1. Leveling principle (coating leveling equation)

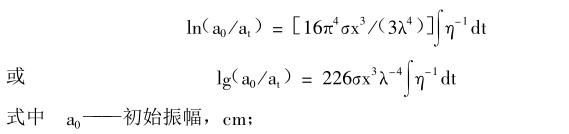

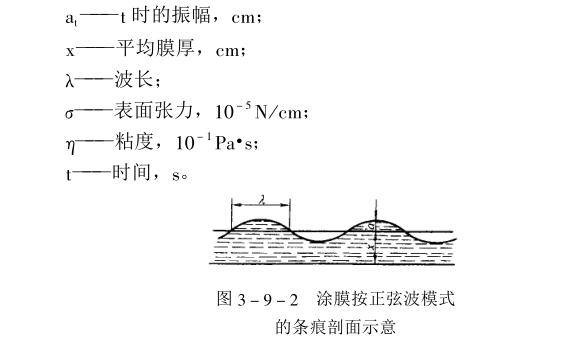

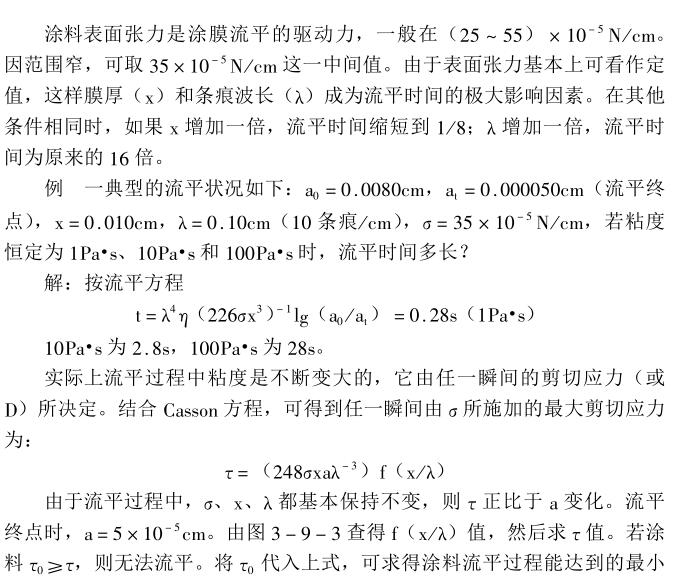

The paint leveling equation can more accurately reflect the experimental results based on the formula derived from the sine wave profile theory (Fig. 3_9_2). Right now:

The leveling equation above is not suitable for angular variants. The recovery of γ1 after shearing by angular variants is time-bound. In addition, during the leveling process, solvent volatilization also causes a continuous increase in viscosity. When painting on porous surfaces, the solvent is absorbed in the pores by capillary action, which will lead to the sudden termination of leveling. For latex paint, in the initial stage of moisture volatilization, the latex particles will transform into a semi-rigid state when they are just formed, and the coating film will level off.

The leveling of the coating film can be measured in the film thickness direction from low to high, using comb scratches with different number of teeth per unit length but equal tooth width and tooth spacing, and the leveling time can be determined according to the groove marks.

2. The causes and countermeasures of orange lines

Orange streak is a common and difficult leveling problem in the painting process. There are many influencing factors, which greatly affect the smoothness of the coating film.

(1) During the spraying process, because the solvent evaporates too quickly, the viscosity of the wet film increases sharply, making leveling difficult and resulting in orange peel. The measure is to choose the appropriate diluent according to the temperature changes of the environment and seasons. For example, the diluents of polyvinyl lacquer are divided into winter use and summer use.

(2) The temperature of the workpiece is too high, so that the solvent evaporates instantly, and the wet film cannot be leveled. The cooling effect of the forced cooling section should be improved so that the workpiece temperature is ≤40°C.

(3) The amount of paint produced during spraying is too small, or the spraying distance is too far, the deposited paint film on the surface is too thin, and leveling becomes difficult.

(4) The atomization of the Spray Gun is poor, and the paint mist particles are too large, which also produces orange lines, reduces the amount of paint output and increases the output of compressed air, and improves the atomization performance. Spraying, when manual touch-up is required, a portable electrostatic Spray Gun is used, and manual touch-up is carried out before automatic electrostatic spraying. Because the mist particles of the manual electrostatic Spray Gun are thicker than those of the automatic electrostatic Spray Gun.

(5) The spraying distance is too close. Although the spraying distance is too close, the thickness of the coating film is good for leveling, but the impact force of the compressed air makes the thick coating film produce larger ripples, which makes the leveling worse. To avoid the hanger Swing, the distance between the Spray Gun and the workpiece surface should be kept within ±5mm.

(6) The viscosity of the paint is too high. When the viscosity of the paint is high, the spray atomization and wet film leveling are poor, because the thinning is carried out according to the construction specifications and the spraying equipment with a constant temperature device is used.

(7) If the ambient temperature is too high, or if the flash-drying time is insufficient, bake it.

(8) The air flow rate in the painting room is too fast, which makes the wet film solvent evaporate quickly and make it difficult to level.

(9) Rough substrates can easily lead to short-wave orange patterns. The surface roughness (Ra) of steel for cars should be less than or equal to 1µm. It plays the role of filling and has good leveling property. It is necessary to improve the cleanliness of spraying, reduce surface particles, and reduce grinding, so as to avoid the damage of the surface of the intermediate coating film and produce orange peel.

(1o) Metal base paint is sprayed too thickly and flash-drying is not sufficient, it is easy to cause roughness and unevenness when varnish is applied alone, so the thickness of metal base paint is likely to be between 12~14µm, try to spray as thin as possible, so that the aluminum powder can be arranged in parallel Sets well after flashing off well.

(11) During drying, the rising hot air flow and direct infrared radiation tend to cause more long ripples on the vertical surface than on the horizontal surface, so the heating period should not be too short, and the heating time should be 7 to 10 minutes. In addition, as much as possible Increasing the thickness of the single-gloss varnish and prolonging the flash-off and leveling time can greatly reduce orange streaks, especially on vertical surfaces.

(12) The deposition of scattered paint mist on the surface of the sprayed paint film is also a factor causing orange streaks. Corresponding measures should be taken to prevent the phenomenon of air, flow and manual overspray in the spray booth.