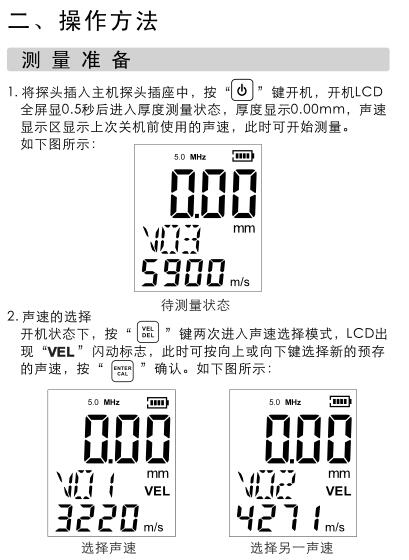

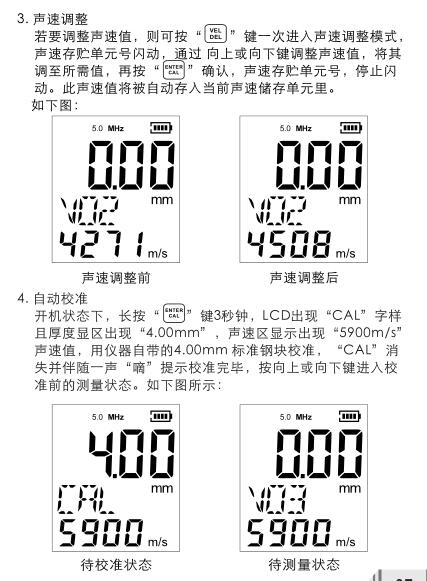

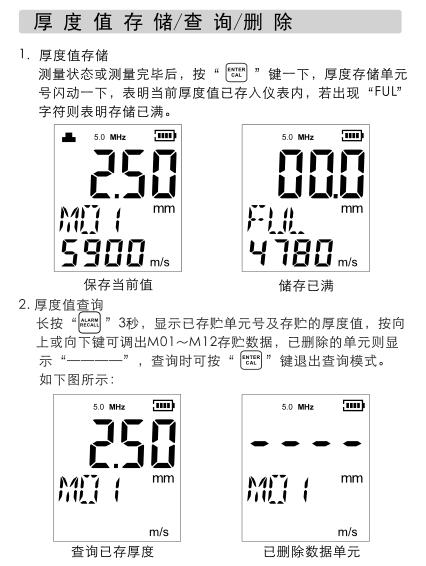

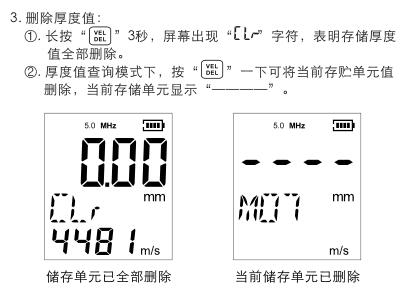

introduce

Biaozhi GM130 Ultrasonic Thickness Gauge adopts the principle of ultrasonic measurement, which is suitable for measuring the thickness of various materials that can make ultrasonic waves propagate inside at a constant speed and can be reflected from the back. This instrument can accurately measure various plates and various processed parts. Another important aspect is that it can monitor various pipelines and pressure vessels in production equipment, and monitor their thinning degree after being corroded during use. Can be widely used in petroleum, chemical industry, metallurgy, shipbuilding, aviation, aerospace and other fields.

2. Basic principles

The principle of ultrasonic measurement of thickness is similar to that of light wave measurement. The ultrasonic pulse emitted by the probe reaches the object under test and propagates in the object, and is reflected back to the probe when it reaches the interface of the material. The thickness of the material under test can be determined by accurately measuring the propagation time of the ultrasonic wave in the material.

3. Scope of application

Metals, plastics, ceramics, glass and any other good conductors of ultrasonic waves, as long as there are two parallel surfaces above and below, can use this instrument to measure thickness, such as steel, aluminum, copper, gold, resin, water, glycerin, etc. Cast iron is not suitable for using this instrument because of its internal crystal grains are too coarse!

4. Main functions

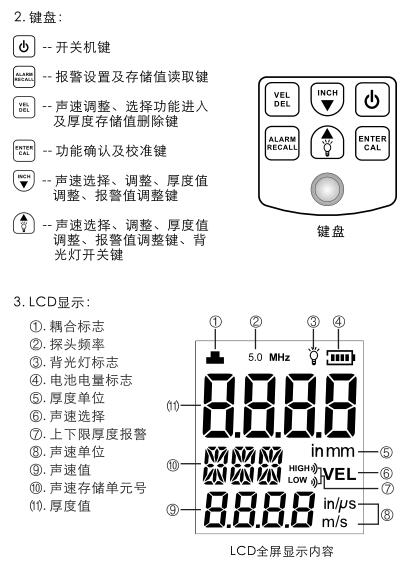

①. System error calibration function.

②.Sound velocity measurement function, which can directly measure the sound velocity according to the actual thickness of the sample block, which can improve the accuracy of thickness measurement.

③. Preset 12 kinds of sound velocity of materials, which can be adjusted and selected for convenient measurement.

④. Coupling status prompt, the coupling status can be known by observing its stable state.

⑤. Can store 12 thickness values, and can query and delete them.

⑥. Upper and lower limit thickness alarm setting function.

⑦.Backlight function.

⑧. Low battery indication function.

⑨.Automatic shutdown, timing automatic shutdown will help you save power.

⑩. Conversion of metric and imperial units.

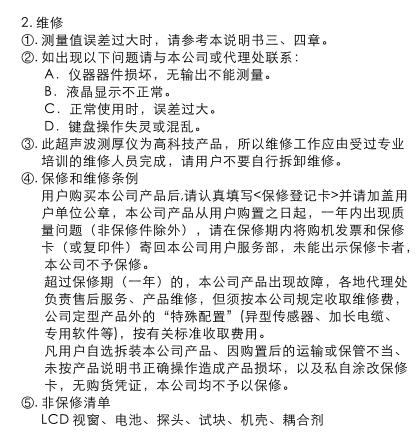

Specifications

1. Measuring range of GM130 ultrasonic thickness gauge: 1.00~300.0mm (steel)

2. Measurement error: ±(1 %H+0.1 mm), H is the real thickness of the measured object

3. Working frequency: 5MHz

4. Measurement resolution: 0.01 mm (1.00~99.99mm)

0.1mm (100~300mm)

5. Pipe measurement lower limit (steel): 15*2.0mm (6 probes)

20*3.0mm (10 probes)

6. Sound velocity measurement range: 1 000~9999m/s

When the thickness of the test block is less than or equal to 20mm, the sound velocity measurement accuracy is ±1%

When the thickness of the test block is ≥20mm, the measurement accuracy of sound velocity is ±5%

7. Working environment: working temperature 0~40℃

Workpiece temperature <60°C

Relative humidity<90%

No strong vibration, no corrosive medium, no collision, humidity, etc.

8. Power supply: three 1.5V AAA alkaline batteries

9. Working current: ≤35mA (power supply: 4.5V with backlight on)

10. Product net weight: 223g

1 1. Product size: 72*29*146mm

3. Measurement technology

1. Clean the surface

Before measurement, all dust, dirt and rust on the surface of the measured object should be removed, and paint and other coverings should be removed .

2. Reduce roughness

Excessively rough surfaces will cause measurement errors, and even the instrument has no reading. Before measurement, try to make the surface of the material to be tested as smooth as possible by using methods such as sanding, grinding, polishing, filing, etc., and high-viscosity couplant can also be used.

3. Rough machined surface:

Regular fine grooves caused by rough machining surfaces (such as lathes or wound beds) will also cause measurement errors. For compensation methods, refer to Item 2 of this chapter; in addition, adjust the probe crosstalk barrier plate (the metal that passes through the center of the probe bottom surface) Thin layer) and the angle (orthogonal or parallel) between the measured material grooves may also achieve better results.

4. Measuring cylindrical surface:

When measuring cylindrical materials, such as pipes, oil drums, etc., the importance of selecting the included angle between the crosstalk barrier plate of the probe and the axis of the material to be tested is self-evident. To put it simply, couple the probe with the material to be tested . The crosstalk barrier plate of the probe is parallel or perpendicular to the axis of the material to be tested. Slowly shake the probe along the direction perpendicular to the axis of the material to be tested. The readings on the screen will change regularly. Choose the minimum value in the readings as the exact thickness .

选择探头串音隔层板与被测材料轴线交角方向的标准取决于材料的曲率,直径较大的管材,选择探头串音隔层板与管子轴线垂直;直径较小的管材,则选择与管子轴线平行和垂直两种测量方法, 取读数中的最小值作为测量厚度。

5.不平行表面:

为了得到一个令人满意的超声响应, 被测材料的另一表面必须与被测面平行或同轴, 否则将引起测量误差或根本无读数显示。

6.材料的温度影响:

材料的厚度与超声波传播速度均受温度的影响, 若对测量精度要求较高时, 可用相同材料的试块在相同温度条件下分别测量,计算出温度对该材料的测量误差,提供参数去校正它,对于钢铁来说,高温将引起较大的误差(测量读数小于实际数据) ,也可用此法来补偿校正。

7.大衰减材料:

对于一些如纤维、多孔、粗粒子材料,它们会造成超声波的大量散射和能量衰减,以致出现反常的读数甚至无读数(通常反常的读数小于实际厚度) ,在这种情况下,则说明该材料不适于用此测厚仪测试。

8.参考试块:

对不同材料在不同条件下进行精准测量, 校准试块的材料越接近于被测材料,测量就越精确。称心的参考试块将是一组被测材料的不同厚度的试块, 试块能提供仪器补偿校正因素(如:材料的微观结构/热处理条件/粒子方向/表面粗糙等)。 为了满足最大精度测量的要求, 一套参考试块将是很重要的。在大部分情况下, 只要使用一个参考试块就能得到令人满意的测量精度, 这个试块应具有与被测材料相同的材质和相近厚度。 取均匀被测材料用千分尺测量后就能作为一个试块。对于薄材料, 在它的厚度接近于探头测量下限时, 可用试块来确定准确的低限。不要测量低于下限厚度的材料。如果一个厚度范围是可以估计的, 那么试块的厚度应选上限值。

当被测材料较厚时,特别是内部结构较为复杂的合金等,应在一组试块中选择一个接近被测材料的, 以便于掌握校准。大部分锻件和铸件的内部结构具有方向性, 在不同的方向上,声速将会有少量变化,为了解决这个问题,试块应具有与被测材料相同方向的内部结构, 声波在试块中的传播方向也要与在被测材料中的方向相同。在一定情况下,查已知材料的声速表,可代替参考块,但这只是近似地代替一些参考试块,在一些情况下,声速表中的数值与实际测量有别, 这是因为材料的物理及化学情况异。这种方法常被用来测低碳钢, 但只能作为粗略测量。本超声测厚仪具有测量声速的功能,故可先测量出声速,再以此声速对工件进行测量。

9.探头串音隔层板磨损对测量造成影响, 出现下列现象时应更换探头:

①.测量不同的厚度时, 其测量值总显示某一值。

②.插上探头不进行测量就有回波指示或有测量值出现。

四、 测量误差的预防方法

1 .超薄材料

使用任何超声波测厚仪, 当被测材料的厚度降到探头使用下限以下时,将导致测量误差,必要时,最小极限厚度可用试块比较法测得。

当测量超薄材料时,有时会发生一种称为“双重折射”的错误结果,它的结果是测得值等于实际厚度的两倍,另一种错误结果被称为“脉冲包络、循环跳跃” ,它的结果是测得值大于实际厚度,为防止这类误差,测临界薄材时应重复测量核对。

2.锈斑、腐蚀凹坑等

被测材料另一表面的锈斑凹坑等将引起读数无规则地变化 ,在极端情况下甚至无读数, 很小的锈点有时是很难发现的。当发现凹坑或感到怀疑时, 这个区域的测量就得十分小心,可选择探头串音隔层板不同角度的定位来作多次测试。

3.材料识别错误

当用一种材料校正了仪器后, 又去测试另一种材料时, 将发生错误的结果, 应注意选择正确的声速。

4.探头的磨损

探头表面为丙烯树脂,长期使用会使粗糙度增高,导致灵敏度下降, 用户在可以确定为此原因造成误差的情况下, 可用500#砂纸或油石少量打磨探头表面使其平滑并保证平行度。如仍不稳定,则需更换探头。

5.自动校准的使用

此功能只能用于将探头耦合在仪器面板上的标准试块上进行校准,而不得在其它任何材料试块上使用,否则将引起测量错误。

6.层迭材料、复合材料

要测量未经耦合的层迭材料是不可能的, 因超声波无法穿透未耦合的空间。 又因超声波不能在复合材料中以匀速传播,所以用超声反射原理测量厚度的仪器均不适于测量层迭材料和复合材料。

7. 金属表面氧化层的影响

有些金属可在其表面产生较致密的氧化层,例如铝,这层氧化层与基体间结合紧密,无明显界面,但超声波在这两种物质中的传播速度是不同的, 故会造成误差, 且氧化层厚度不同误差的大小也不同, 请用户使用时加以注意, 可以在同一批被测材料中选择一块用千分尺或卡尺测量制成样块, 对仪器进行校准。

8.反常的厚度读数

操作者应具备辨别反常读数的能力,通常锈斑、腐蚀凹坑、使用错误的材料或错误的声速校正仪器及被测材料内部缺陷都将引起反常读数。解决方法可参考本说明书第四章第2、3节。

9.耦合剂的使用和选择

耦合剂是用来作为探头与被测材料之间的高频超声能量的传递的。 如果选择种类或使用方法不当将有可能造成误差或耦合标志闪烁,无法测值。耦合剂应适量使用,涂抹均匀。一般来说耦合剂被涂在被测材料的表面。 但当测量温度较高时,耦合剂被涂在探头的底面。选择合适种类的耦合剂是重要的, 当使用在光滑材料表面时,低粘度的耦合剂(如随机配置的耦合剂、轻机油等)是很合适的。当使用在粗糙材料表面,垂直表面及顶面或铝材料时,可使用粘度较高的耦合剂(如甘油膏、润滑脂等)。各种配方的耦合剂各地均有售。 也可向当地代理处购买。

1 0.探头护套

When measuring the curved surface, the curved surface probe sheath is used, which can accurately measure the thickness of the curved surface material . The probe sheath is an optional part and can be purchased from the local agency.