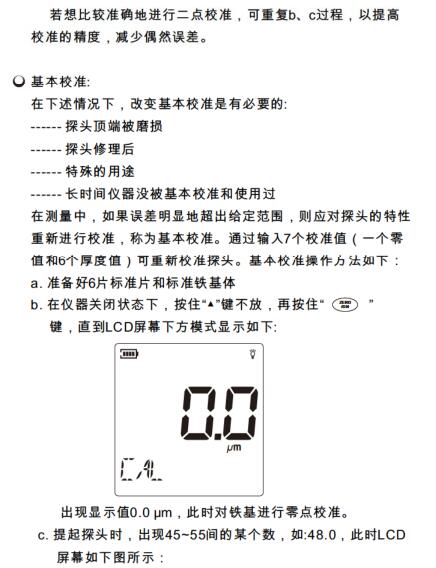

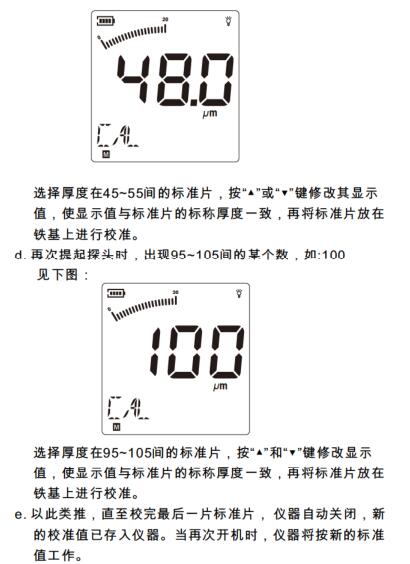

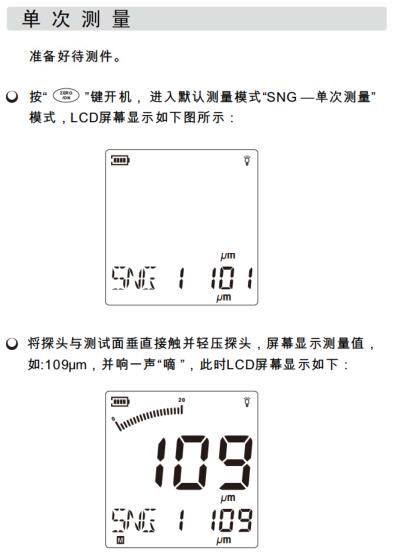

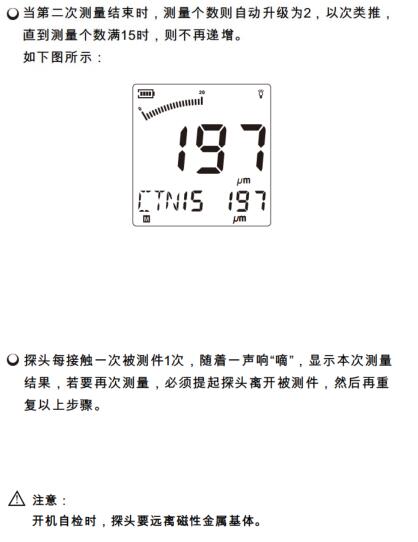

introduce

Biaozhi GM280F split coating Thickness Gauge adopts the magnetic thickness measurement method, which can quickly and accurately measure the thickness of the coating layer on the ferromagnetic metal substrate without damage (such as paint, electrolytic layer, etc.) . It is widely and widely used in manufacturing, metal processing, chemical industry, commodity inspection and other testing fields.

feature or function

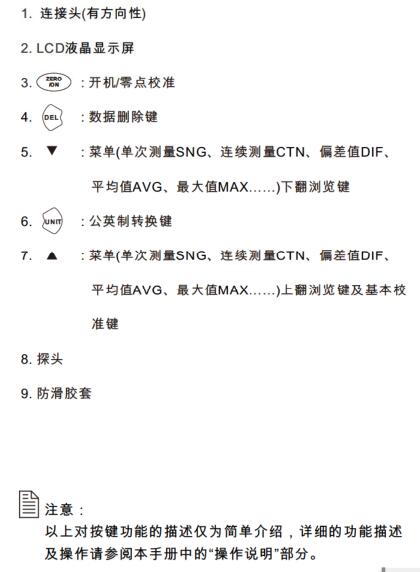

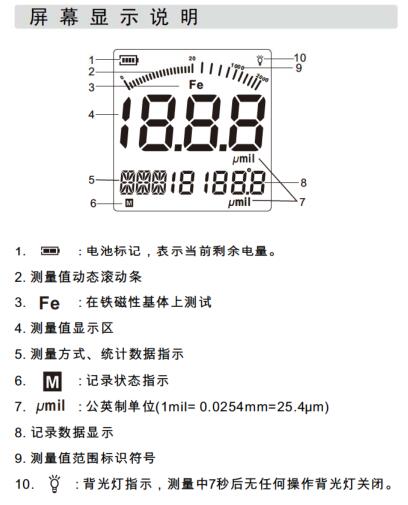

LCD visually displays the measured value and measurement status

Using high-sensitivity probe, accurate measurement

With zero point, two point and basic three calibration methods, system

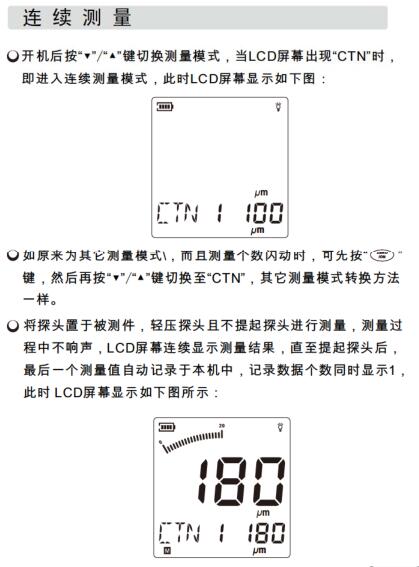

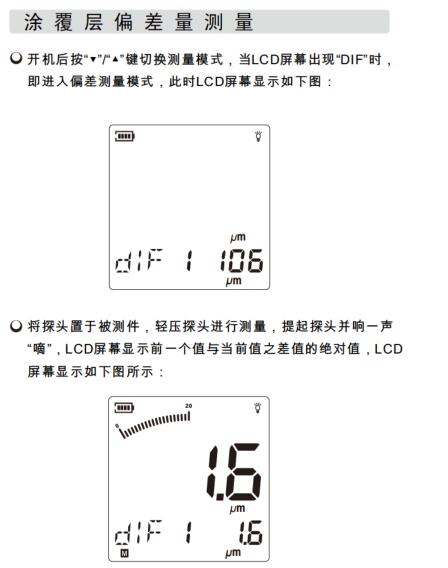

There are three measurement methods of single, injection and deviation

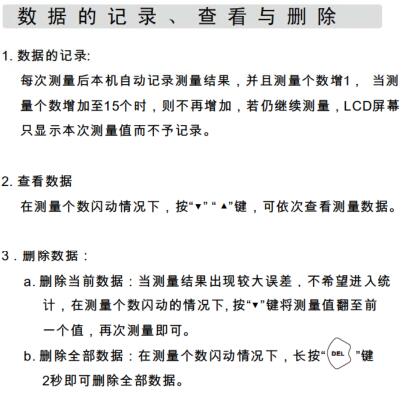

Can record, store, view and delete measurement data

It can delete the single reasonable data that appears in the measurement, and also can erase all the data in the storage area

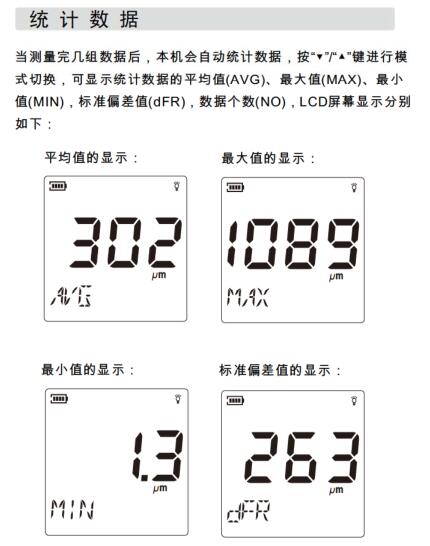

Can count the maximum value, minimum value, average value, standard deviation and measurement times

Buzzer reminder function

Metric and imperial conversion function

Low battery indication function

Auto power off function

LCD backlight function

2. Operating Instructions

Understanding of standard sheets & substrates

Standard sheet:

a. Samples with known thickness can be used as quasi-standard pieces, referred to as standard pieces.

b. Standard sheet with overlay:

The GM280F Split Coating Thickness Gauge uses a known thickness, uniform, and solidly combined coverage layer as a standard piece. For this instrument, the covering layer shall be non-magnetic.

Substrate:

a. The magnetic properties and surface roughness of the standard base metal of this instrument should be similar to the magnetic properties and surface roughness of the base metal of the test piece. In order to confirm the applicability , the readings measured on the standard substrate and the substrate to be tested can be compared.

b. If the thickness of the base metal of the special test piece does not exceed the threshold thickness specified in the parameter table , the following two methods can be used for calibration:

(1). Calibrate on a metal standard sheet with the same thickness as the base metal of the test piece;

(2). Use a metal lining standard sheet or test piece with sufficient thickness and similar electrical or magnetic properties , but it is necessary to make the base metal and the lining metal seamless. (For the test piece with covering layer on the west side, the method of discussion cannot be used.)

c.如果待测覆盖层的曲率已达到不能在平面上校准,则覆益层的标准片的途层厚度,应与试样的涂层厚度相同。

三、其它事项

影响测量精度的因素及有关说明

a.基体金属磁性:

磁性法测厚受基体金属磁性变化的影响(在实际应用中,,低碳钢確性的变化可以认为是要徴的),为了選免热处理及冷加工因表的影响,应使用与被测件基体金属具有相同性质的标准片对使器进行校准,亦可用待涂覆金属进行被准。

b.基体金属厚度

每一种使器都有一个基体金属的临界厚度。大于这个厚度,,测量就不受基体金属厚度的影响。本仪器的临界厚度値见产品规格中的要求。

c.边場效应

本仪器对试件表面形状的测量变敏感。因此在靠近被测件边缘或内转角处进行测量是不可靠的。

d.曲率

被测件的曲率:对测量有影响。这种影响总随着曲率半径的减少明显地增大。

e.表面粗粧度

基体金属和覆差层的表面粗糙程度对测量有影响。粗糙程度增大,影响增大。粗糙表面会引起系统课差和偶然课差,,每次测量时,在不同位置上应增加测量的次数,以克服这种偶然误差。如果基体金属粗糙,还需要在末除覆的粗糙度相类似的基体金属體件上取几个位置校对使器的零点;或用对基体金属没有腐性的溶剂溶解除去覆差层后,再校对使器的零点。

f.磁场

周田各种电气设各所产生的强磁场,会严重地干就確性法测厚工作。

g.附着物质

本仪器对那些妨得测头与覆差层表面紧密接蝕的附着物质織感,因此,需要清除附着物质,进而保证使器探头和被测件表面直接接蝕。

h.探头压力

探头置于被测件上所施加的压力大小会影响测量的法数,,因此本仪器测头用弹養保持一个基本恒定的压力。

i.探头的放置

探头的放置方式:对测量有影响。在测量中,应当使探头与待测试件表面保持垂直。

j.被测件的变形

探头会使软覆盖层被测件变形,着变形过大,将会测出不太可靠的数据。

2.使用仪器日常应当連守的规定:

a.基体金属特性

标准片的基体金属的磁性和表面粗粧度,应当与被测件基体金属的磁性和表面粗鞋度相似。

b.基体金属厚度

检査基体金属厚度是否超过临昇厚度。

c.边缘效应

不应在紧靠试件的突变处,如边缘、洞和内转角等处进行测量。

d.曲率

不应在被测件弯曲表面上测量。

e.读数次数

通常由f仪器的每次读数并不完全相同,因此需要在每一测量面积内取几个读数。覆盖层厚度局部差异,也要求在指定的面积内进行多次测量,表面粗松时更应如此。

f.表面清);言度测量前,应清除表面上的任何附着物质,如生士、油脂及腐性物质等,但不要除去任何覆盖层物质。

3.关于测量结果的说明:a.According to统计学的观点,一次法数是不可靠的。因此任何由本使器显示的测量值都是多次测量的平均值。这多次测量是在几分之一秒的时间内由测头和仪器完成的。

b.为使测量更加准确,可用本仪器在待测点多次测量,并用田除功能对粗大误差进行田除,然后用本仪器的统计功能处理,获取五个统计量:平均値(AVG)、最大值(MAX)、最小值(MIN)、测量次数(NO)、标准信差值(dFR)。

c.接照国际标准,最终的测量结果可以表达为:

CH=A±2D

其中:CH覆l层厚度

A多次测量的平均值(AVG)

D标准信差(dFR)