Electrophoretic topcoats include transparent electrophoretic topcoats and electrophoretic topcoats with hiding power. The former is composed of soluble resin or soluble resin added with soluble dyes. It has uniform color, strong durability and is not easy to peel off. It mainly includes gold, red copper, antique copper and black colors, etc.; Composition, such as white, light black, sub-black, blue and brown, etc.

Transparent electrophoretic coatings are mainly used for anti-oxidation, and can be coated on silver (or silver-plated), copper (copper-plated), aluminum, zinc alloy, imitation gold electroplating and aluminum oxide layers, etc. Prevents discoloration of the coating or substrate. Because the characteristic of polyurethane l11 resin coating is that it will not turn yellow under sunlight, and its own transparency is very high. But it should be noted that the substrate needs to be treated effectively before painting, otherwise the defects of the bottom layer will be fully revealed or even aggravated. This process can replace electroplating.

The non-transparent electrophoretic topcoat can be painted directly on the substrate, and its construction characteristics are similar to the electrophoretic primer.

The coating principle and influencing factors of the electrophoretic topcoat are similar to those of the electrophoretic primer, so they will not be described in detail. The process flow and process conditions are briefly introduced for comparison.

1) Basic process conditions

Pretreatment (including degreasing, pickling, polishing, electroplating or phosphating, etc.) - pure water washing - electrophoresis - recovery - cosolvent + pure water washing - pure water washing - drying (baking conditions 130°C/0.5h or 160°C/15min ).

2) Process conditions

Solid content 8%~12%, pH value 3.5~4.5 (25°C), conductivity 400~600MS, milliequivalent (MEQ): 30~50 (solid content 10%), temperature 10~23°C ( 21~23°C), the electrophoresis time is 20~60s (generally 20~30s), the construction voltage is 20~50v (usually 25v~30v, the coating is about 10µm), the coating thickness is 5~25µm, and the electrode ratio is 11~ 21. The curing condition is 130~160°C/15~30min (workpiece temperature), the ultrafiltration membrane pore size is 1µm, and the pole distance is not less than cm.

3) Example of electrophoresis process

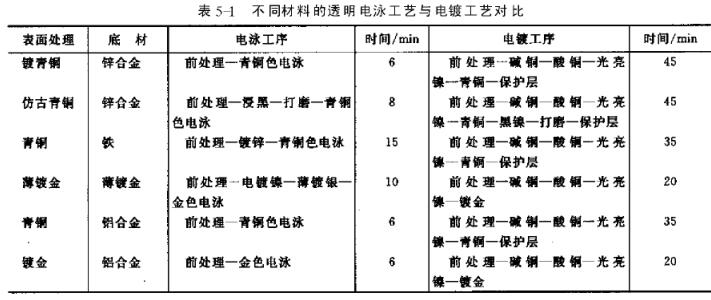

The comparison of transparent electrophoresis process and electroplating process for different materials is shown in Table 5-1, which shows the superiority of this process.

Generally, copper-colored electrophoresis can be electrophoresed directly on well-polished zinc and aluminum alloys or bright zinc-plated iron, but the polishing needs to be good; electrophoresis gold on iron parts needs flash silver plating; electrophoretic coatings of the same color can be used on different metals or electroplating layers On the surface, there will be shades of color; clear electrophoretic coatings cannot cover the underlying metal flaws. Opaque electrophoretic coating, the metal bottom layer does not need to be electroplated, just slightly polished.