Instructions for use

1. Register first, then use; (use manager).

2. Before use, check whether the rotor is installed correctly and whether the locking screw for fixing the rotor is locked.

3. When the centrifuge tube is put into the sample, the capacity of the sample cannot exceed 70%-80% of the capacity of the centrifuge tube. Add the weight of the sample, and the weight error of each group cannot exceed 2 grams. (Check whether the centrifuge tube is broken before loading the sample, if it is broken, it cannot be used any more)

4. Put the centrifuge tube (including the sample) into the adapter and put it into the rotor body (when putting it in, the number of the hanging cup needs to be consistent with the number of the rotor body), and it needs to be placed symmetrically; keep the rotor at high speed. balance.

5. Set the speed, time, temperature, and rotor model;

If the same rotor is used, follow: speed²×time=constant, reduce the speed appropriately, and prolong the time to achieve the same centrifugal effect.

6. If there is sample overflow during centrifugation, please clean the inside of the rotor after centrifugation, and drain the water upside down.

7. For those who use the centrifuge at the end of the day, after centrifugation, take out the rotor from the centrifuge and turn it upside down, wipe the surface of the rotor clean, dry the condensed water in the centrifuge cavity, open the cover door, and turn off the power.

8. Regularly inspect the rotor and observe with the naked eye whether there is any crack on the surface of the rotor body. If there is any crack, please contact the manufacturer in time for proper handling.

9. ELITIST 7K-R large-capacity refrigerated centrifuge is in operation, if abnormal sound is found, it must be shut down in time to eliminate the fault before it can continue to be used.

10. It is recommended that the centrifuge operator use a special person to manage it.

11. In case of a sudden power failure, please use the emergency switch device (place it on both sides of the machine, insert it into the hole with a cross and push it inward to open the door cover), and take out the sample.

Machine rotor model configuration: ("√" in the table indicates the rotor model currently used by this machine)

1 Main purpose and scope of application

ELITIST 7K-R low-speed ultra-large-capacity refrigerated centrifuge is one of the required equipment for biological separation, especially suitable for separation tasks requiring low temperature and high centrifugal force in medical, biological research and routine laboratories.

2 main technical parameters

Maximum speed 7000 r/min

Maximum centrifugal force 10929×g

Maximum capacity 6×2400ml

Temperature range -20℃~40℃

Speed control ±50 r/min

Temperature control ±1.5℃ (‐4℃~25℃)

Timing range 1min~99min

Machine noise ≤68dB(A)

Power supply AC380v 50Hz 30A

Dimensions 1050 × 980 × 940(mm)

Weight 260kg

3 structural features

3.1 The frame-type chassis has high rigidity and beautiful appearance, and has casters for short-distance movement indoors.

3.2 Stainless steel centrifugal chamber, corrosion-resistant, easy to clean, multi-layer safety protection.

3.3 This machine adopts a built-in electronic safety door lock, and a special door lock button is designed. When the instrument is running at high speed, the electronic door lock is closed. Only when the rotation speed is lower than 100 rpm, press the door lock button lightly, and the door cover will automatically open. In case of a sudden power failure during the operation of the machine, in order to ensure that the test samples are taken out, there is an emergency door opening pull ring at the back of the machine. The operator only needs to buckle the pull ring and light it outward, and the door cover can be opened automatically, ensuring the safety of the instrument. Use security.

3.4 The drive system adopts high-precision and long-life bearings, has a broken shaft protection safety device, and a reliable comprehensive anti-vibration and vibration reduction design. The drive adopts a new indirect drive mode high-speed transmission, which can reduce the adverse effects of high-speed motors on centrifugal operation.

3.5 The low back pressure and effective refrigeration compressor is selected, the evaporator is carefully designed and manufactured, and the refrigeration system is carefully adjusted to ensure strong refrigeration and long service life.

3.6 Frequency conversion motor speed regulation, microcomputer control, the set value and real-time value of the centrifugal program parameters are displayed on the LCD screen, and the accumulated running time of the whole machine is automatically memorized, and the integral value of relative centrifugal force (RCF) and centrifugal force time is automatically calculated and displayed.

3.7 Keyboard programming operation, friendly human-computer interaction interface, easy to learn. The LCD screen displays a wealth of operating information in the form of a Chinese dialog box, and the operation is highly transparent.

3.8 Perfect mechanical and electrical safety design, microcomputer control system and inverter control have fault protections such as system overspeed, unbalance, system abnormality, etc., to ensure safe use.

3.9 There are many specifications of suitable rotors to meet the requirements of different users, and continuous flow centrifugal rotors can be equipped according to the order requirements to adapt to large-capacity centrifugal tasks.

3.10 It has a 10-speed step centrifugal function.

4 host installation

4.1 The host should be placed in a room with a flat and rigid floor, avoiding direct sunlight. The distance between the back and the wall is more than 40cm to facilitate the ventilation and heat dissipation of the refrigeration system. There should be more than 30cm of free space on the front and both sides (according to the ISO1010-2 international safety standard) for safety. (External dimensions see attached drawing 1)

4.2 总电源缆线截面不小于6mm2,电源开关电流容量不小于30A,安全接地线应短而粗,连接牢固。并建议用户在实验室出口处另装总电源闸刀开关,以备紧急情况下断开主机供电(按ISO 1010-2国际安全标准)。

4.3 拆除前下罩板,调节左右角两只螺杆支承与地面良好接触,使两前脚轮升起离地,再检查转轴是否呈垂直状态。反复调节与检查,直至符合要求。将前下罩板复位。以后如若移动主机,移动后需要重新调节。

5 转子的安装与使用

5.1 选择本次离心要使用的转子,核对无误。

5.2 清洁转子锥孔面和转轴外锥面,并可涂薄层润滑脂以利使用后取下转子。

5.3 转子装在转轴外锥面上时要对正,用专用工具拧紧压紧螺母,再装锁紧并拧紧;

5.4 建议对转子预冷(安装前将转子在冰箱内预冷,或将转子安装在本机转轴上后启动制冷并以2000r/min低速运转预冷)。

5.5 离心管按公称容量的70%~75%左右加入样品,各离心管加样后总重量的偏差应≤2g。离心管需要对称放入转子。

5.6 如若使用甩平转子,要求吊桶按编号对号入座,要求每个吊桶都得同时使用。如若样品量不够,可在空余的吊桶组以纯净水替代样品对称放入。不允许非对称安装吊桶使用,以防止改变转子应力状态而引起损坏。

5.7 如使用连续流量离心转子,请另见该转子使用说明书。

5.8 各转子都不允许超过额定转速运行。另外,若使用不锈钢离心管或样品比重>1.2g/cm3,都要降速使用。使用不锈钢离心管,一般降至额定转速的80%。样品比重大于1.2时,则按下式重新核定许可的最高转速:

5.9 每次离心前都要检查转子和离心管,严禁使用已腐蚀或有裂纹的转子,严禁使用超过保质期的转子。禁止使用易破损的离心管。

6 使用

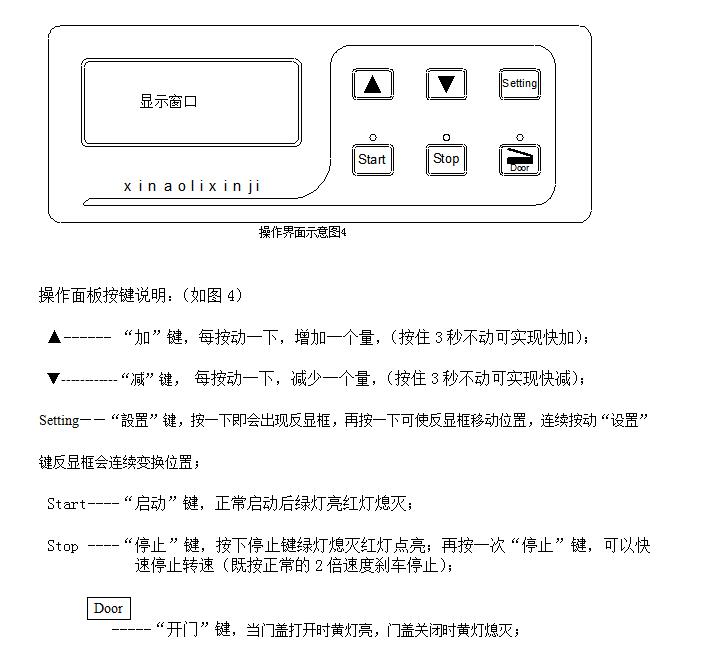

6.1 控制面板和液晶显示屏

熟悉离心机操作和显示请参见控制面板示意图(见附图)

7操作方法:

(特别注意:转子只配有一个,对应转子号只用一个,千万不用随意改变转子号!!)

将电源线接在380V交流电源上(电源功率要求大于30A), 检查无误后打开机器右侧“电源”开关。这时离心机电源接通,压缩机启动;当整机初始化结束后,液晶屏上显示上次设定的“转子号”、“ SPEED转速”、“ RCF离心力”、“ TIME时间” 。等

设定:如对上次的设定需变更,请按以下步骤操作:

设置程序号:

先按动“Setting”(设置)”键,使反显框停留在ROTOr(转子号)上,再按“▲”键或“▼”键,改变程序号。3秒后反显框自动消失(并记忆)。

设置转速:

先按“Setting”(设置)”键,使反显框停留在Speed上;再按“▲”键或“▼”

键,调整转速,按住“▲”键或“▼”键2秒不动即变为快加或快减,当速度显示接近所需值时,再点动“▲”键或“▼”键,使转速符合所需值。

设置离心力:方法同上;可以直接设置离心力,启动离心力;

(注意: ECF:00000xg 有两个功能:(1)在停止状态下,可以作为“离心力”输入窗口;

在运转状态下则作为“离心力”时实显示窗口;)其他参数设置方法同上;

设定完成后,按“STRAT(启动)”键,绿灯亮红灯熄灭,速度显示会自动调速至设定转速(当转速达到设置值后,系统将记忆当前参数设定值,作为下次开机初始值),时间显示将以倒计时方式从设定的时间递减,当时间倒计时剩下最后5秒时,机器发出三声提示音,转头开始降速,直至完全停止。需要特别强调的是:“启动”操作时如果设定的离心时间或设置转速为零,机器将发出操作错误提示音,并禁止启动运行。

机器在运转过程中操作人员可以对“转速”、“时间” 、“离心力”任一参数进行修改。

自编程阶梯离心功能的设定:

PROG:00 为自编程阶梯离心功能的设定;

PROG-------定义为自编程功能;当PROG被反显时,为记忆模式,改变00的值(假如:设为02),等待3秒种后,反显消失;此时,当前所设置的参数被存储在02#存储器中;下一次需要02#参数时,只需将00#反显并调整至02即可。

00------为程序号,当00被反显时(此时为调出程序);共设10个存储号,即:00---09

当存储号为00时,为自由设置离心(只记忆最后一次离心参数);

具体操作方法如下:

1)存入离心参数: 按7.操作方法,设置完成后(例如一:离心力 设为4120g;温度 设为4℃;时间设为10m分钟);按动“Setting”(设置)”键,使反显框停留在PROG上;快速调整“▲”键或“▼”键使PROG:00为PROG:01;放开手不动,3秒种后反显消失,此时所需要的离心参数被存储在PROG:01中;(例如二:离心力 设为2100g;温度 设为22℃;时间设为14m分钟);按动“Setting”(设置)”键,使反显框停留在PROG上;快速调整“▲”键或“▼”键使PROG:00为PROG:02;放开手不动,3秒种后反显消失,此时所需要的离心参数被存储在PROG:02中;

2)调出离心参数: 直接按动“Setting”(设置)”键,使反显框停留在PROG的00#上;快速调整“▲”键或“▼”键使PROG:00为PROG:01;或PROG:02;梢等3秒种,原来的离心参数被调出,可直接启动运行。

3)修改离心参数:如果需要对已经存储的参数进行修改,可进行下列操作:按动“Setting”(设置)”键,使反显框停留在PROG的0X#上,将PROG的0X#调至PROG:00;再按步骤1)操作即可。第2中方法:直接设置您需要的参数,然后将它替换到您认为需要修改的PROG的0X#上。

8.“rate”升/降率的设置在下表中选择:

8其它安全注意事项

8.1 本机无转子自动识别功能,操作者需要确认转子无误。如若输入错误的转子号并且导致相应的许可转速高于转子盖上刻录的最高转速,则因设置错误令转子超速运转,可能发生转子炸裂的恶性事故。

8.2 门盖没关好、离心时间或转速设置为零,机器自动禁止启动。若转子还没停稳,也不能再次启动。

8.3 离心运行时禁止打开门盖,进而保证安全。

8.4 When the automatic control of the machine is abnormal, under normal circumstances, the machine can be restarted and initialized to resume use by clicking the "power" button.

8.5 When the centrifuge is no longer used after centrifugation, press the "power" button to stop the power supply, remove the rotor, and clean the centrifuge chamber. To prevent non-operating personnel from using the machine, the power switch key should be removed. If it is not used for a long period of time, the power switch should be disconnected again, and a desiccant should be placed in the centrifuge chamber to prevent the shaft from rusting.

8.6 This machine has a pre-cooling function. That is, the rotor runs at a low speed of 4000r/min, and at the same time, the temperature is set to -20°C, and the temperature of the centrifuge chamber is reduced to -15°C. After the rotor is pre-cooled, it can quickly cool down to the set temperature during formal centrifugation, so as to better maintain the activity of biological samples.

8.7 The used rotor should be wiped dry with a soft cloth in time and stored in a ventilated and dry place. If biological samples are spilled on the rotor during use, rinse and dry it with pure water in time, especially at the bottom of the hole, to prevent the rotor from being corroded. Practice has proved that the corrosion of aluminum alloy rotors is not completely positively correlated with the pH value of the sample. The corrosion of aluminum rotors by so-called neutral samples (PH7) should not be taken lightly. The rotor should be checked frequently for corrosion (corrosion of aluminum alloys is in the form of spots and gradually increases. Deep pits), it is strictly forbidden to use rotors with corrosion spots and cracks.

8.8 For the continuous centrifuge rotor that is in direct contact with the sample for a long time, please use a titanium alloy rotor with excellent corrosion resistance and higher strength. If the sample contains strong corrosive elements such as sulfur and chlorine, the continuous centrifugal rotor made of aluminum alloy must not be used.

8.9 The rotor bears great alternating stress and centrifugal stress, and its fatigue damage is very common. Therefore, it is generally stipulated in the world that the service life of aluminum alloy rotors is 5-7 years. Aluminum high-speed rotors with a rated speed of more than 10000r/min are forbidden to be used if the shelf life exceeds 7 years, so as to ensure safety. In addition, even if the rotor is within the warranty period, once corrosion and cracks occur, it should be stopped immediately.

8.10 If there is abnormal vibration and noise in the centrifuge, first check whether the load is unbalanced or the shaft is bent, and check whether the machine feet are in good contact with the ground. To replace the main shaft and rotor, you need to contact the original manufacturer. If the speed is out of control or the measurement is wrong, it is necessary to re-check whether the speed measurement and display are correct, and it needs to be repaired by professional technicians or the original manufacturer to prevent safety accidents caused by wrong speed.

Simple faults and solutions