1. Characteristics

* Coating film hardness is a must-test index . This instrument applies the pencil scratch method to determine the film hardness of an organic coating on a substrate in a quick and economical manner by means of a drawing lead or pencil lead of known hardness . The pencil scratch method to test the hardness of the coating film has been widely used in the world since the 1980s . Our country has also promoted this test method in the development research and industrial production of coatings. The instrument can be used both in the laboratory and on the construction site.

* Reference standards: "GB/T 6739-96" Pencil Test Method for Hardness of Coating Film "ASTM D3363-00" Standard Test Method for Determination of Hardness of Coating Film by Pencil Test Method "GB/T 1727-92" General Preparation Method of Paint Film

2. Specifications and principles

Load weight: 1000g /750g /500g

The angle between the pencil and the surface to be tested: 45°

Three-point contact with the surface to be tested (two rollers, pencil lead)

Scratch speed: about 1mm/s

Standard configuration:

Pencil Hardness Tester... 1 set

1000g weight........ 1

750g weight........ 1

A set of pencils (6B-6H)....... 13 pieces

Eraser.................... 1 piece

Pencil sharpener.................. 1 piece

Horizontal spacer........ 1 piece

No.400 sandpaper......... 1 sheet

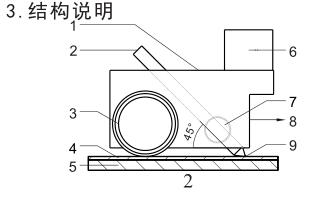

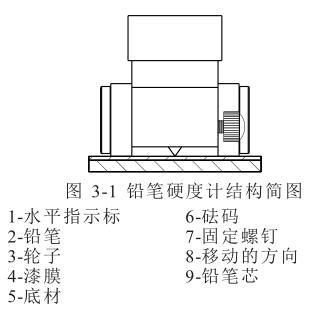

Lantai HT-6510P Pencil Hardness Tester is a mechanical type, three points contact the surface (two points are the wheel, one point is the lead), always ensure that the pencil and the test surface form an angle of 45°, push the instrument to slide by hand, the pencil will Draw the corresponding track on the paint film . Use different pencils to draw different marks, based on which the hardness .

4. Measurement procedure

4.1 Test plate regulations

Unless there is a customer request or otherwise agreed, the test sample is the finished product of the coating process; when the width or length of the product coating is less than 1cm, a test sample needs to be made , and the size of the sample is 50x120 mm or 70x150 mm. The product process remains completely consistent.

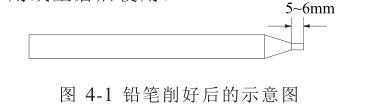

4.2 Provisions for the pencil used in the test Use a pencil sharpener to cut off the wooden part, so that the pen core is expose about 5~6mm, and the pen core must not be loosened or scratched. Then place No.400 sandpaper on a hard surface , place the pen refill vertically against the sandpaper to draw circles, and grind until the tip of the pen is ground into a plane and the edge is sharp, and the edge must not be broken or notched . (Pencil should be rotated 180° after or re-sharpened)

4.3 Test steps

4.3.1 Place the horizontal block under the instrument body. Take out the pencils prepared with corresponding specifications ( starting from the hardest lead), and insert them obliquely into the holes inclined at 45 degrees on the detection trolley. The extension length of the pencil core is just in contact with the surface of the sample to be tested, and the fixing screw is tightened so that the pencil cannot be loosened. (According to the testing requirements of the test product, choose whether to add weight)

4.3.2 取出水平垫块,观察水平指示标,保证气泡在两条标志线之间,若气泡不在两条标志线之间,则重新调节,使气泡处于两条标志线之间,再进行测量。用1mm/s的速度向前推进,铅笔在被测面上划出一道线。松开固定螺钉,铅笔旋转180°或重新研磨,再划一道线。依次操作,在样品可视区不同位置划线5次,建议笔线长度为6.5 mm,划线完毕用橡皮擦擦拭被测品后检查外观及功能。

4.3.3 涂膜刮破的情况:5次中若有两次能犁破涂层则换用较软的铅笔一支,直至找出5次中至少有4次不能犁破涂层的铅笔为止,此铅笔的硬度即为被测涂层的铅笔硬度。

5. 注意事项

* 在削铅笔时需要注意,所削出的笔芯形状需要为圆柱体。

* 在装入铅笔时需要用平衡垫块垫在小车的前端下部,以免装入的铅笔存在角度差。

* 在推动小推车的过程中,用力不可过猛,以能够推动小车前行为宜,以免压断笔芯。

* 每向前推动测试一次需要松开固定螺钉,扭动铅笔,更换铅笔角度再固定好测试。

* Pencil selection during the test: follow the measurement sequence of 6H-5H- 4H-3H-2H-HF-HB-B-2B-3B-4B- 5B-6B in decreasing hardness. Start the test according to the first standard, gradually replace the softer pencil, and obtain the final test data.

* Before using the instrument, inspect the appearance and function to ensure that the test sample functions normally, the appearance is free from damage, cracks, scratches, etc., and the surface is smooth and flat .

* It is recommended to use this instrument with gloves to avoid rusting of the instrument .