1. Features

*This instrument is a battery-powered portable measuring instrument , which uses the principle of magnetic induction and eddy current. The measurement method conforms to international standards ISO2178, ISO2360 and national standards GB4956, GB4957. It uses computer technology , non-destructive testing technology and other professional technologies to accurately measure the thickness of the measured object without damaging it.

*It can directly measure the thickness of the non-magnetic coating layer (such as : paint, plastic, enamel, copper, aluminum, zinc, chromium, etc. ) on the surface of magnetic conductive materials (such as iron, nickel ). It can be applied to the thickness measurement of electroplating layer, paint layer, enamel layer, aluminum tile, copper tile, babbitt tile, phosphating layer, paper, and also can be used for thickness measurement of hull paint and attachments of underwater structural parts.

*The spring guide sleeve probe with wear-resistant hard metal probe can not only measure on hard or rough surfaces, but also ensure that the probe has constant pressing force and stable sampling value.

*Digital display, wide measuring range and high resolution.

* Automatic memory calibration value, easy to use.

2. Specification

Display: 4-digit 10mm LCD

Lantai CM-8821 coating Thickness Gauge test range: 0~1000 um

Resolution: 0.1um/1um

Measurement accuracy: ±1~3%n or ±2 um

Sampling: single measurement

Power supply: 4 AAA batteries.

Power consumption: about 25 mA

Operating conditions: temperature 0~40°C, humidity <80%

Dimensions: 161×69×32 mm

Weight: 260g (including battery)

appendix:

Carrying case................................1pcs

Probe...................................1pcs

Base block (iron base) ................... 1 piece

Calibration diaphragm

CM50 .................... 1 piece

CM100....................1 piece

CM300....................1 piece

CM500....................1 piece

Instruction manual................................1 copy

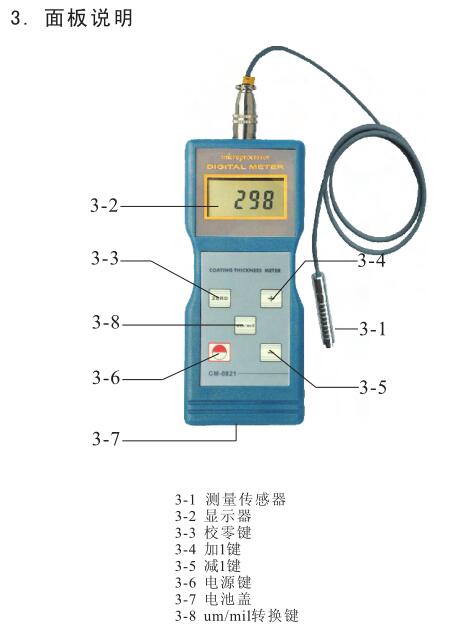

4. measurement procedure

4.1 Press the power button 3-6 lightly, after the whole machine is powered on, the instrument will automatically enter the measurement state .

Note: When the power is turned on, the instrument automatically performs a self-test. In order to ensure the accuracy of the measurement, within 3 seconds when the power is turned on , the measuring probe must not be placed on the iron base, and the probe should not be close to the iron base or other magnetic materials . That is: when the power is turned on, the probe must be kept away from iron base or other magnetic materials.

4.2 After confirming that the calibration is correct, the measurement . If there is any doubt about the previous calibration, another calibration should be performed. The specific method of calibration is detailed in the calibration part of the instrument. Once the instrument is calibrated, the calibration result will be automatically stored in the instrument, and it is not necessary to calibrate again when the instrument is turned on for measurement next time, unless there is doubt about the accuracy of the measurement.

4.3 Pinch the front of the probe about 15mm, press to the coating to be tested, and the value on the display is the measured value of the coating to be tested.

Note: Since all magnetic Thickness Gauges use the principle of electromagnetic induction, it must be noted that the speed at which the probe presses on the object to be measured cannot be too slow. Otherwise, it will cause artificial measurement error.

4.4 For the next measurement, the measurement sensor needs to be lifted above 1 cm, and then repeat 4.3.

4.5 If necessary, the measured value can be corrected by adding 1 key or subtracting 1 key . NBCHAO reminds you: when pressing the plus 1 or minus 1 button to correct , the measuring probe must be lifted, otherwise, pressing the plus or minus 1 button is invalid.

4.6要更换测量单位,实现mm和mil的转换,只要轻按一下单位转换键3-8即可。

5.仪器校准

5.1校零

5.1.1将测量探头压在基准块上(或不带涂层的测量体上),再轻按一下校零键ZERO进行校零。在按ZERO键时,测量探头在基准块上不要晃动。同时要注意,只有在按完ZERO键后,才能提起探头,否则,校零不正确。

5.1.2将测量探头提起1厘米以上,然后再将探头以正常的速度压放到基准块上(或不带涂层的测量体上),观察基准块上同一点的测量值,若测量值在0附近,说明校零成功,否则,应重新校零。

5.2校满度

5.2.1According to要测量的涂层厚度,选择适当的标准膜片,进行满度校准。

5.2.2先将标准膜片放在基准块上(或不带涂层的测量体上)。

5.2.3再将测量探头压在标准膜片上,测量值就显示在显示器上,若测量值与标准膜片不同,测量值可通过加1键或减1键来修正。

5.2.4为保证校满度的准确性,可通过多次测量同一标准膜片来验证。

6.测量注意事项

6.1 为了减少测量体材质对测量精度的影响,建议采用不带涂层的测量体或与测量体材质相同的标准试块作为校准用基准块。

6.2 测量完毕,轻按一下电源键,关断整机电 源。并在测量头的触头及基准块上涂少许油脂以防生锈。

6.3 The instrument has an automatic shutdown function. If there is no operation for about two minutes, it will automatically shut down.

6.4 The instrument should be protected from severe vibration and impact. After use, wipe off the oil on the surface of the instrument and put it in the instrument box for safekeeping.

6.5 It is strictly forbidden to knock or collide with the probe so as not to affect the performance of the probe.

6.6 It is strictly forbidden to pinch the tail of the probe for measurement.

7. Replace the battery

7.1 When the battery voltage is about 5V, the battery symbol will appear on the display, and the battery needs to be replaced.

7.2 Open the battery cover and take out the battery.

7.3 Install the battery correctly according to the label on the battery box.

7.4 If the meter will not be used for a long time, please take out the battery to prevent the battery from rot and damage the meter. Install the batteries correctly as indicated on the label on the battery compartment.