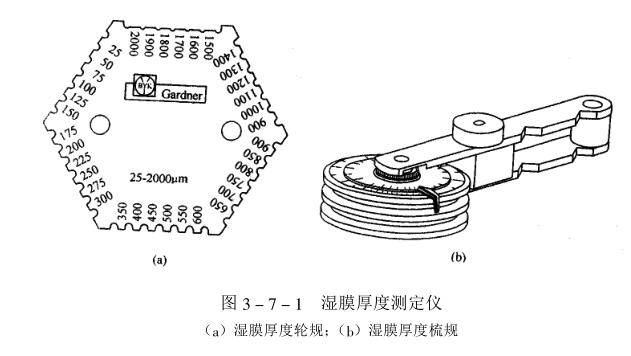

(1) Wet film thickness wheel gauge [Figure 3_7_1(a)]: The wheel gauge is composed of three rings, the outer west circle is concentric and has the same diameter. The middle ring and the outer ring are usually eccentric by 75µm and have a diameter of 150µm, so the highest points of the three rings are on the same straight line, which is used as the ring of the zero line, and a height difference is formed at the lowest point, which is the maximum value of the instrument. range. Different instrument models have different measuring ranges.

When using, pinch the guide wheel with your thumb and middle finger, let the maximum scale value of the ring touch the wet film, then roll to zero, observe the scale value where the wet film first contacts the middle ring, this is the measured value The obtained wet film thickness, the wheel gauge wet Film Thickness Gauge can also be installed on the handle, many of this handle is used to safely measure the thickness of the moving surface such as high-speed roller coating, it can also be used to facilitate the fixed object , flat or curved surface, because this handle can make it easier for the operator to press the force stably on the instrument,

(2) Wet film thickness flow gauge [Figure 3_7_1(b)]: The flow gauge is usually made of aluminum or stainless steel plate, the number of teeth is the number of scale lines of the gauge, and the height between the teeth and the reference line at both ends Different scale values are available, flow gauges with different ranges are available, some are rectangular block Thickness Gauges with different ranges, and some are designed as ruler-shaped hexagons, with base points at both ends of the six faces, each face There are teeth with different lengths, and the range ranges from 25 to 2000 μm. When measuring, press the surface whose range is close to the estimated thickness of the paint film vertically into the wet film until the two ends of the Thickness Gauge are closely connected with the substrate. In this way, some teeth will be soaked by the paint, and the thickness of the wet film is indicated by the reading between the last wet tooth and the adjacent tooth that is not soaked. Using a flow gauge wet Film Thickness Gauge, the surface of the substrate is required to be It is quite smooth and flat, otherwise the inaccurate readings will be caused by surface defects. The wet Film Thickness Gauge should read immediately after the measurement, especially for coatings whose solvents evaporate quickly. Use a metal wet Film Thickness Gauge. Finally, it should be cleaned with a wiping material soaked in the corresponding solvent. Be careful not to rub the tooth edge of the flow gauge or wheel gauge hard. If the wet film thickness does not meet the requirements, it should be repainted or partially repaired and recoated.

(2) Determination of dry film thickness after coating

After the coating film is completely dry, the dry film thickness can be measured according to the national standard GB1764-89 (79). The value of the dry film thickness is an important content of film thickness management. The total film thickness requirements, the national standard stipulates two methods of measuring lever micrometer and magnetic Thickness Gauge, with the improvement of paint detection level, the magnetic Thickness Gauge method is generally used, and the sensitivity of the paint Film Thickness Gauge, The accuracy, applicability and convenience of use are getting higher and higher. Different types of Thickness Gauges have appeared, including digital display, portable and pen-type, lightweight, high sensitivity, and easy to use. Using new instruments, they can measure The film thickness of all coatings on iron and steel substrates can also measure the film thickness of non-magnetic, insulating coatings on substrates such as aluminum, steel, zinc and stainless steel. (aluminum, copper, etc.) use the eddy current method, there are many models at home and abroad, the measurement range is generally 0~600μm, the highest can reach 1.5mm.

The operation method is as follows: put the probe on the sample plate to make it fully absorb with the paint film to be tested, and as the pointer (digital knob) measures the continuous change of the film thickness value, when the magnetic core jumps away, the gauge needle (digital knob) ) when the number is stable, the paint film thickness can be read, expressed in microns (µm). The dry Film Thickness Gauge should be calibrated before and after daily use, and the accuracy of the instrument must be maintained during use. When any abnormality is found, it can be calibrated at any time. When calibrating, place the probe directly on the same treated substrate, and turn the corresponding knob to the "0" position to calibrate the 0 point; place the standard film thickness calibration sheet attached to the instrument on the substrate, and adjust the corresponding Turn the knob so that the reading of the needle (scale) is equal to the thickness of the standard diaphragm; repeat this procedure until it is adjusted to the "0" position and the appropriate thickness. The calibration and measurement of foreign precision dry film thickness measuring instruments are very simple, just press the probe on the coating film to be tested, and wait for the digital to stabilize the reading. At the construction site, a pen-type Thickness Gauge can be used, and the pen-tip probe is adsorbed on the object to be measured. When the thickness value is reached, the probe jumps away from the coating surface and the reading is sufficient. However, this measurement is not accurate, and the error is within 10µm. above.

The measurement of dry film thickness requires that the coating film must be hard and dry. When the probe is pressed to leave marks on the surface of the paint film, it means that the coating is dry and not hard enough. At this time, the test must introduce errors.

When inspecting various physical performance indicators of the coating or counting the total thickness of the paint film after the entire construction, the measured film shall prevail. If the total dry film is less than the specified thickness, the corresponding anti-corrosion protection function cannot be achieved, so it is necessary to reapply 1~2 coats of paint as appropriate.

However, it should not be applied too thickly because of the blind pursuit of high film thickness, which will easily cause sagging, wrinkling, orange peel and other disadvantages. Reasonable construction should be carried out, and regular inspections should be carried out to ensure the quality of the project.