The casing of the engine is generally aluminum alloy die-casting. Aluminum is a relatively active western metal. After adding other elements to aluminum to make aluminum alloy, although the mechanical strength is improved, the corrosion resistance is reduced, which requires certain surface treatment according to the use environment.

①Blank inspection

Any obvious die-casting cracks, pores, cold grids and bumps on the blanks will affect the coating quality, and the blanks with defects will all be picked out; there are a lot of oil stains or release agents on the blanks, and corresponding degreasing treatment should be carried out ; Those who have serious defects in appearance size and assembly surface should be sorted and separated.

②Polishing and grinding

A sticky sand polishing cloth wheel is used, and the abrasive material is not less than 180# corundum. When polishing, prevent the large wheel from polishing the narrow surface and the small wheel from polishing the surface, so as not to cause polishing marks. The parts that cannot be polished and polished should be polished manually with special pneumatic tools, such as scrapers, files, sandpaper, etc., so that the surface of the parts can meet the coating requirements. Handle with care during operation to avoid bumping the machined surface.

③Liquid shot peening for engine assembly

The affected screw holes should be 100% protected. After protection, place the workpiece on the turntable of the shot blasting machine for shot blasting. The shot blasting air pressure is 0.4~0.5MPa.

The particle size of the glass shot is 40 days, and the shot peening time is 3~5 minutes. The workpiece can be rotated for multiple shot peening until it is sprayed. The shot peening angle is based on the angle of the maximum effective shot peening area, and the pressure should not be too high during shot peening, otherwise it will damage the surface of the substrate. After the shot peening is completed, remove the protective gear, and manually wash away the glass shot on the product and the aluminum chips and glass shot in the blind hole of the special workpiece.

④ Hanger

When the workpiece is hung up after pretreatment, the principle should be easy to clean, not damage the assembly surface, and not form air pockets. At the same time, special hangers should be used and handled with care.

⑤ Degreasing

For aluminum alloy parts, low alkalinity degreasing is usually used. The process parameters are: degreasing agent 5%~8%, high alkalinity below 10 points, pH=8~10, temperature 5°C~60°C, treatment time 3~5min. During the production process, the concentration of the bath solution should be regularly analyzed, the medicament should be added appropriately, the liquid level should be kept clear, and the bath solution should be replaced and discharged regularly. Alkaline degreasing formulas for aluminum alloys are given below.

NasP04l0~30g/LOP emulsifier 2~3g/LNa2SiO33~5g/L

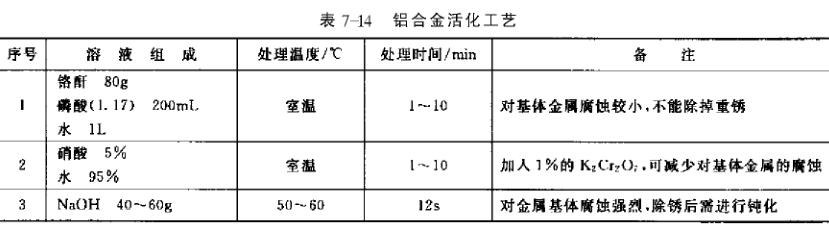

⑥ activation

Aluminum alloy is a western metal, which can be corroded by both acid and alkali. Process parameters are: activation

Agent 5%~8%, pH=1.5~3.5, normal temperature treatment 1~2min. The workpiece after activation should be washed with water several times. For the activation process of aluminum alloy, see Table 714.

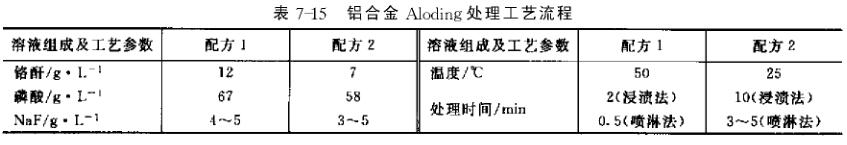

⑦Aloding processing

Also known as phosphoric acid, chromate treatment. The main components of the treatment solution are phosphoric acid and chromic acid, which contain fluoride or its compound salt as a corrosive agent, and the pH value of the solution is 1.5-3.0.

Through this treatment, an amorphous film composed of A12O3·2CrP0,·8H2O is formed on the surface of the substrate. The thinner treated film is suitable for the bottom layer of the coating film, and the thicker treated film has good corrosion resistance. In the process of Aloding treatment, with the increase of Al3+ high particles in the bath, its color will gradually become lighter, so the content of aluminum high particles in the bath should be controlled during production, and F-high particles should be added for coordination. The process flow of aluminum alloy Aloding treatment is shown in Table 7-15.

⑧ closed

After washing the workpiece after Aloding treatment, wash it in hot water not lower than 80°C for 1-2 minutes. When the temperature is constant, use flowing water as much as possible to maintain the pH value of the bath between 6 and 7.

⑨ drying

Before drying, try to use oil-free compressed air to clean the accumulated water on the surface of the parts and the residual glass pellets in some blind holes. Dry at 100~120°C for 15~20min. The dried product should be allowed to cool naturally or forcibly. It is strictly forbidden to mold the surface of the product to be coated at an angle with bare hands or dirty hands, so as not to affect the adhesion of the coating film.