Instructions for use

1. Register first, then use; (use manager).

2. Before use, check whether the rotor is installed correctly and whether the locking screw for fixing the rotor is locked.

3. When the centrifuge tube is put into the sample, the capacity of the sample cannot exceed 70%-80% of the capacity of the centrifuge tube. Add the weight of the sample, and the weight error of each group cannot exceed 2 grams. (Check whether the centrifuge tube is broken before loading the sample, if it is broken, it cannot be used any more)

4. The centrifuge tube (containing the sample) is put into the rotor body and needs to be placed symmetrically; keep the balance of the rotor when it is running at high speed.

5. Set the speed, time, temperature, and rotor model;

If the same rotor is used, follow: speed²×time=constant, reduce the speed appropriately, and prolong the time to achieve the same centrifugal effect.

6. If there is sample overflow during centrifugation, please clean the inside of the rotor after centrifugation, and drain the water upside down;

7. For those who use the centrifuge at the end of the day, after centrifugation, take out the rotor from the centrifuge and turn it upside down, wipe the surface of the rotor clean, dry the condensed water in the centrifuge cavity, open the cover door, and turn off the power.

8. Regularly inspect the rotor and observe with the naked eye whether there is any crack on the surface of the rotor body. If there is any crack, please contact the manufacturer in time for proper handling.

9. During the operation of the centrifuge, if any abnormal sound is found, it must be shut down in time to eliminate the fault before it can continue to be used.

10. It is recommended that the centrifuge operator use a special person to manage it.

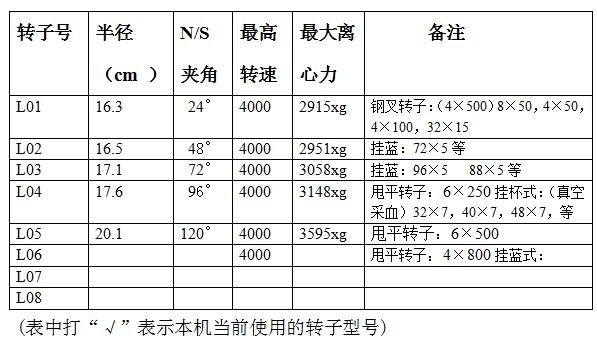

Please pay attention when using: the marking on the rotor head indicates that the corresponding rotor program number and rotor radius should be set in strict accordance with the model:

1 Main purpose and scope of application

ELITIST5K-R vertical high-speed large-capacity refrigerated centrifuge can separate, concentrate and purify emulsion and suspension samples. It can be used for separation of biological cells, lymph fluid and enzymes, high-density protein and white blood cell tests, purification of ribonucleic acid and DNA, and is widely used in basic research fields such as clinical medicine, biochemistry and immunology. It is one of the commonly used equipment required by laboratories and departments such as biochemical and pharmaceutical industries.

2 main technical parameters

Maximum speed: 4000r/min

Maximum centrifugal force: 3595×g(g is the acceleration due to gravity)

Working speed range: 300 r/min ~ 4200 r/min

Speed control accuracy: ±50r/min

range of working temperature:-20℃~+40℃

Temperature control accuracy: ±1°C

Timing range: 99 minutes

Machine noise: ≤65db (A)

power supply: AC220V±10% 50Hz±2% 16A

Dimensions: Length 790mm × Width 620mm × Height 800mm

weight: 140kg

3 structural features

※This instrument is composed of frame, centrifuge chamber, drive system, refrigeration system, control system, rotor, etc. It is directly driven by high-performance, ultra-low noise frequency converter and frequency conversion high-speed motor, with two-stage damping and shock absorption, and low noise. Refrigeration adopts a fully enclosed low-temperature compressor. The speed, temperature and time are controlled by a fully digital microcomputer, and can automatically remember the operating parameters of the last operation.

※The display window of this instrument adopts a large-screen LCD screen, which can display various technical parameters of the current instrument operation. The light-touch keyboard is operated, and the operation interface is friendly. The user feels simple and clear when operating.

※ This instrument adopts a built-in safe electric automatic door lock, and is equipped with a special door lock keyboard. The instrument is in a self-locking state during operation. When the running speed is lower than 100 rpm, press the door lock button, and the door cover will automatically open. Ensure the safety of the instrument in operation.

※ When the instrument is running, there is a sudden power failure. In order to ensure that the samples are taken out in time, the machine is designed with a special emergency opening hole. will be turned on automatically).

※The design of this instrument complies with IEC1010-1 and IEC1010-2 international safety standards.

※The speed measurement and control adopts Hall digital sensor to measure speed; the temperature measurement adopts a special temperature sensor, and the software linear compensation corrects the accuracy to obtain the measurement and control temperature data after digital sampling by the microcomputer, and controls the opening and closing of the solenoid valve of the refrigeration system to realize temperature control; the centrifugal timer adopts quartz crystal The oscillator is the time reference, and they are respectively controlled by the seamless interface with the system microcomputer. It is equipped with high-precision digital "speedometer", "thermometer" and "quartz clock". The measurement and control do not need to be debugged and calibrated, and the measurement and control accuracy and linearity are guaranteed.

※In the design, a complete set of complete machine abnormality or fault alarm protection functions are added, such as overspeed protection, speed measurement protection, and operation error alarm. During the operation of the machine, when there are situations such as "incorrect operation", "time out", "speed down to zero" and "abnormal speed of the machine", the speakers will emit their own unique prompt sounds to remind the operator to pay attention , for timely processing.

To sum up, this model has the characteristics of easy operation, low noise, high measurement and control accuracy, simple maintenance, high reliability, good safety, long service life, user-customizable operation control functions, and software upgrades.

4 installation

※The machine should be placed on a solid ground and adjusted to a good level.

※转子在安装时,请在转轴的锥面抹少许润滑脂。以保护转轴不易受潮生锈、并使转子装卸容易。转子装在转轴上后,用随机配送的专用扳手旋动锁紧螺杆紧固转子。

※离心管装入转头中时,需要对称放置,(微量离心管装样品时目测平衡即可)。

※电源应为220V单相电源,并具有独立地线,不允许用零线代替地线。

※机器工作环境:应无其它强烈振源,强磁场,腐蚀性气体;相对湿度不大于85‰。

※机器后背距离墙面应大于10公分,进而保证空气流通及良好散热。

五 、 操作与使用

六操作方法:

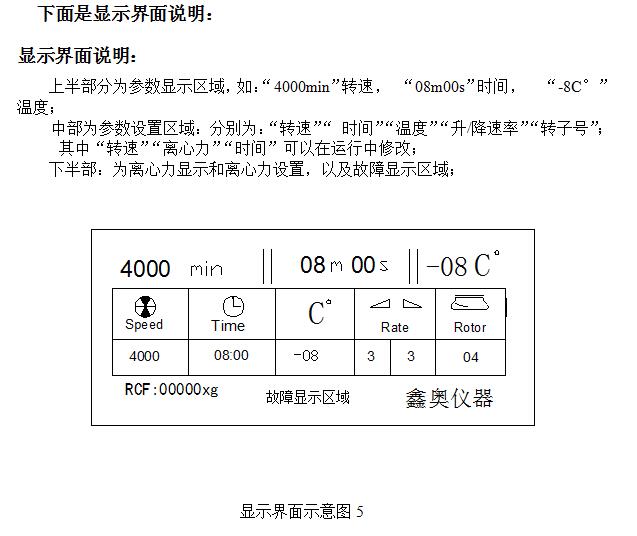

将电源线在220V交流电源上(电源功率要求大于20A), 打开机器右侧“电源”开关。这时离心机电源接通,当整机初始化结束后,液晶屏上显示上次设定的“转子号”、“转速SPEED”、“离心力RCF”、“时间TIME”。等

设定:如对上次的设定需变更,请按以下步骤操作:

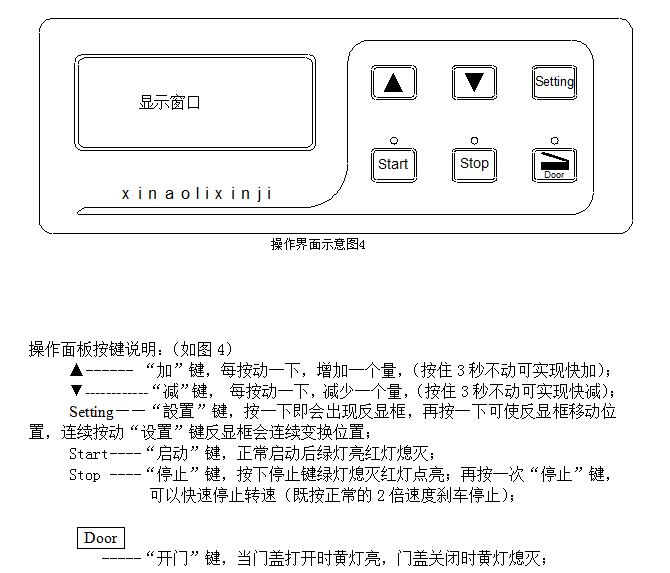

设置程序号:先按“Setting”(设置)”键,使反显框停留在ROTOr上,再按“▲”键或“▼”键,改变程序号。3秒后反显框自动消失。

设置转速:先按“Setting”(设置)”键,使反显框停留在Speed上;再按“▲”键或“▼”键,调整转速,按住“▲”键或“▼”键2秒不动即变为快加或快减,当速度显示接近所需值时,再点动“▲”键或“▼”键,使转速符合所需值。

设置离心力:方法同上;可以直接设置离心力,启动离心力;注意: ECF:00000xg 有两个功能:(1)在停止状态下,可以作为“离心力”输入窗口;在运转状态下则作为“离心力”时实显示窗口;

其他参数设置方法同上;

设定完成后,按“STRAT(启动)”键,绿灯亮红灯熄灭,速度显示会自动调速至设定转速(当转速达到设置值后,系统将记忆当前参数设定值,作为下次开机初始值),时间显示将以倒计时方式从设定的时间递减,当时间倒计时剩下最后5秒时,机器发出三声提示音,转头开始降速,直至完全停止。需要特别强调的是:“启动”操作时如果设定的离心时间或设置转速为零,机器将发出操作错误提示音,并禁止启动运行。

During the operation of the machine, the operator can modify any parameter of "speed", "time" and "centrifugal force"

Seven. Maintenance and precautions

※The machine should be placed in a dry and clean place. Humidity and dust will damage the machine and shorten the use time of the machine.

※ After the centrifugation work is completed every day, the rotor should be removed, cleaned and ventilated and dried. And avoid scratching the rotor body by colliding with hard or sharp objects. Because moisture is easy to accumulate in the refrigerated centrifuge chamber, a layer of grease is usually applied on the rotating shaft to prevent moisture. When the machine is not in normal use, it is better to place the desiccant in the centrifuge chamber.

※If the centrifuge tube is broken, the separation liquid will fall into the test tube hole of the rotor. It needs to be cleaned and dried in time, especially the bottom of the test tube hole. Regularly check whether the rotor has corrosion spots and small cracks. It is more necessary to check before use. It is forbidden to use corroded or cracked rotors to ensure safe use.

※If there is abnormal vibration and noise during the operation of the centrifuge, it indicates that the rotor load is asymmetrical or the weight of the test solution is too large. At this time, stop the machine immediately and check the load of the rotor to see if it is symmetrical and whether the weight of the test solution is too large. If it is still abnormal, ask a professional technician to check it.

8. Maintenance and service life of the rotor

※Regularly check the rotor, if there is corrosion or severe scratches or cracks, stop using it.

※After centrifugation work every day, use a clean soft cloth to wipe off the residual liquid and moisture on the surface of the centrifuge chamber and rotor, and take out the rotor to dry it for later use.

※The rotor should be prevented from falling and colliding.

※The temporarily unused rotors and centrifuge tubes should be taken out of the centrifuge chamber and stored in a clean and dry place.

※The working life of the rotor is limited. The various rotors used in this machine, under the condition of strictly adhering to the use and maintenance of the rotor, have a working life of five years (that is, the shelf life of the rotor is five years), and the shelf life of the rotor is five years. Counting from the date of leaving the factory, when the rotor is corroded, it will produce corrosion spots and fine cracks. The joint action of corrosion and stress will greatly weaken the strength of the rotor and shorten the life of the rotor, even if it is operated at a speed lower than the maximum allowable speed. , the rotor may also break suddenly. Therefore, it is strictly forbidden to use corroded and cracked rotors, and the shelf life of rotors is not applicable to corroded and cracked rotors.

※The rotors beyond the warranty period should be stopped immediately, and the manufacturer should be contacted and updated in time. The user shall be responsible for any damage to the rotor caused by corrosion or improper use.

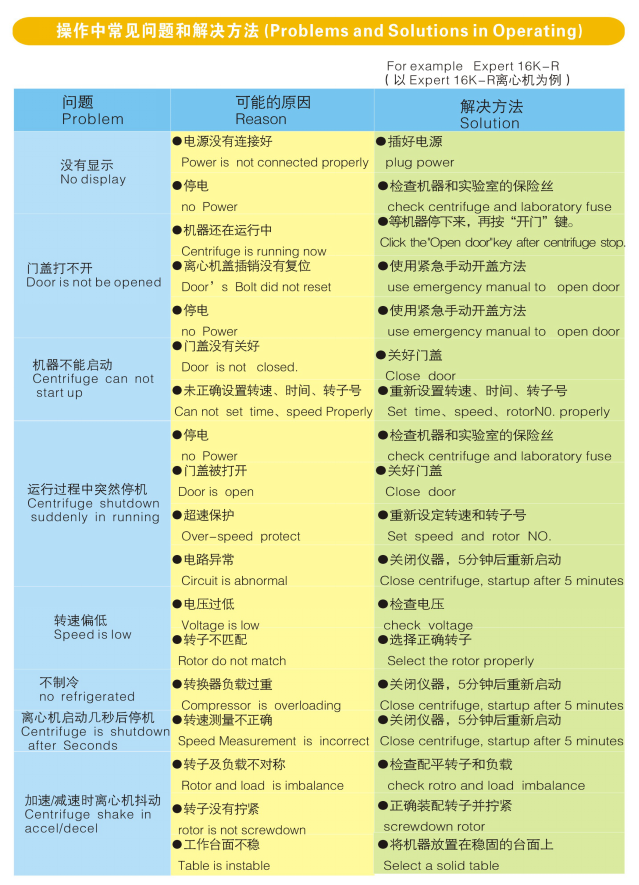

Simple faults and solutions