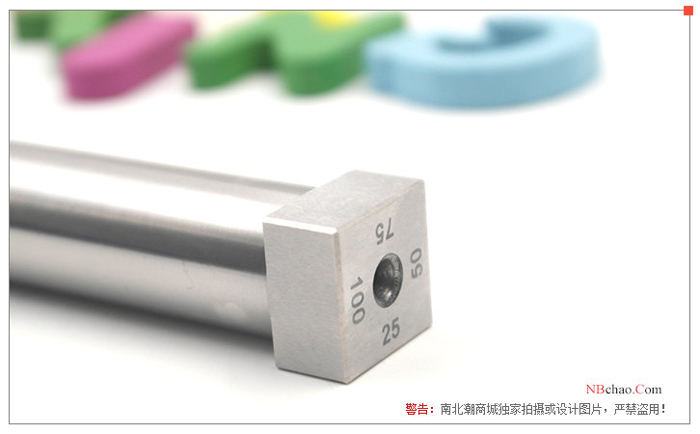

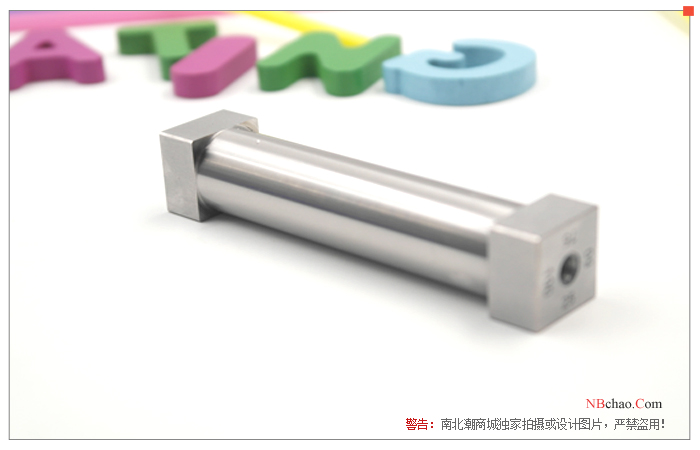

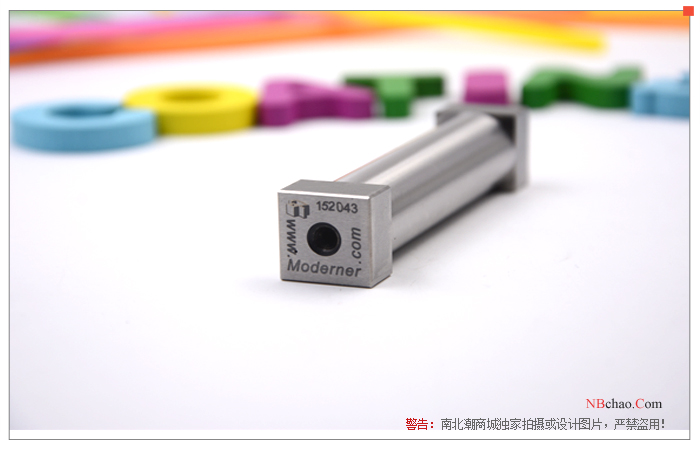

Wet film Applicator is made of tool alloy steel and tool carbon steel. Due to the characteristics of surface grinding and mirror polishing, it is usually used to coat a wet film with a specified thickness to maintain the color and hiding power of the sample. Or prepare samples, etc.

This issue mainly conducts an unpacking inspection of the quadrilateral Wet Film Applicator in the modern environment. The operation method is very simple. Firstly, place the sample on the platform and fix it, select the appropriate Applicator according to the required wet film thickness, then place samples in front of the Wet Film Applicator, hold the two ends of the Wet Film Applicator, It has been sliding at a constant speed of 150mm/s. In this way, the desired wet film thickness can be prepared.

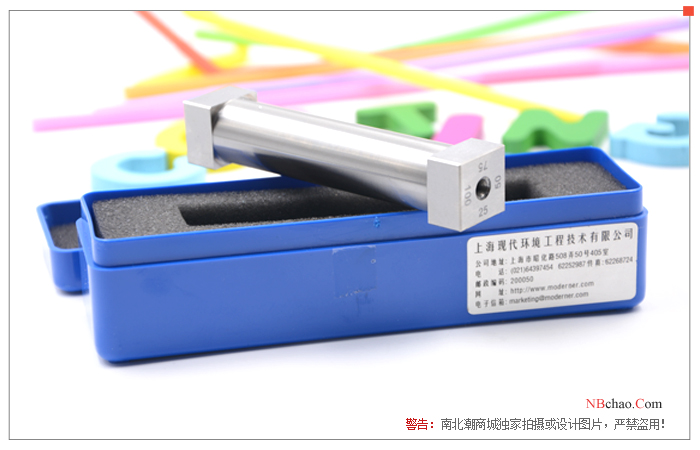

Next, please follow the editor to appreciate a group of manual inspection and unboxing pictures↓↓↓

This is the end of the beautiful picture appreciation in this issue, and it will continue in the next issue~