The sag phenomenon during coating construction is closely related to the flow characteristics of the coating. Here, an appropriate model is established for the sag phenomenon to analyze and deal with, so as to obtain the basic parameters that affect the sag behavior.

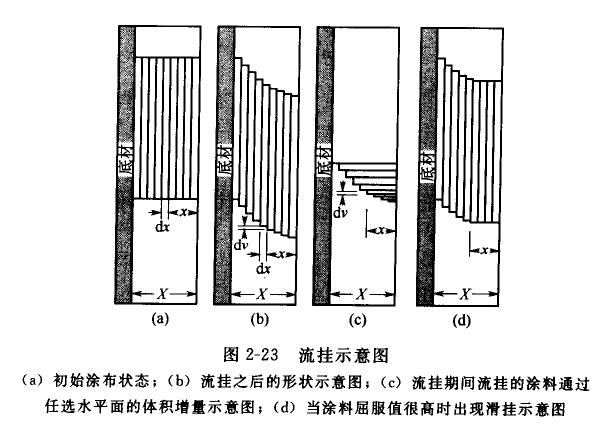

A wet coating of density ρ applied on a vertical surface can be regarded as consisting of many very thin layers. Assuming that the area of each layer is A, the thickness is dx, and a thin layer at a distance x from the outer surface of the wet film, the friction between it and the outer layer makes it support the outer layers and compete with gravity [Figure 2-23( a), (b)]. The sagging pull it is subjected to is:

It can be seen that the amount of sag increases linearly with the increase of the coating width; while the thickness increases, the amount of sag will increase exponentially. For example, during a certain construction, the thickness of the coating film somewhere above is twice that of the lower layer, and for the lower layer, the amount flowing down from top to bottom is 8 times more than the amount flowing away from it, which will almost certainly lead to Sagging. Therefore, during coating construction, it must be carefully coated to form a uniform coating, and increasing the viscosity of the coating is also a feasible method.

If the coating has a significant yield value, the paint film applied on the vertical surface will not show the above-mentioned sag phenomenon, but will move as a whole with a thicker layer of thickness x. This phenomenon is called sag [Fig. 2-23(d)]. The thickness of the sliding hanger is:

When the yield stress is large enough, it is possible to make .x=X, at this time, the rate of downward movement is 0.

The two goals of minimum sagging and leveling as much as possible are opposite to each other, such as reducing viscosity, although it is beneficial to leveling, it also promotes sagging. Alternatively, increasing the film thickness to accelerate leveling will increase the degree of sagging. This conflicting outcome means that in practice some compromise is required to achieve satisfactory leveling without excessive sagging. A small amount of sag is usually tolerated in order to achieve proper leveling without serious consequences. For high solids coatings, only pseudoplastic systems can provide sag control, leveling and sprayability simultaneously.