Tinplate, also known as tin-plated iron, is also called tin-plated iron because its surface is coated with a layer of tin to prevent corrosion and not easy to rust. Also because of its corrosion resistance and easy processing characteristics, it is widely used in the food packaging industry. In the paint and ink industry, iron plates are cut into different specifications for various experimental coating tests.

This issue mainly conducts product evaluation and inspection on Tewoz/OTZ tinplate for reference of relevant users in the industry.

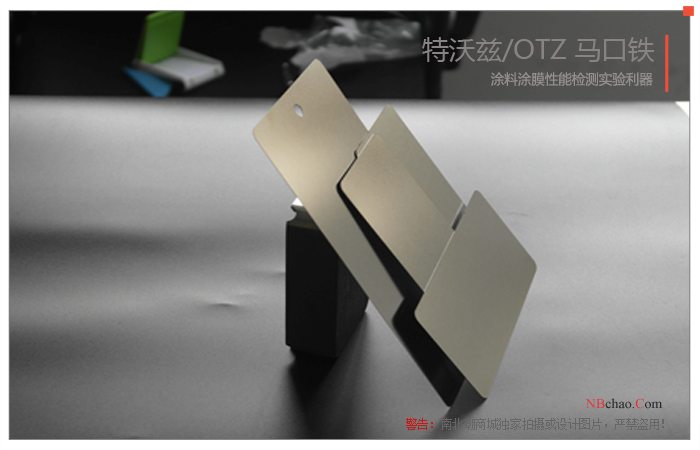

<1> Tewoz/OTZ tinplate mainly includes two types: perforated and non-perforated. In the performance testing of industrial coatings (adhesion, hardness, impact, flexibility, bending, drying time), the coating film is required to be prepared on a tin plate.

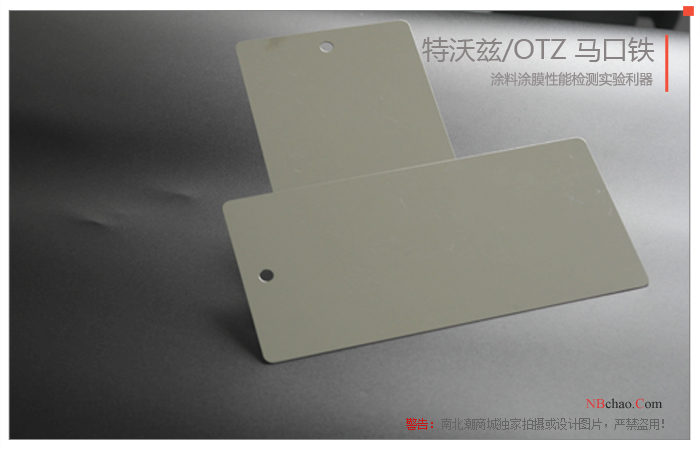

<2> Some customers have responded, why does the surface of the received tinplate feel greasy? That is ink, to avoid rusting during storage and transportation, so that the tinplate can be easily peeled off layer by layer during printing.

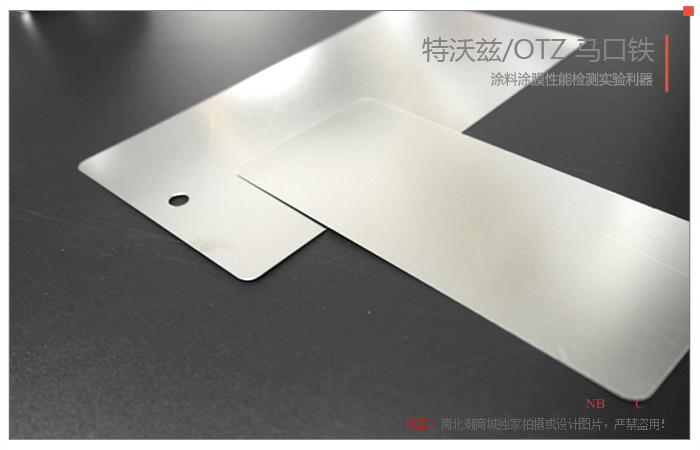

<3> Tinplate needs to be processed before printing, including dust removal, wrinkle removal, oil removal, polishing, oxidation treatment, sandblasting, surface coating, etc. Dust removal and wrinkle removal are to remove dust, metal shavings and other dirt on the surface, and wrinkle removal is to improve the smoothness of the surface. Degreasing is to eliminate oil stains on the metal surface to improve ink adhesion.

<4> Since tinplate is a non-absorptive material, it is necessary to coat a layer of coating film on its surface before printing to make it firmly adhere to the surface of tinplate, and at the same time, it can adhere and bond with the ink printed on its surface.

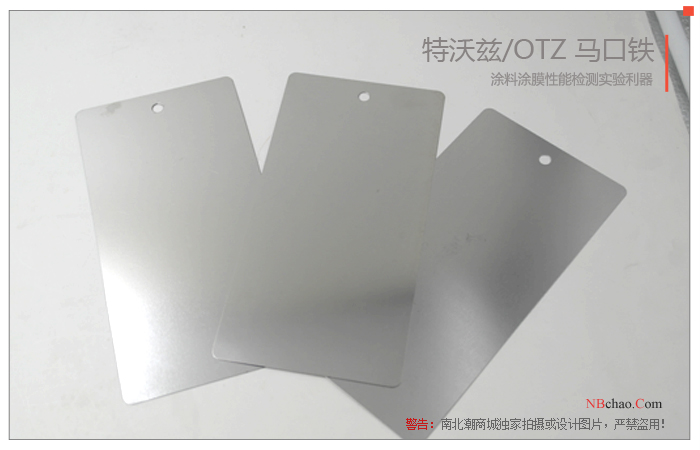

<5> The adhesion of the ink coating on the surface of the tinplate will be related to the surface properties of the tinplate product itself. The ink used in the printing process, the type of coating, the baking temperature and the thickness of the ink coating will all affect the Tinplate adhesion has an impact.

<6> Tinplate will encounter many problems during the coating process, such as large amount of coating film, air wrinkles, tin melting, missing coating, uneven coating, zebra stripes, and creeping lines. There are different problems in tinplate coating, and it is necessary to choose the corresponding solution according to the specific situation.

The product evaluation of this issue is over, and the next one is expected to continue~