Instructions for use

1. Register first, then use; (use manager).

2. Before use, check whether the rotor is installed correctly and whether the locking screw for fixing the rotor is locked.

3. When the centrifuge tube is put into the sample, the capacity of the sample cannot exceed 70%-80% of the capacity of the centrifuge tube. Add the weight of the sample, and the weight error of each group cannot exceed 2 grams. (Check whether the centrifuge tube is broken before loading the sample, if it is broken, it cannot be used any more)

4. The centrifuge tube (containing the sample) is put into the adapter and put into the rotor body, and it needs to be placed symmetrically; keep the balance of the rotor when it is running at high speed.

5. Before starting, please set the speed, time and rotor type;

If the same rotor is used, follow: speed²×time=constant, reduce the speed appropriately, and prolong the time to achieve the same centrifugal effect.

6. If there is sample overflow during centrifugation, please clean the cavity of the centrifuge after centrifugation.

7. For those who use the centrifuge at the end of the day, after centrifugation, wipe the surface of the rotor clean and turn off the power.

8. Regularly inspect the rotor and observe with the naked eye whether there is any crack on the surface of the rotor body. If there is any crack, please contact the manufacturer in time for proper handling.

9. During the operation of the centrifuge, if any abnormal sound is found, it must be shut down in time to eliminate the fault before it can continue to be used.

10. Opening the door: When the machine is stopped and running, press the door open button to open the door; if the door needs to be opened during a power failure, there is a nylon rope at the bottom of the machine, pull it hard, and the door can be opened.

1 Main purpose and scope of application

GENIUS 6K-C desktop low-speed automatic balancing centrifuge can perform primary separation, concentration and purification of emulsions, suspensions and other samples. It can be used for the separation of biological cells, lymph fluid and enzymes, and is widely used in basic research fields such as clinical medicine, biochemistry and immunology. It is one of the commonly used equipment required by laboratories and departments such as biochemical and pharmaceutical industries.

2 main technical parameters

Maximum speed:6,000 r/min

Maximum centrifugal force:5,241×g (g is the acceleration of gravity)

Machine noise:≤58dB

Working speed range:100~6000 r/min

Speed setting fineness:100r/min

Speed control accuracy:±50r/min

Timing setting range:0~9 hours 59 minutes

Time setting fineness:1 minute

Timing Control Accuracy:±1%

Maximum separation capacity:32×15ml

power supply: AC220V50Hz

Ambient temperature:Room temperature +5℃~40℃

Dimensions:540mm×450mm×370mm

Weight: 42Kg

3 structural features

This machine is composed of frame, centrifugal chamber, drive system, control system, rotor, etc., and is directly driven by high-performance variable frequency motor; rubber spring damping and two-stage shock absorber damping and shock absorption, the noise of the whole machine is 5-10dB lower than similar models . The speed and time are controlled by a full digital microcomputer, which can directly set the centrifugal force to start the rotor operation, and can automatically memorize the operating parameters used by the user. When the keyboard is operated, the LCD screen above the keys displays the working status throughout the process. The large LCD screen with backlight can further ensure that the display results can be clearly observed from a long distance when in use. The operation interface is friendly, and the user feels very simple and clear when operating.

A complete set of complete machine abnormal or fault alarm protection functions such as overspeed protection, speed measurement protection, and operation error alarm are added to the design. During the operation of the machine, when there are situations such as "exceeding the rated speed", "the time is up", "when the speed drops to zero" and "the machine has abnormal speed", the buzzer will emit a "beep-beep" sound, (At the same time, the fault information is displayed in the fault area) to remind the operator to pay attention in order to deal with it in time.

After the centrifugation parameter setting is completed correctly, turn off the "power", and the program will store the centrifugation parameters into the memory chip. In the future, the centrifugation operation will be as simple as pressing the "START" button lightly each time, even if the machine is powered off and restarted (automatically memorizes the parameters of the last centrifugation).

To sum up, this model has the characteristics of easy operation, low noise, high measurement and control accuracy, simple maintenance, high reliability, good safety, long service life, user-customizable operation control functions, and software upgrades. The comprehensive performance index of the machine has reached the international professional level.

4 host installation

● The machine should be placed on a solid workbench. The working environment should be dry and clean. The height of the work table is preferably about 0.65m. The back of the machine should be no less than 10cm away from the wall to facilitate heat dissipation of the machine.

● When installing the rotor, please apply a little lubricating grease on the conical surface of the rotating shaft to protect the rotating shaft from rust due to pollution and moisture, and to make the rotor easy to assemble and disassemble. After the rotor is installed on the rotating shaft, press it with the locking screw. When turning the locking screw with a wrench, use appropriate force and do not use excessive force to avoid damage to the locking screw.

● When the centrifuge tubes are loaded into the tube rack, they need to be placed symmetrically, and the sample volume in each centrifuge tube should be equal.

5. Instructions before use

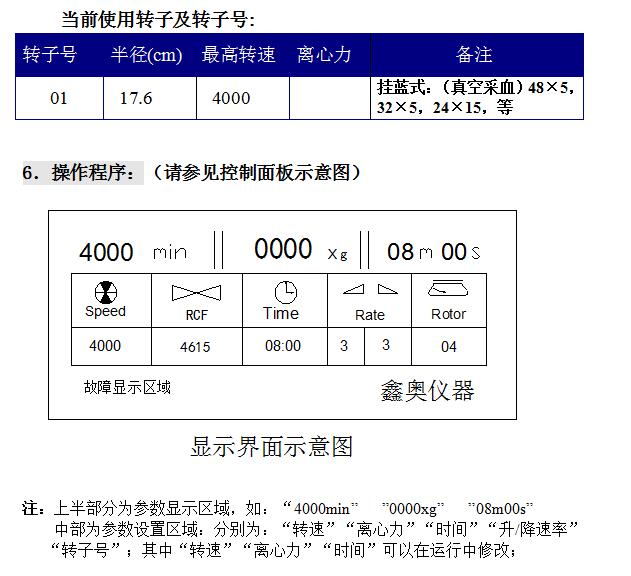

Pay attention to check the rotor number before use, the set rotor number must be the same as the actual rotor number; the centrifugal force corresponding to different rotor numbers is different.

The following table is the configuration table of all the rotors of this machine. Mark "√" in the table to indicate the current rotor used by this machine and the rotor number that should be set;

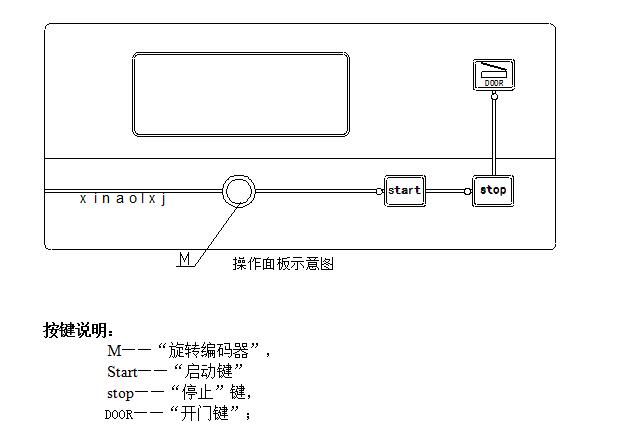

7Operation method:

将电源线在220V交流电源上(电源功率要求大于20A), 打开机器右侧“电源”开关。这时离心机电源接通,当整机初始化结束后,液晶屏上显示上次设定的“转子号”、“转速SPEED”、“离心力RCF”、“时间TIME”。等

设定:如对上次的设定需变更,请按以下步骤操作:

设置程序号:先按“Setting”(设置)”键,使反显框停留在ROTOr上,再按“▲”键或“▼”键,改变程序号。3秒后反显框自动消失。

设置转速:先按“Setting”(设置)”键,使反显框停留在Speed上;再按“▲”键或“▼”键,调整转速,按住“▲”键或“▼”键2秒不动即变为快加或快减,当速度显示接近所需值时,再点动“▲”键或“▼”键,使转速符合所需值。

设置离心力:方法同上;可以直接设置离心力,启动离心力;注意: ECF:00000xg 有两个功能:(1)在停止状态下,可以作为“离心力”输入窗口;在运转状态下则作为“离心力”时实显示窗口;

其他参数设置方法同上;

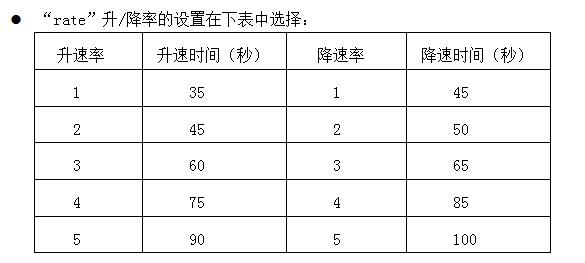

设定完成后,按“STRAT(启动)”键,绿灯亮红灯熄灭,速度显示会自动调速至设定转速(当转速达到设置值后,系统将记忆当前参数设定值,作为下次开机初始值),时间显示将以倒计时方式从设定的时间递减,当时间倒计时剩下最后5秒时,机器发出三声提示音,转头开始降速,直至完全停止。需要特别强调的是:“启动”操作时如果设定的离心时间或设置转速为零,机器将发出操作错误提示音,并禁止启动运行。

机器在运转过程中操作人员可以对“转速”、“时间” 、“离心力”任一参数进行修改

小提示:(本机采用了新的的软启动方式:即:开机3秒后,屏幕显示所有参数;关机5秒后显示屏熄灭;)

当一次离心完成后,待转子转速低于100转以下,电子门锁解锁,才能打开门盖(注意:在转子运转中,请不要使用应急开门系统,以免发生意外事故),取出样品,如果不需进行下次离心,请关闭“电源”,机器停止所有运行,拔下

电源插头,取下转头,并将转子清洗擦净晾干待用。再将离心室内擦净吹干。

如果用户将较长一段时间不使用机器,请务必将电源配电板上的闸刀开关断开或将电源线插头从电源插座上拔下。

机器异常与恢复:当机器出现操作使用异常时,一般情况下可通过关闭 “电源”开关,使机器关机再重新开机初始化即可恢复使用。

8. 有下列情形之一,不允许启动

● 转子安放没有用锁紧杆锁紧。

● 转子负荷不对称、不平衡(离心管装的样品重量差异大,离心管不对称放置)。

● 预选转速超过转子的最高使用转速。

● 门盖未盖好。

● 转子出现腐蚀,裂纹或已超过转子保质期时。

● 电源电压过高或过低,超过标准的70%以上时。

● 因为该机型没有配置制冷系统,所在离心过程中离心腔内的温度会逐渐升高,为了不损坏您的分析样品,请您设定一个警告温度,如果设定的警告温度低于离心腔内实际温度,则温度保护,机器自动停止运行。

9.维护保养及注意事项

● 机器应安放在干燥、清洁的地方,潮湿及灰尘将损害机器,缩短机器的使用时间。

● 每天离心工作完成后,应将转子取下,清洁后通风干燥,并避免与硬物或尖锐物件碰撞而划伤转子体。因离心室内容易集结潮气,转轴上平时要抹上一层润滑脂防潮,机器平时不用时,更好将门盖打开,以散发离心室内的潮气。

● 离心管破裂或有分离液落入试管套和风罩中,需要及时清洗擦干,特别是试管套底部。

● 定期检查转子有无腐蚀点、细小裂纹,使用前检查更为必要,进而保证使用安全。

● 离心机在运转过程中如出现异常振动和噪音,表明转子负载不对称或试液重量偏大,此时应立即停机,并检查转子的负载情况,看是否对称及试液有否重量偏差过大。如仍不正常,需请专业技术人员检查。

10. 转子的维护保养及使用寿命

● 定期检查转子和离心管的内、外表面氧化层,若有剥落腐蚀或严重划伤、裂纹,应停止使用

● 每天离心工作完成后,用干净的软布擦去离心室、风罩和试管套内、外表面的残留液和水分,晾干待用。

● 使用转子、离心杯时,应防止相互碰撞损伤。

● 暂时不用的转子、离心管,应从离心室取出存放在清洁干燥处。

● The working life of the rotor is limited. The various rotors used in this machine have a working life of five years (that is, the shelf life of the rotor is five years) under the condition that the usage and maintenance requirements of the rotors are strictly followed. The shelf life of the rotor starts from the date of delivery. When the rotor is corroded, it will produce corrosion spots and fine cracks. The combined action of corrosion and centrifugal force will greatly weaken the strength of the rotor and shorten the life of the rotor. If the rotor is operated at a speed far below the allowable maximum speed, the rotor will also be damaged. Therefore , It is strictly forbidden to use corroded and cracked rotors. The shelf life of rotors does not apply to rotors that have developed corrosion and cracks.

● If the rotor or test tube cover is damaged due to corrosion or other reasons, stop using it immediately, and contact the manufacturer in time to conduct necessary safety inspection and appraisal to confirm whether it needs to be repaired or updated. For users caused by corrosion or improper use If the rotor and test tube cover are damaged, the responsibility shall be borne by the user.

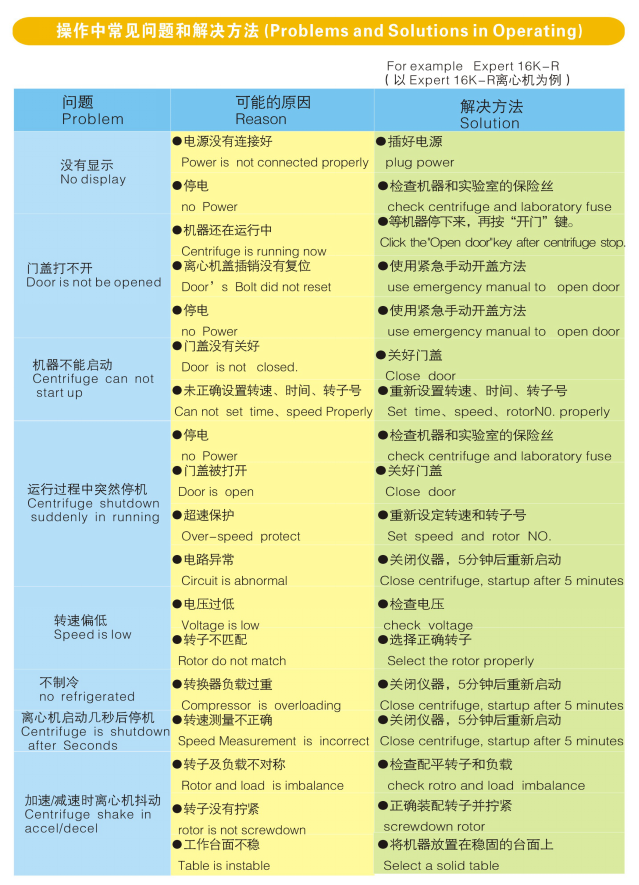

Simple faults and solutions