(1) The principle and characteristics of air spraying

High-pressure air spraying is to use the negative pressure generated when the air is sprayed from the nozzle to suck out the paint in the tank, and the sucked paint quickly diffuses and flies to the surface of the workpiece in the form of paint mist to form a continuous coating film.

High-pressure air spraying has the following characteristics.

① The equipment is simple and practical. The price of the air Spray Gun is relatively low. It can be combined with an Air Compressor to form a spraying system, which can conveniently complete the spraying work in different places.

② Strong operational adaptability Air spraying is suitable for almost all kinds of coatings and objects to be coated, and requires low training for workers.

③The coating film is of good quality, the atomization effect of air spraying is better, and a uniform and beautiful coating film can be obtained after spraying.

④High coating efficiency Air spraying can spray 1a~200m workpiece per hour, which is about 8~10 times of brush coating. However, the air Spray Gun requires frequent feeding, which affects the working efficiency and the labor intensity of the workers is high.

⑤Low paint utilization rate Air atomization causes paint to scatter around, wasting paint, and the paint utilization rate is only about 50%. The flying paint pollutes the working environment and causes human injury.

(2) Air Spray Gun

1) Type of Spray Gun

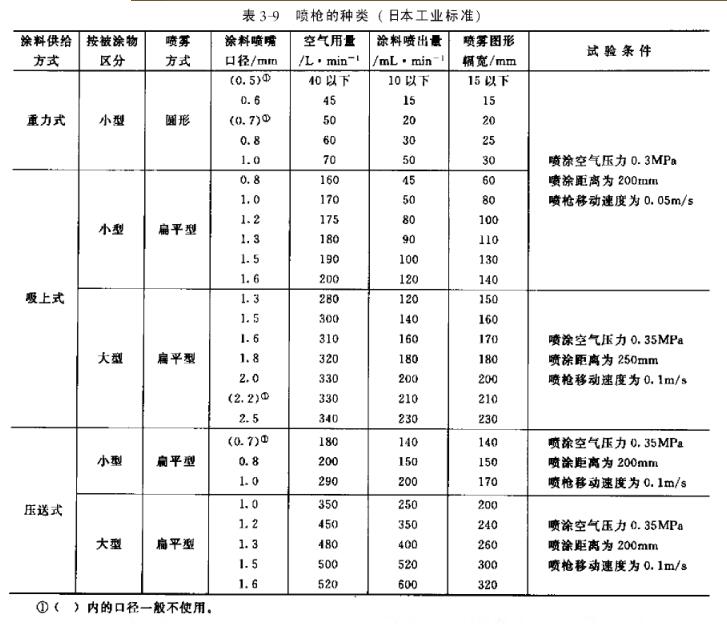

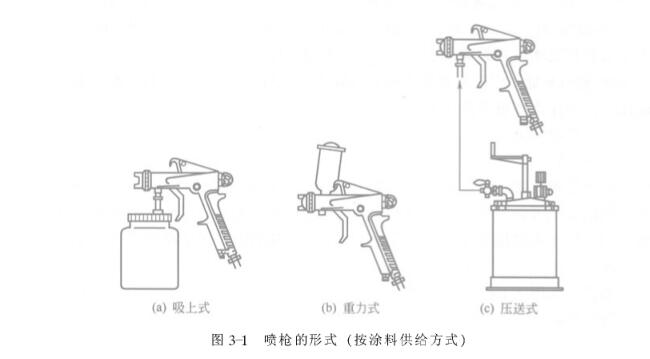

Spray gun is an important equipment that determines the quality of spraying. According to the supply mode of compressed air, it can be divided into internal mixing type and external mixing type; according to the supply mode of paint, it can be divided into three types: gravity type, suction type and pressure feeding type. Gravity Spray Gun is mainly used for spraying sample and small area repair. The suction Spray Gun is mainly used for small batch production, and the pressure feed Spray Gun is suitable for large batch industrial coating. See Table 39 for the types of Spray Guns.

The form of the Spray Gun is shown in Figure 3-1.

2) Spray gun structure

The Spray Gun is composed of three parts: the spray head, the adjustment mechanism and the gun body. The structure is shown in Figure 3-2.

The spray head is composed of paint nozzle, air width and needle valve, etc. It is the key component to determine the paint atomization and spray pattern. The adjusting mechanism can adjust the ejection volume of paint and air, and can also adjust the size of the spraying fan. The gun body is equipped with a trigger for opening and closing the needle valve and a seal to prevent 1, Shilu paint and air, and is made into a shape that is easy to hold, so as to facilitate construction operations.

Spray gun nozzles are generally made of alloy steel, and are heat treated to increase their service life. The diameter of the nozzle has a variety of specifications from 0.5 to 5.0 mm. Generally, the diameter of 0.5 to 0.7 mm is used for spraying paints such as colorants and shellac; the diameter of 1.0 to 1.8 mm is used for nitro paints and synthetic resin paints. The caliber of 2.0~2.5mm is used for viscous paints such as orange paint ; the caliber of 3.0~5.5mm is used for viscous paints such as plastisol and anti-stone impact paint.

Spray gun nozzles are generally made of alloy steel, and are heat treated to increase their service life. The diameter of the nozzle has a variety of specifications from 0.5 to 5.0 mm. Generally, the diameter of 0.5 to 0.7 mm is used for spraying paints such as colorants and shellac; the diameter of 1.0 to 1.8 mm is used for nitro paints and synthetic resin paints. The caliber of 2.0~2.5mm is used for viscous paints such as orange paint ; the caliber of 3.0~5.5mm is used for viscous paints such as plastisol and anti-stone impact paint.

空气幅的主要作用是将涂料雾化,并形成所要求的喷雾图形及效果。空气幅上有喷出压缩空气的中心孔、側面空气孔和捕助空气孔。孔的位置、数量和孔径等因用途不同各有差异。空气幅种类如图33所示。中心孔与涂料喷嘴是同心圆,其间隙为0.15~0.3mm。中心孔喷出压缩空气在涂料喷嘴的前端形成负压区,负压的作用是使涂料吸出喷成圆的喷雾图形。側面空气孔喷出压缩空气将从中心孔喷出的圆形喷雾图形挤压成所需的形状。空气幅側面空气孔的作用如图3-4所示。捕助空气孔喷出压缩空气使空气幅喷出的空气量与压力均衡,调节喷雾图形的大小并保持稳定,还可促进涂料雾化,并吹掉涂料喷嘴上的残余涂料。

空气幅有少孔型和多孔型西种。少孔型有一个中心孔,西边各有图3-4空气帽側面

空气孔的作用

一个捕助孔,其特点是空气用量少,但雾化能力差,涂者效率低。多孔型有多个空气孔和捕助孔,其特点是空气用量大,雾化能力好,涂者效率高。

针阀由喷嘴内部的阀针与针阀杆组成。当扳动扳机使阀针后移时,涂料通道打开涂料即喷出。喷嘴与针阀应配合好以防闭合后涂料泄漏。

调节机构包括空气量的调节机构、喷雾图形的调节机构和涂料喷出量的调节机构。

空气量的调节机构位于喷枪的下部,旋动旋钮即可调节压缩空气的喷出量和压力。没有空气量调节机构的喷枪需要在枪外增加減压阀以调节压缩空气的喷出量和压力。

喷雾图形的调节机构位于喷枪的最上端,旋动旋钮即可调节側面空气孔的空气流量,当側面空气孔全部关闭时,喷雾图形呈圆形;当适当增加側面空气孔的空气流量时,喷雾图形逐渐变成椭圆形。

涂料喷出量的调节机构位于喷雾图形的调节机构的下方,旋动旋钮即可调节喷嘴开启的大小,控制涂料的喷出量。

所有的调节机构和枪罐全部装在枪体上,扣动扳机即可调节压缩空气和涂料的喷出。当扳机扣动时,压缩空气先喷出,继续扣动扳机,涂料才喷出。当松开扳机时,涂料先停止喷出,然后压缩空气再停止喷出。

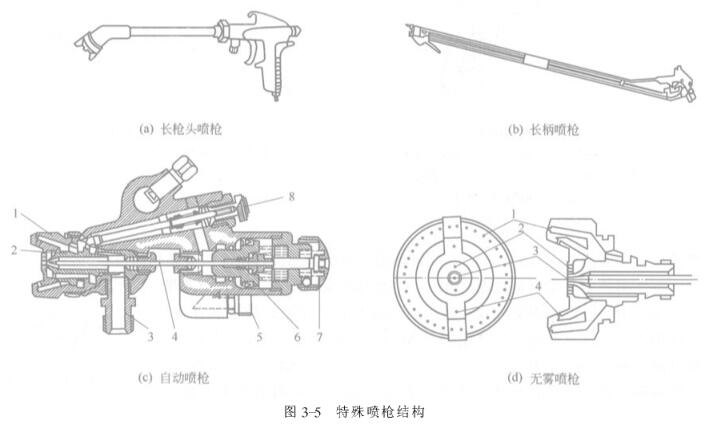

为适应不同场合的特殊用途,还有各种特殊喷枪。常见的特殊喷枪有长枪头喷枪、长柄喷枪、自动喷枪和无雾喷枪。长枪头喷枪适合于管道内壁及死角的涂装;长柄喷枪适合于高空作业的涂装;自动喷枪适合于连续化自动喷涂;无雾喷枪适合于提高涂料利用率。特殊喷枪结构如图3-5所示。

近几年出现了一些新型喷枪,现简单介绍如下。

①HvLP空气喷枪HvLP是英文HighV0lumeL0wPressure的缩写。它是利用空气幅限制空气压力(101bf/in2以下),达到減少涂料反弹或过喷的日的,同时增加空气流量以补偿压力损失而达到雾化所需的能量。HvLP喷枪将涂料的利用率提高到65%,同时涂料的过喷量減少,降低了污染。但HvLP喷枪存在西大缺点:一是无法喷涂高黏度涂料,因喷涂是借助于高空气量及低空气压力将空气雾化,而非传统空气喷涂的高雾化压力,因此对黏度有所限制。一般黏度超过18s(涂4杯黏度计,25°c)便无法获得好的雾化效果;二是需要空气量大,增加了投資成本,相对于传统空气喷涂8~17ft3/min(1ft=0.3048m)的空气消耗量来说,HVLP喷枪12~25ft3/min的空气消耗量明显大出很多,需要换用更大的空压机。

②LVLP空气喷枪LVLP是英文L0wV0lumeL0wPressure的缩写。其雾化压力为10~211bf/in2,与HVLP差别不大,但空气消耗量却只有12~17ft3/min,可喷涂涂料的黏度达到25s(涂一4杯黏度计,25°c),涂料的利用率达到65%。其缺点是由于以低压、低空气量雾化,其喷涂速度明显较传统空气喷涂差很多,影响了施工速度,增加了生产成本。

③LVMP空气喷枪LVMP是英文L0wV0lumeMediumPressure的缩写,是通过独特的空气幅及枪体结构设计,使喷涂时的速度及雾化效果均优于HvLP和LvLP,且空气消耗量只需9~12ft/min,有效地降低了能源的消耗。LVMP的雾化压力为301bf/in,尽管比LvLP高一些,但其涂料的利用率却能达到72%,是日前较好的一种空气喷涂技术。

3)空气喷涂喷枪的维护

a.喷枪喷涂后应立即用所喷涂涂料的配套溶剂清洗干净,特别是双组分涂料,由于涂料采用固化剂固化,如不立即清洗,涂料会在枪内固化,造成喷枪报废。

b.空气幅、喷嘴等应用毛刷藤溶剂清洗。空气孔i者塞时应用软木针疏通,不可用钢钉等金属器具清理,否则会损坏空气孔或造成空气孔出气不均,影响涂料的雾化效果。

c.涂料调节螺性、空气调节螺性及枪体内部的弹簧应定期涂油,进而保证活动灵活并防止生锈。

d.不可将枪体及配件长期浸泡在溶剂中。

e.使用时应轻拿轻放,避免碰伤或挥伤。

4)选择喷枪的原则

①喷枪的型式重力式喷枪主要用于涂料使用较少、颜色更换频繁的场合,涂料利用率高,所用涂料可完全用光,也较适用于试验室的喷涂,但不适用于仰面喷涂。另外重力式喷枪的重心较高,不适用于长时间的连续喷涂。

吸上式喷枪主要用于涂料使用量稍大、颜色更换频繁的场合,中、小批量生产一般都用这种喷枪。

压送式喷枪主要用于涂料使用量大、颜色较为单一的场合。由于不带罐,枪体质量较轻,使用比较方便,由于不要频繁加涂料,操作效率较高。

②喷枪的大小小型喷枪枪体质量轻,主要用于喷涂比较复杂的工件及试验室喷涂样板,但由于出涂料量及出气量较小,操作效率较低。大型喷枪主要用于喷涂量较大平面度较多的场合,操作效率较高。

③喷嘴口径喷嘴口径应According to工件的大小及形状、喷涂作业的工作量、涂料的品种等选择。一般工件小或复杂的工件应用小口径喷嘴,喷涂作业工作量较大的场合选择较大的喷嘴,橘纹涂料宜选择2.5~3mm的喷嘴。在雾化性要求较高的场合,应选用较小的喷嘴。

(3)空气喷涂的作业要点

In the operation process of air spraying operation, spray distance height, Spray Gun operation mode, spray pattern overlap and paint viscosity are the four main points of spraying, which are also the basis of spraying technology, and need to be mastered.

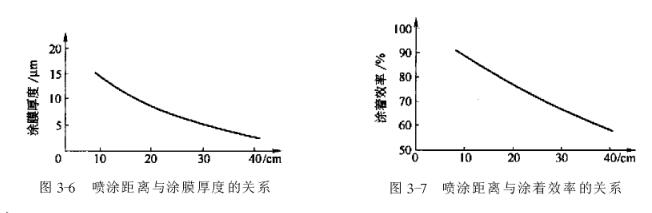

①Spray height refers to the distance between the gun head and the object to be coated. Generally, the spray distance height of the Spray Gun with a caliber below 1.5mm is 15~20mm; the spray distance height of the Spray Gun with a caliber higher than 1.5mm is ~30mm; the spray distance height of the air atomized portable electrostatic Spray Gun is 25~30mm. During the spraying process, the constant spraying height is an important factor to ensure the uniform thickness of the coating film. To achieve this, the Spray Gun needs to be perpendicular to the object to be coated during spraying, and the running track should be kept parallel to the object to be coated. If the Spray Gun and the object to be coated run in an arc during spraying, there must be a large difference in the thickness of the central part and the west side of the sprayed workpiece. Under the same conditions, if the spraying distance is too high, the paint will easily form pools and sag; if the spraying distance is too high, the coating film will become thinner, the paint will be wasted, and it will easily cause coating defects such as void paint. The relationship between the height of the spraying distance, the thickness of the coating film and the efficiency of the coater is shown in Figure 36 and Figure 3-7.

② The running mode of the Spray Gun includes the angle between the Spray Gun and the object to be coated and the running speed of the Spray Gun. The Spray Gun and the object to be coated should be at right angles and run vertically. If the Spray Gun is inclined or runs in a circular arc, a uniform thickness of the coating film cannot be obtained. The running speed of the Spray Gun is generally controlled within the range of 30~60cm/s, and the actual running speed is determined according to the amount of paint sprayed and the complexity of the workpiece.

③ Spray pattern overlap refers to the partial overlap of the sprayed spray pattern. The degree of overlap should be consistent, and the degree of overlap between the front and rear is generally 1/4~1/3 of the effective spray pattern range. If the degree of overlap is variable and the film thickness is uneven, streaks or spots can occur.

(4) Paint viscosity

The paint construction viscosity needs to be adjusted within the range stipulated by the process. When the viscosity is too high, the atomization of the paint is poor, the paint is not easy to spray out, and defects such as orange peel are easy to occur; when the viscosity is too low, the thickness of one spray is thin, and defects such as sagging are easy to occur.

The construction viscosity of different types of coatings is not the same, and the construction viscosity should be determined according to the construction requirements of the coating during construction.

(5) Common faults and prevention during spraying

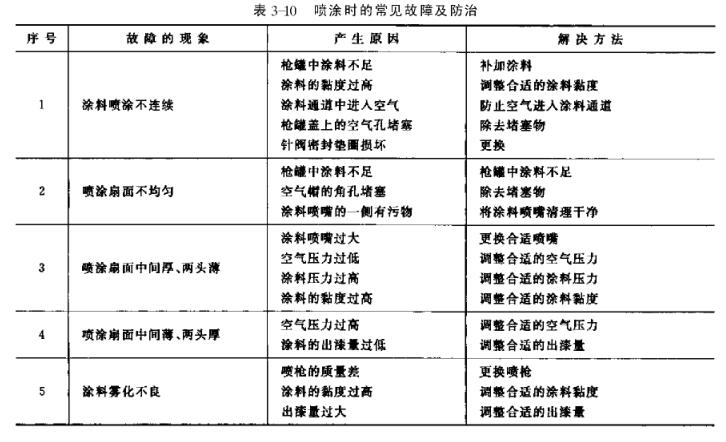

See Table 3-10 for common failures and their prevention during spraying.