The firmness of the bond between the paint film and the surface to be coated is called adhesion. Adhesion is an important index of paint. The firm adhesion of the paint film is an important basis for the paint to realize the protection of the base material. Therefore, the determination of paint film adhesion has been widely concerned by the paint and coating industry.

1. Determination of paint film adhesion

At present, there are 3 effective paint film adhesion measurement standards:

GB/T1720-1979 (1989) Determination of paint film adhesion;

GB/T5210-1985 Determination method of coating adhesion pull-off method,

GB/T9268-1998 Cross-cut test of paint and varnish film.

(1) GB/T172o-1979 is the traditional measurement method of paint film adhesion, which is transformed according to the original Ministry of Chemical Industry standard HGZ-462-78. In this method, a special adhesion Tester is used to draw a circular rolling line on the paint film sample, and the adhesion is evaluated according to the integrity of the paint film within the scratch range of the circular rolling line. This method is familiar to professionals in the paint and coating industry due to its simple operation, intuitive evaluation method, and the lack of other measurement methods for a long time, and it is still widely used now.

(2) GB/T5210-1985 refers to the adoption of international standards

ISO4624:1978 "Paints and varnishes - Pull-off test method for adhesion".

The pull-off method to measure the adhesion is to use an adhesive to connect the special sample painted on the surface on the centering device, and then apply a vertical and uniform tensile force on the bonding surface of the sample at a specified speed (10mm/min). , to determine the force required for the adhesion between coatings or between coatings and substrates to break, expressed in kgc/m:.

When measuring the adhesion, pull it apart on a Tensile Testing Machine to produce adhesion failure, cohesive failure, and cementation failure.

The test results are expressed as a combination of adhesion and failure modes.

This method is a method for quantitative determination of adhesion. It is suitable for the quantitative determination of the adhesion between single-layer or composite coatings and substrates or coatings. It has significant significance for studying coating adhesion and comparing coating properties. At present, there are only 8 national paint standards with this quantitative standard, and the adhesion of a large number of paint products has no quantitative index, so the use of this standard is not common.

2 Paint film cross-hatch test

GB/T9286-1998 is equivalent to the international standard ISO

GB/T9286-1998 is equivalent to the international standard ISO

2409:1992 "Paints and varnishes-Cross-cut test" (Second Edition) replaces and equivalently adopts GB9286-88 of 1502409:1972.

This standard specifies a test method for assessing the resistance of a coating to detachment from a substrate .

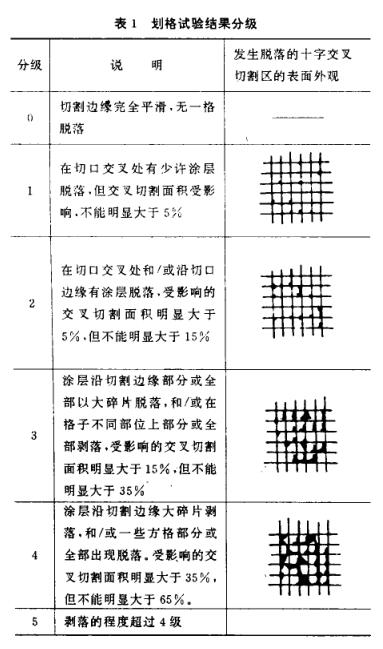

This standard stipulates that 6 parallel cutting lines are cut vertically (the spacing is determined by the thickness of the coating and the hardness of the substrate). Use a transparent adhesive tape to paste the cut part of the coating (the soft substrate does not need an adhesive tape), tear off the adhesive tape evenly, and check the test results for the damage of the cut coating. ~Level 5. Level intact (see table) l. For general use, the first three grades are satisfactory. The first three levels are also used when passing/failing is required.

The main differences are:

(1) The new standard stipulates that the cutting number is 6, while the original standard stipulates that it is 6 or 11,

(2) The new standard stipulates the cutting spacing, which depends on the coating thickness and substrate type

(3) The new standard only stipulates the operation procedure of manual cutting, while the original standard also stipulates the operation gallery of mechanical cutting. Therefore, the new standard is more simplified and more operable. The method of scratch test has long been used in the world. The American National Standard ANsl/ASTMD3359-87 "Measurement of Adhesion with Tape Test" stipulates two methods of drawing X and drawing 6 or n grid patterns of orthogonal incisions on the coating film, stick the tape on the incision and tear it off Score the adhesion result. ~Level 5. Level 5 is better, intact.

In addition, the Japanese Industrial Standard IJSK54. . -90 "General Test Methods for Coatings" also specifies the substrate cross-hatch method and the substrate cross-hatch tape method for the adhesion test. Press the result. , 2468, 10 points, a total of 6 levels of evaluation l. The point is better, intact.

Although the cross-cut test is a commonly used adhesion determination method in the world, GB/T9286-1998 clearly points out that the performance measured by this empirical test depends on the adhesion of the coating to the previous coating or substrate. , also depends on other factors. Therefore "this test procedure cannot be considered as a method of determining adhesion".

Therefore, this method should be called "scratch test" or "paint film scratch test" instead of "adhesion" or "determination of adhesion".

Since my country's first paint film cross-cut test standard GB9286-88 was released in 1988, the cross-cut test has attracted widespread attention in CHINA. Among the national standards and industry standards for coatings released after 1988, there are 22 standards that use "cross-cut test", but only 2 standards that use "adhesion". It can be seen that the scratch test is gradually replacing the adhesion determination.

When adopting the scratch test method, attention should be paid to:

(1) This method is not suitable for coatings with a film thickness greater than 2501 μm, nor for textured coatings.

(2) This method is suitable for coatings on hard substrates (steel) and soft substrates (wood and plastic), but these different substrates require different test procedures.

(3) The cut-off test needs to be completed by experienced personnel. In the standards that have adopted the cross-cut test, the expressions "adhesion (scratch test)" and "adhesion measurement shall be carried out according to the provisions of GB/T9286" occupy a considerable proportion. This term does not conform to the provisions of the standard itself and should be noted.