1. Features

* Lantai CM-8822 Coating Thickness Gauge is a battery-powered portable measuring instrument , which adopts the principle of magnetic induction and eddy current. The measurement method conforms to international standards ISO2178, ISO2360 and national standards GB4956, GB4957. It uses computer technology , non-destructive testing technology and other professional technologies to accurately measure the thickness of the measured object without damaging it.

*It can directly measure the thickness of the non-magnetic coating layer (such as : paint, plastic, enamel, copper, aluminum, zinc, chromium, etc. ) on the surface of magnetic conductive materials (such as iron, nickel ). It can be applied to the thickness measurement of electroplating layer, paint layer, enamel layer, aluminum tile, copper tile, babbitt tile, phosphating layer, paper, and also can be used for thickness measurement of hull paint and attachments of underwater structural parts.

* It can also measure the thickness of the insulating coating on the non-magnetic metal substrate , such as paint, plastic, rubber coating on the surface of aluminum, copper, zinc, non-magnetic stainless steel and other materials , and can also measure the anode of aluminum or aluminum alloy materials oxide layer thickness.

*The spring guide sleeve probe with wear-resistant hard metal probe can not only measure on hard or rough surfaces, but also ensure that the probe has constant pressing force and stable sampling value.

*Digital display, wide measuring range and high resolution.

* Automatic memory calibration value, easy to use.

* Lantai CM-8822 Coating Thickness Gauge is sturdy, delicate and easy to carry.

2. Specification

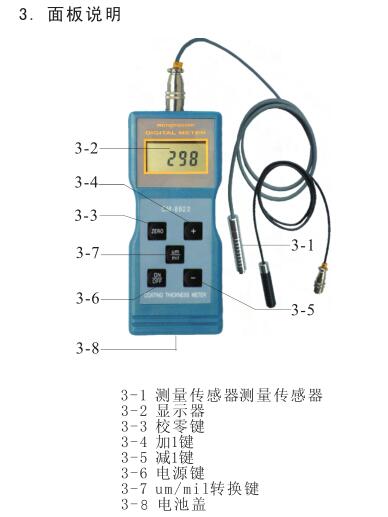

4. measurement procedure

4.1 Select the corresponding measuring probe according to the measured object. The instrument can automatically identify the type of probe.

4.2轻按电源键3-6,接通整机电源后,仪器自动进入测量状态。

注意:在打开电源时,本仪器自动进行自检。为确保测量的准确性,打开电源时的3秒钟内,一定不要将测量探头放在铁基上,也不要将探头靠近铁基或其他磁性材料。即:在打开电源时,探头一定要远离铁基或其他磁性材料。

4.3在确认校准正确的前提下,就可开始测量。若对以前的校准有所怀疑的话,应再进行一次校准。校准的具体方法详见仪器的校准部分。仪器一旦校准,校准结果将自动存贮在仪器中,下次开机测量时,可不必再次进行校准,除非对测量的准确性有怀疑。

4.4将测量传感器压紧到被测涂层上,显示器上的值即为待测涂层的测量值。

注意:由于所有磁性测厚仪都是采用电磁感应原理,因此,一定要注意探头压上被测体的速度不能太慢。否则,会造成人为测量误差。

4.5要进行下次测量,需要将测量传感器提起到1厘米以上,然后再重复4.3。

4.6如有必要,测量值可通过加1键或减1键来修正。南北潮提示您:按加1键或减1键修正时,测量探头一定提起,否则,按加1键或减1键无效。

5.仪器校准

5.1校零

5.1.1将测量探头压在基准块上(或不带涂层的测量体上),再轻按一下校零键ZERO进行校零。在按ZERO键时,测量探头在基准块上不要晃动。同时要注意,只有在按完ZERO键后,才能提起探头,否则,校零不正确。

5.1.2将测量探头提起1厘米以上,然后再将探头以正常的速度压放到基准块上(或不带涂层的测量体上),观察基准块上同一点的测量值,若测量值在0附近,说明校零成功,否则,应重新校零。

5.2校满度

5.2.1According to要测量的涂层厚度,选择适当的标准膜片,进行满度校准。

5.2.2先将标准膜片放在基准块上(或不带涂层的测量体上)。

5.2.3再将测量探头压在标准膜片上,测量值就显示在显示器上,若测量值与标准膜片不同,测量值可通过加1键或减1键来修正。

5.2.4为保证校满度的准确性,可通过多次测量同一标准膜片来验证。

6.测量注意事项

6.1基准块的选择原则基准块的选择要与所选择的探头一致。 当选择铁基探头时, 基准块要用铁基; 当选择非铁基探头时, 基准块要用铝基。

6.2 为了减少测量体材质对测量精度的影响,建议采用不带涂层的测量体或与测量体材质相同的标准试块作为校准用基准块。

6.3 After the measurement is completed, press the power button lightly to turn off the power of the whole machine. And apply a little to prevent rust.

6.4 The instrument has an automatic shutdown function. If there is no operation for about two minutes, it will automatically shut down.

6.5 The instrument should be protected from severe vibration and impact. After use, wipe off the oil on the surface of the instrument and put it in the instrument box for safekeeping.

6.6 It is strictly forbidden to knock or collide with the probe so as not to affect the performance of the probe.

7. Replace the battery

7.1 When the battery voltage is about 5V, the battery symbol will appear on the display, and the battery needs to be replaced.

7.2 Open the battery cover and take out the battery.

7.3 Install the battery correctly according to the label on the battery box.

7.4 If the meter will not be used for a long time, please take out the battery to prevent the battery from rot and damage the meter. Install the batteries correctly as indicated on the label on the battery compartment.