The coating environment has a great influence on the formation of the coating film, and has become an important factor affecting the coating quality. The painting environment includes the brightness, temperature, humidity, dust and fire prevention measures of the painting workshop. The following conditions can be considered as a good environment for painting in the automotive industry: bright and uniform brightness, temperature in the range of 15-30°C, relative humidity of the air in the range of 50%-70%, clean and dust-free air, proper ventilation, And there are fire prevention measures.

Daylighting and lighting

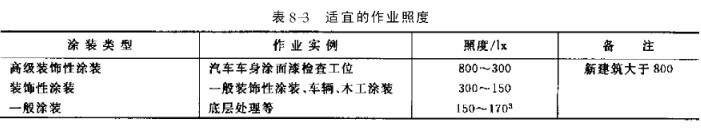

The coating quality requirements are different, and the illumination benchmarks required for coating operations are different (see Table 8-3).

According to the lighting design standards of industrial enterprises, the lighting level of the painting workshop is at the N level, and the indoor natural light intensity should not be lower than that of the 501L painting workshop, which depends on the window lighting, lighting and the brightness of the indoor object surface. For indoor work, windows and skylights should be used to introduce natural light, rather than direct sunlight, and the uniformity of brightness should also be considered. If the area of the window reaches more than 1/5 of the workshop area, the lighting is good. Most of today's painting workshops rely on artificial lighting (factory lighting and workstation lighting), but it is necessary to make the entire lighting brightness uniform.

The illuminance of the work surface recommended in Japan is as follows.

Decorative and precise operations are greater than 3001x; general operations are greater than 1001x; rough and miscellaneous operations are greater than 701x1)

Partial lighting can be used for precise operations such as coating surface inspection, spray booth, and repair coating, and natural daylight-colored light sources or natural white light sources should be used. The light source generally uses fluorescent lamps. In order to prevent discoloration, care should be taken to select the type of fluorescent lamps. Natural fluorescent lamps or natural white fluorescent lamps are used in workplaces that need to identify the color of paint; Fluorescent lights are better.

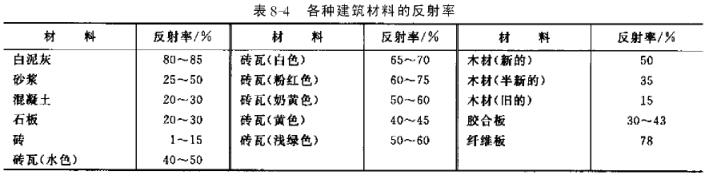

The inner surface of the building adopts materials with high light reflectivity (high brightness) and materials with high brightness, which can improve the indoor illumination. When the reflectivity of the ceiling is more than 85%, that of the wall is 60%~70%, that of the floor is 20%~30%, and that of the mechanical device is 20%~30%, the working environment with stable brightness can be obtained.

The reflectivity of various building materials is shown in Table 8-4.

temperature and humidity

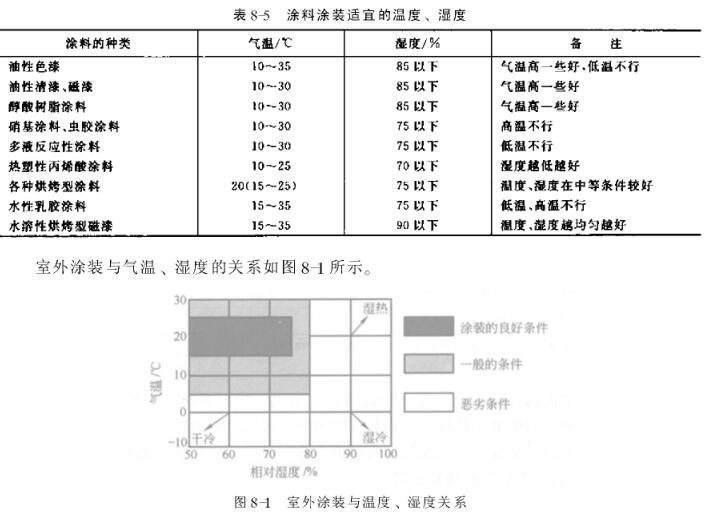

Atmospheric temperature and humidity have a great relationship with the drying and construction performance of the coating. If the temperature is below 5°C, the coating will dry very slowly; if the temperature is too high, the solvent will evaporate too quickly, which will affect the leveling property; The coating is "whitened" and the performance of the coating film is reduced. Therefore, painting should be avoided in cold and humid places. See Table 8-5 for the suitable temperature and humidity for coating.

The substrate should be well-dried, and the surface of the substrate is prone to condensation when the temperature is lower than the air temperature. The surface temperature of the substrate needs to be 1~2℃ higher than the air temperature.

In the case of electrostatic coating, the temperature and humidity are required to be constant, because changes in temperature and humidity will affect the uniformity of coating film thickness, dryness, smoothness, gloss and color, etc., and affect labor efficiency. The most suitable conditions are to keep the temperature above 10°C and the humidity below 75%, so heating is required in winter, cooling is required in summer, and dehumidification is required in high humidity. Therefore, humidity control, temperature control and dust removal devices are generally installed in the spray booth.

The best environmental conditions for spraying water-based intermediate coats and top coats are the temperature is ~26°C, the relative humidity is 50%-70%, 40%-80% is also acceptable, but the formula needs to be slightly adjusted. In the case of low humidity and high temperature, the water evaporates quickly, causing unevenness at the edge. In the case of high humidity and low temperature, proper rheological control can be done.

Health prevention and ventilation

Dust in the air is the enemy of coating, and proper dust prevention measures must be taken to obtain a good coating film.

Dust in the atmosphere not only refers to coarse particles, but also includes various organic atmospheres attached to the coating film that affect the appearance. These substances have a bad influence on the performance and durability of the coating film, and it is generally necessary to take appropriate methods to remove dust with a particle size of 10 µm or more.

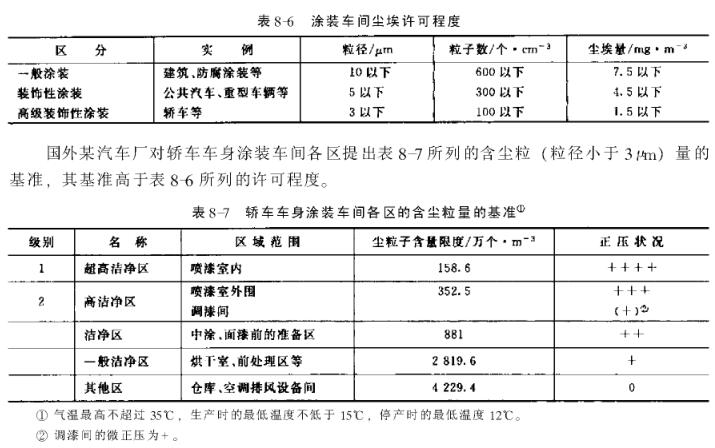

See Table 86 for dust permit level in paint shop.

The process design of modern painting workshops is not only arranged according to the temperature zone, but more importantly, according to the required cleanliness level, and requires the clean area to maintain a slight positive pressure to prevent the outside dusty air from entering. In addition, the dust brought in by the staff is also an important source of dust, so before the foreign coating staff enters the work area, they should take a professional wind bath to clean the dust on their bodies, and it is not allowed to wear clothing that is easy to shed fibers, especially in the electrostatic coating area , more attention should be paid.

In order to maintain the wind speed and slight positive pressure in the painting room, independent air supply and exhaust systems are set up. In order to eliminate the accumulation of harmful gases and create a safe and hygienic working environment, proper ventilation and supply of fresh air are required in the painting workshop.

In a general painting workshop, the appropriate ventilation rate is 4-6 times/h of the total indoor volume, and 10-2 times/h in the paint mixing room. In addition, it can also be calculated according to the toxicity conversion of organic solvents.

In addition, the air supply and exhaust in the workshop should be balanced, and some work areas should be guaranteed to be slightly positive pressure, that is, the air supply volume is greater than the exhaust air volume, but the air supply should be dust-removed, temperature-regulated, and humidity-controlled.