In the process of paint construction and molding, there are often paint accumulations and edge thickening on the edges of the template or parts. Even if the wet paint film itself is very uniform, without sagging, and without thick edges, etc., during the baking or drying process, There tends to be a thick edge called a "picture frame" form. This phenomenon is caused by surface tension gradients.

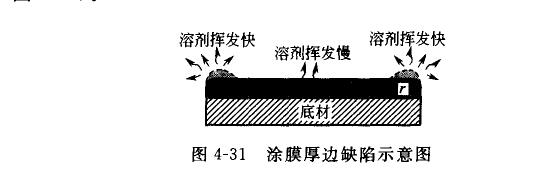

We already know that the vapor pressure of a solvent is related to its liquid level. The vapor pressure of a convex surface is higher than that of a flat surface, and the smaller the radius of curvature of the convex surface, the greater the vapor pressure. Therefore, at the edge of the sample or part, the coating film is in a convex surface state, and its radius of curvature is small, so the solvent there often evaporates faster. If the surface tension of the solvent is lower than the surface tension of the system resin and pigment, the surface tension at the edge increases more than the inside, and there will be a gradient in which the surface tension gradually decreases from the edge to the inside, and the part with low surface tension in the middle will move toward the edge. Flow at high surface tension causes edge thickening (Figure 4-31).

In the coating film, due to the initial unevenness of the surface, the solvent on the convex surface volatilizes faster than the solvent on the concave surface, so the ridges also have higher surface tension, as a result, a surface tension gradient from the convex to the concave will be formed. The coating film at the convex will migrate to the convex, making the convex more convex and the concave more concave. This effect is opposed to the overall leveling power, resulting in the disadvantages of concave and convex surfaces.

To overcome the above-mentioned two kinds of film disadvantages, it is necessary to make the surface tension of the solvent equal to or higher than that of other components in the system. If some surfactants are added to the coating, the system can maintain the original surface tension after the solvent volatilizes, and the surface tension gradient can be significantly reduced, thereby improving its overall leveling property.

Since the surface tension always makes the liquid coating film have the smallest surface area, the coating will reduce its surface area by "beading" at the edge of the sharp edge, resulting in poor edge coverage. Accompanied by this phenomenon, thick accumulation often occurs behind it, forming surface defects of the picture frame. Too thick or too thin often appear at the same time, affecting appearance and performance. For this situation, it can be improved by a small amount of surfactants such as silicone oil, but this can only reduce the surface tension and reduce the extent of this phenomenon, so that the force of the coating to reduce its surface area still exists. Adding a thixotropic agent is more effective because it can prevent the flow of paint to the edge area caused by surface tension.