In the daily crossing test, due to the wear and tear of the blade of the paint film crossing device for a long time, there may be an error between the cutting tool spacing and the product when the product leaves the factory. At this time, it is necessary to check the blade on the paint film crossing device. to calibrate.

The calibration of the paint film cross-cutting device is generally required only when the blade error exceeds 0.01mm. The calibration can use a tool microscope or an image measuring instrument with a division of 0.001mm and an accuracy of 3μm as a calibration tool.

Calibration method of paint cross-hatcher

1. Take off the blade on the cross-cutting device and clean it, place it on the instrument platform for calibration, and find the image of the cutting blade in the field of view under an isothermal environment of 20°C.

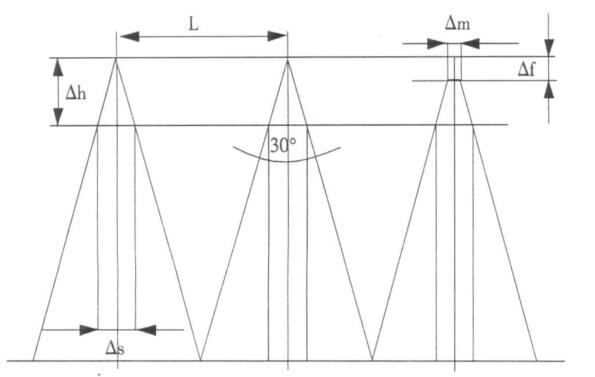

2. As shown in the figure, take the cross-cut cutting tool with 2mm spacing as an example, because it is suitable for 60-120μm coating thickness, the effective working tooth height is △ h≤0.12mm, considering the wear of the top of the tooth during the cutting process Even distorted, the distance L between the center line of the tooth width △ s at △ h and the center line of the adjacent tooth width is the distance between the cutters, and the maximum difference between the distances is the distance error.

3. As shown in the figure, after aligning the tooth top, △ f is the straightness of the tooth top; the maximum difference of each tooth △ h from the tooth width △ s is the working tooth width difference of the cutter; the maximum cutting edge of the tooth top The width △ m is the width of the tooth top cutting edge.