1 Overview

Portable roughness meter is a new generation of pocket portable surface roughness meter launched by our company. It has the characteristics of high measurement accuracy, wide measurement range, easy operation, easy to carry, stable work, etc. It can be widely used in the detection of various metal and non-metal processing surfaces. Hand-held features, more suitable for use in the production site.

※The shape is designed by drawing aluminum mold, which is durable and has remarkable anti-electromagnetic interference ability, which is in line with the new trend of today's design.

※A high-speed DSP processor is used for data processing and calculation, and the measurement and calculation speed are greatly improved.

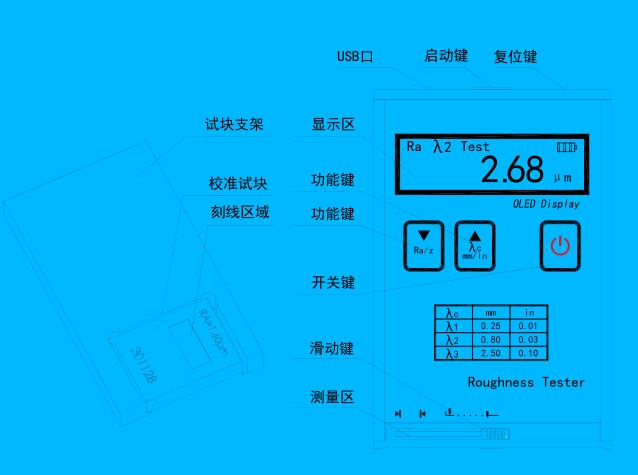

※The display LCD adopts the popular OLED display screen, high brightness, no viewing angle, wide temperature, suitable for various occasions.

※Adopt lithium-ion rechargeable battery, can work for a long time, no memory effect, can work while charging, short charging time, long battery life.

※Use the universal USB interface for charging and communication. Use a dedicated charger or a computer's USB port for charging, which is convenient and quick.

※Dot-matrix liquid crystal display, rich interface prompt information.

※Real-time monitoring and display of lithium battery power, timely remind users to charge and have charging progress prompts.

※Automatic shutdown function and low-power hardware and software design make the instrument work for a long time, suitable for various field use.

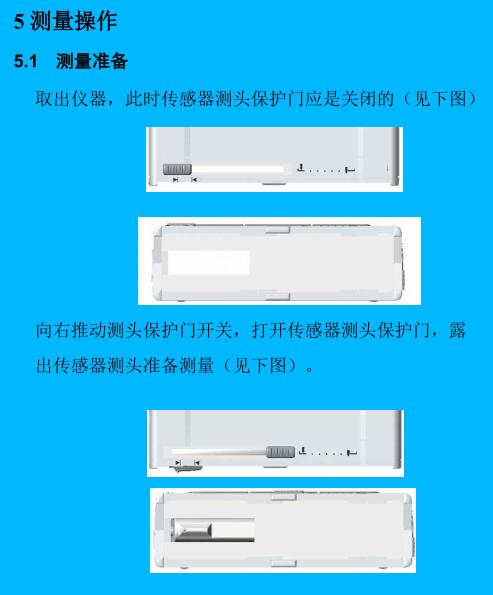

※The sensor probe has a protective door, which effectively protects the sensor probe and ensures the accuracy of measurement.

2 working principle

When the sensor is driven by the driving mechanism to make a uniform linear motion , the internal stylus perpendicular to the working surface produces a vertical displacement with the microscopic uneven contour of the working surface, and then the sensor converts the displacement change into For the change of electric quantity, the electric signal is amplified, filtered, converted into a digital signal by A/D, and then processed by DSP to calculate and display .

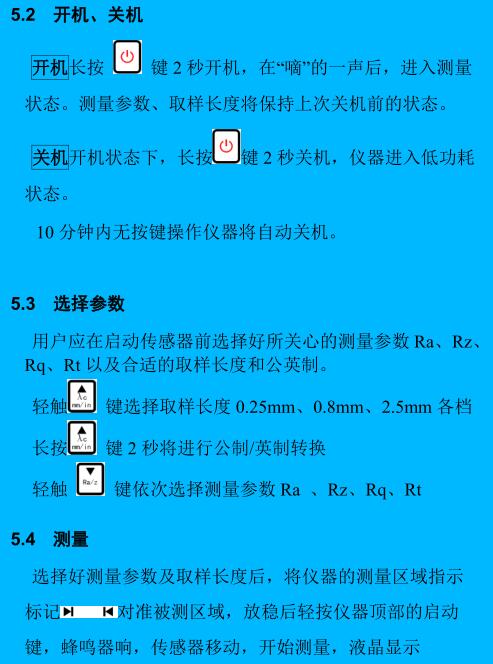

3 Details of the name of each part

6 Daily maintenance and maintenance

6.1 Maintenance

※ Avoid collision, violent vibration, heavy dust, humidity, oil pollution, strong magnetic field, etc .;

※ After each measurement of the roughness of Kaida NDT110 , the power should be turned off in time to maintain the battery energy, and the battery should be charged in time;

※The sensor is a precision part of the instrument, remember to maintain it carefully. After each use , gently cover the protective cover of the instrument. Avoid causing severe vibration to the sensor;

※The random standard template should be carefully protected to avoid scratching and causing the calibration instrument to be inaccurate.

6.2 Maintenance

If the instrument breaks down, the manufacturer is responsible for repairing it. Users are not allowed to disassemble or repair by themselves. The instrument sent back to the manufacturer for maintenance should be accompanied by the calibration sample provided with the warranty card, and the failure phenomenon should be explained.

7. Value definition

The parameter calculation of this instrument complies with GB/T3505 "Terms, Definitions and Parameters of Surface Structure Surface Structure Method of Product Geometric Technical Specification".

※Surface roughness: refers to the micro-geometric shape features composed of small spacing and peaks and valleys on the processed surface.

※Sampling length: It is used to judge the length of a reference line with surface roughness characteristics.

※Assessment length: A length required to evaluate the profile, which can include one or several sampling lengths.

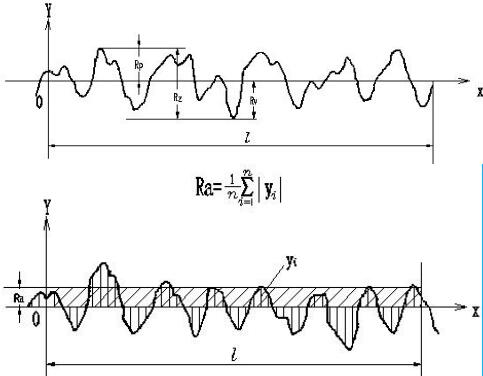

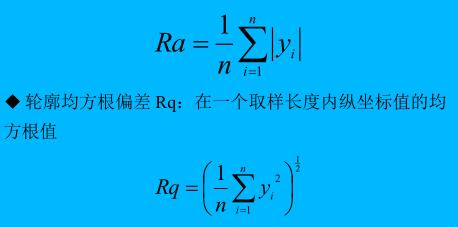

※Contour arithmetic mean deviation Ra: the arithmetic mean value of the contour deviation within the sampling length.

※Profile root mean square deviation Rq: the root mean square value of the ordinate value within a sampling length

※Maximum profile height Rz (ISO): within a sampling length, the height of the sum of the maximum profile peak height Rp and the maximum profile valley depth Rv.

※Total height Rt of profile peak and valley: the sum of maximum profile peak height and maximum profile valley depth within the assessment length.

※The maximum peak height Rp of the profile: the distance from the top line of the profile peak to the midline within the sampling length.

※The maximum valley depth Rv of the profile: the distance from the bottom line of the profile valley to the midline within the sampling length.