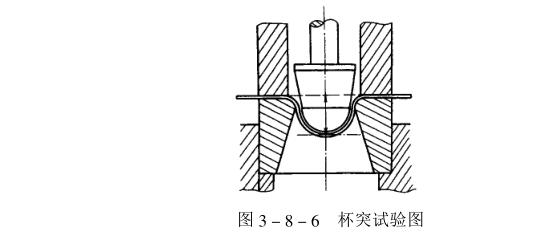

Cupping test (GB/T9753-88)

The cupping test is to detect the ability of the coating to resist deformation and cracking, and it is a comprehensive reflection of the plasticity of the coating film and the bonding force of the substrate. QBJ type coating cupping testing machine is designed and manufactured according to the requirements of IS01520 and GB9753-88. The pressure head is a 20mm steel hemisphere, and the pressure head is moved at a speed of (0.2±0.1) mm/s until the coating cracks. Read Take the corresponding pressure depression depth (mm) as the cupping test value (see Figure 3_8_6).

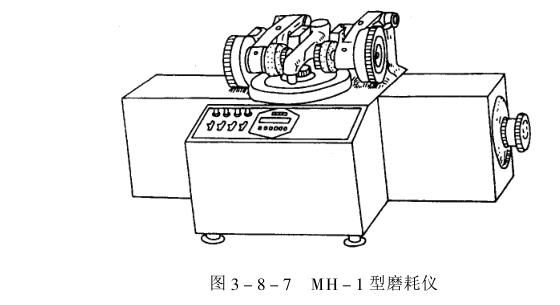

wear resistance

The wear resistance test tests the mechanical wear resistance of the coating film, which is a comprehensive reflection of the cohesive energy of the coating film and the hardness of the coating film. The falling sand method and sandblasting method are used to simulate the natural wear of the coating film at the production site. Rubber grinding wheels are often used in laboratories, and a certain load is applied, which is expressed by the number of wear-throughs or the weight loss at a specified number of revolutions. Such instruments are collectively referred to as Taber Abrasion Tester, and the domestic MH_1 Abrasion Tester is shown in Figure 3_8_7.

Stone chip resistance

The stone impact test is a test method that imitates the impact of sand and stones on the automobile coating during driving. It is used to show the ability of the coating film to resist the impact of high-speed sand and stones. It is a special test technology developed for the requirements of automobile coatings. During the test, spray the steel grit with a particle size of 4~5mm on the sample to be tested with compressed air, spray 500g of steel grit each time, and spray it on the sample with a pressure of 2MPa within (10±1)s, repeat twice, and then paste Pull off the loose coating film with adhesive tape, compare the damage with the standard picture, 0 is better, 10 is the worst. The difference between it and the spray method for measuring wear resistance is that the sand grain size is large and the spray pressure is high, while the wear resistance is expressed by the amount of abrasive required per unit thickness of wear, and the test day is completely different.

The stone impact resistance test method of ASTMD3170-87 stipulates that 9.6~16mm stones are used, the amount of each use is 550ml, and the air pressure is 480kPa±20kPa.

water resistance

According to the provisions of GB/T1733-93, the bottom plate is 120mmx25mmx(0.2~0.3)mm tinplate plate, after the coating film is edge-sealed, immerse 2/3 of the test plate in 23℃±2℃ water (or boiling water), after the specified time Take it out, check and record whether there are any phenomena such as loss of gloss, discoloration, blistering, wrinkling, shedding and rust, and the recovery time.

Gasoline resistance

According to GB/T1734-93, the bottom plate is 120mmx50mmx(0.2~0.3)mm tinplate plate, 2/3 of the test plate is immersed in 120# solvent gasoline at 23℃±2℃, take it out after the specified time, check whether there is any record Wrinkling, blistering, peeling, softening, discoloration, loss of gloss, etc.

chemical resistance

According to the provisions of GB/T1763-89, the bottom plate is 120mmx50mmx (0.45~0.55)mm thin steel plate, LY12 aluminum plate with a thickness of 1~2mm, and; 10~12mm, 120mm long bottom carbon steel rod with a spherical end. Edge banding, steel bar dip coating method, and do soaking test directly after drying,

(1) Salt water resistance: immerse 2/3 of the test panel in 3% Nacl aqueous solution at a temperature of 25°C±1°C, take it out after the specified time, and check for discoloration, loss of light, blistering, peeling, and rust.

(2) Acid and alkali resistance: immerse 2/3 of the painted steel bar in the acid and alkali solution of the specified concentration at a temperature of 25°C±1°C, take it out for inspection every 24 hours, and wash it with tap water for each inspection. Blot the filter paper dry, and observe whether there is discoloration, loss of light, vesicles, spots, or shedding.

Scrub resistance

This is an important performance of architectural coatings. Other coating films are also applicable if they have this requirement. The test uses a QFS type paint washability Tester. The test panel is a 430mmx150mmx3mm glass plate. After cleaning, first coat an iron red alkyd primer. After drying, apply the white latex paint to be tested (if the paint to be tested is a dark paint, the primer should be painted with white alkyd matt enamel paint), so that the dry film thickness of the latex paint is 45 µm ± 5 µm. The test panel is fixed in the test tank of the instrument, and the industrial brush soaked in 0.5% soapy water is placed on the coating film for reciprocating scrubbing, and at the same time, 0.5% soapy water is continuously added until the bottom of the 100mm long area in the middle of the test panel appears. Record the scrubbing The number of times, as a wash-resistant effect.