The air spraying method, also known as air spraying and ordinary spraying, relies on the airflow of compressed air to form a negative pressure at the nozzle to take the paint out of the paint storage tank and atomize the paint into mist. With the help of the airflow, the paint A method of reaching the surface of the object to be coated. The air spraying equipment is simple, easy to operate, easy to maintain, its coating efficiency is high, the workability is good, the paint film obtained is uniform and beautiful, and it can coat 150~200m2 per hour (about 8~10 times of brush coating), suitable for spraying General paint. The disadvantages of air spraying are: the paint needs to be prepared according to the proportion before spraying, and the appropriate viscosity should be adjusted. When spraying, a considerable part of the paint is lost with the diffusion of the air; the film is thin, and it takes multiple spraying operations to reach the specified film thickness requirements. The permeability and adhesion of paint are generally worse than that of brushing; the paint and solvent diffused in the air are harmful to the human body and the environment; in the case of poor ventilation, the vapor of the solvent reaches a certain level, which may cause explosion and fire. With the development of marine and heavy-duty anti-corrosion coatings in the direction of high solid content, air spraying is rarely used in this field.

(1) Equipment and tools for air spraying method

The air spray unit includes:

(1) Spray gun: form the paint into mist and spray it on the surface of the object to be coated;

(2) Compressed air supply and purification system (Air Compressor): supply clean, dry, oil-free compressed air;

(3) Paint conveying device: store paint and supply paint continuously;

(4) Rubber hose: transport compressed air;

(5) Paint spraying room: Install ventilation safety equipment, the indoor temperature is 18~30°C, and the relative humidity is less than 70%.

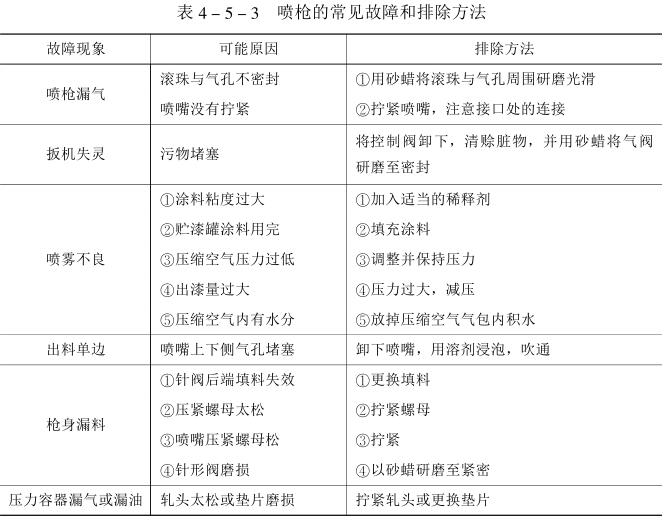

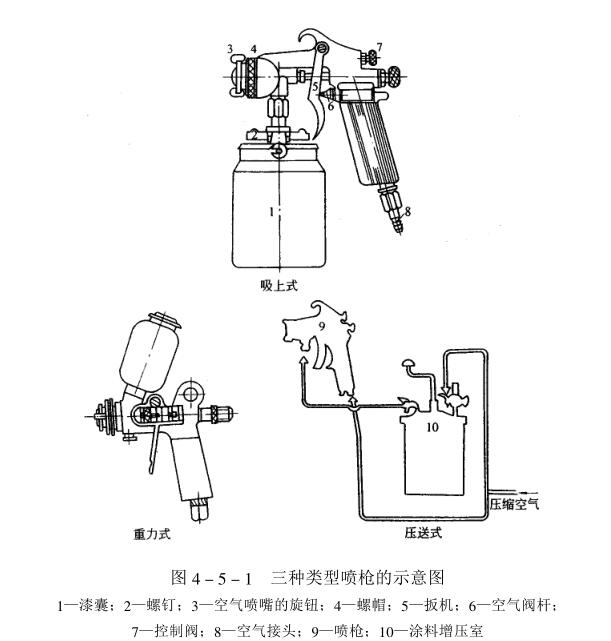

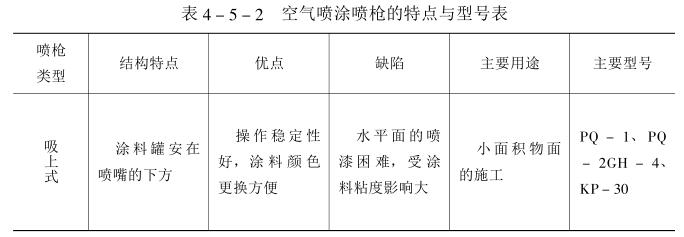

Spray gun is the main tool of air spraying method, and its type, structure and operation greatly affect the coating quality. The Spray Gun is a tool that atomizes and sprays the paint onto the surface of the substrate after mixing the paint with compressed air. There are many types of Spray Guns, which are distinguished according to the way the paint is supplied. There are mainly three types: suction type, gravity type and pressure-feed type. Figure 4_5_1 shows the schematic diagrams of the three types of Spray Guns. Table 4_5_2 shows the characteristics and models of air Spray Guns.

按照上表的各类喷枪的性能特点和涂装对象的需求,按照喷嘴的口径和空气使用量等,合理选择喷枪的类型和规格,选择喷枪时还应考虑喷枪本身的大小和重量,涂料用量、损耗等,喷嘴的口径越大、压力越大,涂料喷出量越大;涂料的粘度越高,涂料喷出量越少,大面积涂装,选用连续供漆系统的喷枪,需用扁平式或稍大孔径的喷嘴;小面积涂装,可采用间断供漆的喷枪、小口径喷嘴,修补时采用口径为0.5mm的圆形喷嘴,喷涂压力可According to喷嘴大小和涂料的性质调节,空气压力过高,雾化虽细,但涂料飞散多,损失大,反之,若压力不足,喷雾变粗,产生橘皮、针孔等缺陷,一般粘度高的涂料采用较高的压力,如膩子喷涂时压力一般为0.34MPa;高粘度涂料压力为0.25~0.3MPa,低粘度涂料为0.1~0.15MPa。

(二)空气喷涂的施工方法

喷漆施工的质量主要决定于涂料的粘度、工作压力、喷嘴写物面的距高,以及操作者的技术熟练程度,为了获得光滑、平整、均匀一致的涂层,喷漆时需要掌握正确的操作方法,,(1)膩子用喷嘴口径为3.5~4.5mm;低粘度涂料用喷嘴口径为1~1.5mm;高粘度涂料用喷嘴口径为2~3mm,喷涂对象与喷嘴的关系:喷涂小面积用喷嘴口径为1~1.5mm;喷涂大面积用喷嘴口径为2.5~3mm;喷涂各种图案、文字,喷嘴口径为0.2~1.2mm。

喷枪与被涂物面的距高对漆膜质量有较大影响。距高太近,漆层增厚,产生流淌、橘皮等现象;距高太远,漆膜变薄,涂料损失大,漆膜易脱落,漆膜不平整,严重时大大降低光泽。一般喷距为200~300mm,小口径喷枪为150~250mm,而大口径喷枪的喷距。

(2)用无名指和小指轻轻拢住枪柄,食指和中指勾住扳机,枪柄夹在虎口中;喷涂时,眼跟着喷枪走,随时注意涂膜形成的状况和喷头的落点。喷枪与物面的喷射距高和垂直角度由身体控制,喷枪的移动同样要用身体来协助臂膀的移动,不可移动手腕,但手腕要灵活。

(3) When the Spray Gun is running, the Spray Gun should be kept at right angles to the surface of the object to be coated and run in parallel. The moving speed of the Spray Gun is generally adjusted within 30~60cm/s, and it is required to keep moving at a uniform speed as much as possible. The distance between the Spray Gun and the surface to be coated is between 20 and 30cm.

(4) During operation, the edge of each spraying range should be repeated 1/3~1/2 on the edge of the previously sprayed range, and the width of the border should be consistent. If the width of the boundary is variable, the film thickness will be uneven, and streaks and marks may occur.

(5) In order to obtain a more uniform coating and better anti-corrosion effect, when spraying the second coat, it should cross the previous paint film vertically and horizontally, that is, if the first coat is sprayed horizontally, the second coat should be sprayed vertically spraying.

(6) When spraying each time, the Spray Gun trigger should be turned on when the Spray Gun is moving, and the Spray Gun trigger should also be turned off when the Spray Gun is moving, so as to avoid excessive accumulation of paint on the surface of the workpiece and sagging.

(7) After spraying, the excess recyclable paint should be returned to the original paint bucket, and then the Spray Gun should be cleaned, and no residual paint in the Spray Gun is allowed. When cleaning the Spray Gun, the corresponding thinner of the paint can be poured into the paint tank, the trigger is pulled, and the solvent is sprayed out from the nozzle of the Spray Gun, so that the paint pipeline can be cleaned. Then turn off the compressed air, remove the Spray Gun and wipe it clean with solvent. Clean the air cap, nozzle, and gun body carefully with a brush with solvent. When the air hole is blocked, it needs to be dredged with a cork needle. Check the tightness of the needle valve backing ring and the air valve backing ring, paint on the sealing rings, and hang them.

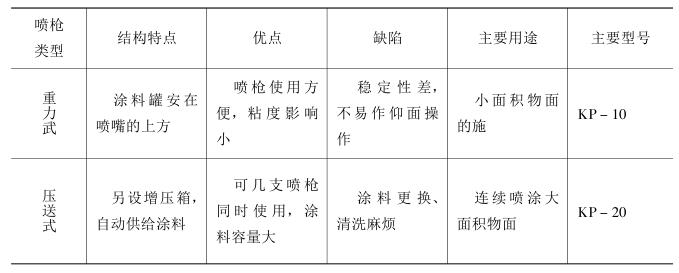

(8) See Table 4_5_3 for common faults and troubleshooting methods of Spray Guns.