The pros and cons of product quality are greatly affected by human factors, so it is necessary to check the coating quality at the coating construction site and give timely feedback to guide the on-site production. Every coating production line pays more and more attention to the coating quality of the construction site. Therefore, strengthening technical inspection during the coating process is an important means to ensure the coating quality and reduce the amount of workpiece repair. There should be an inspection post after the key process, so that the self-inspection of the operator and the inspection of the full-time inspector should be carried out simultaneously. According to the position or inspection content of the inspection process in the coating process, the quality inspection can be divided into pre-painting surface quality inspection, intermediate inspection and final inspection.

1) Surface quality inspection before painting

The pre-painting treatment is the foundation of the coating, and its quality has a great influence on the coating performance. In this process, special attention should be paid to checking the degreasing cleanliness and the appearance quality of the phosphating film. It mainly includes the following contents.

a. Check the surface quality of the parts to be painted entering the painting workshop according to the requirements of the painting process, and the unqualified products should be returned to the previous process for repair.

b. Check the concentration, temperature, cleanliness of washing water and spray volume of nozzles in each process of surface pretreatment before painting (such as degreasing, phosphating, etc.), and make records in time.

c. Check whether the surface condition of the parts to be coated after surface treatment meets the coating requirements. There should be no residual grease, dirt, rust, salt, alkali and water droplets on the surface, and the phosphating film should be uniform, dense and finely crystallized.

d. The water quality of the last washing water should be strictly controlled, such as phosphating treatment, electrophoresis and wet grinding, etc. In the occasions with high coating quality requirements, fresh high-quality water should be used for cleaning to prevent the salt in the water from accumulating on the coated surface , causing blistering of the coating film.

e. During the entire coating process after surface treatment, it is strictly forbidden to mold the piece to be coated at an angle with bare hands, so as to prevent the coating film from bubbling due to sweat.

2) Intermediate check

Intermediate inspection refers to the inspection of the coating quality of primers, intermediate coatings, etc. during the coating process. It mainly includes the following contents.

a. Check the dryness and hardness of each coating.

b. Check the surface condition of each coating: the primer should be uniform, without defects such as exposed bottom coating, pinholes, coarse particles, air bubbles, etc.;

c. Check the surface condition of the coating film after grinding: the surface of the coating film after grinding should be smooth and flat, without obvious sandpaper lines, and the grinding dust should be cleaned.

3) Final inspection

The final inspection refers to the quality inspection of the finished product after painting, which mainly includes the following contents.

a. Check the color, gloss and other surface conditions of the topcoat: the color and gloss should meet the requirements of the standard sample, and there should be no coating defects such as flow marks, particles, pinholes or shrinkage cavities, orange peel, and uneven gloss on the topcoat surface .

b. Check the drying degree, hardness and thickness of the topcoat: the coating film of the topcoat should be completely dry, the film thickness should be uniform, and reach the thickness and hardness specified in the technical conditions.

c. Periodic sampling inspection of the quality of the entire coating, and a comprehensive performance measurement. The sample can be prepared by hanging the sample on the vehicle, and the overall performance of the coating (such as hardness, adhesion, weather resistance, water resistance and salt spray resistance, etc.) can be measured.

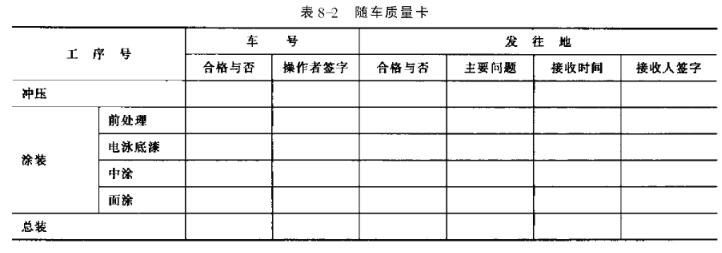

4) On-board quality card system

Some manufacturers, in order to ensure the quality of each process and clarify responsibilities, have established an on-board quality card system. The basic idea is to strengthen the quality supervision between each process, and transfer the intermediate product of each process to the next process as the final product of the process. Before leaving the factory, do a good job of product inspection to prevent unqualified products from entering the next process; before receiving them, the "user" also needs to do a good job of quality inspection, and unqualified products need to be returned to the previous process. The quality management card is finally It should be delivered to the user with the vehicle. The quality card with the vehicle is shown in Table 8-2 for reference.

The inspection method is generally visual inspection or non-destructive inspection with instruments. The setting of various inspection procedures depends on the product design's requirements for coating quality and the quality level. For coatings of different uses, the key content of the inspection is quite different. For example, for decorative coatings, focus on inspecting the coating defects that affect the decorative aspects, such as orange peel, pitting, sagging, richness, gloss, and integrity of the coating film; For the main coating, focus on checking the coating film defects that affect the corrosion resistance, such as the integrity, adhesion and thickness of the coating film. Therefore, the inspection content and the setting of the inspection process should be flexibly controlled according to the specific situation. Generally, the technical inspection process is set after the key process that plays a decisive role in the coating quality, such as phosphating, electrophoresis, puttying, grinding and surface coating. paint etc.