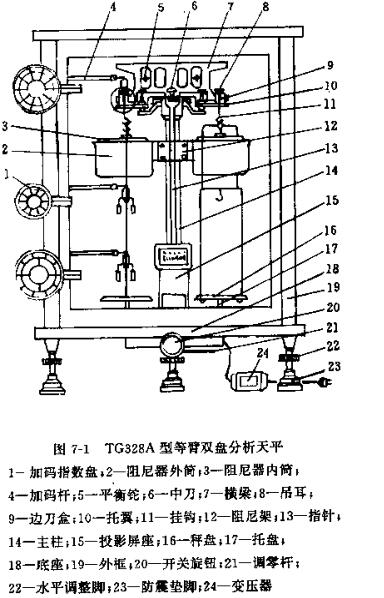

The equal-tube double-disk analytical balance is currently the most commonly used one. According to the difference in the mechanical weighting part, it is divided into semi-automatic and fully automatic (partial mechanical weighting and full mechanical weighting). Now take the TG-328A isometric double-disc analytical balance as an example to introduce its structure and usage. TG-;128A isometric double-disc analytical balance is a sub-photoelectric fully automatic optical reading balance (see Table 7-3). Its structure is shown in Figure 7-1. Its usage is as follows:

(1) Preparation before weighing

Zero adjustment

Adjust the zero point to "0" on the projection screen before weighing. After the balance is turned on, the bright light of the projection screen should illuminate the moving differential scale, and when the scale stops, it should coincide with the zero line of the projection screen. Otherwise, adjust the balance screw to make them overlap.

Sensitivity adjustment

On the photoelectric analytical balance, the weight below 10rng is represented by the differential scale on the projection screen. After adjusting the zero point, you can check whether the differential scale on the projection room is exactly at the position of 10 mg when the left pan is loaded with a weight of 10 mg. If the marked weight is too large, you should move the inductance adjustment ring down to lower the center of gravity of the balance beam to reduce the sensitivity; if the indicated value on the projection screen is less than 10rng scale, you should increase the center of gravity of the balance beam by adjusting the nut , to increase the sensitivity. It should be noted that the zero point must be adjusted after each adjustment of the sense volume. Until the sensitivity is appropriate, and the screen can accurately display 10mg.

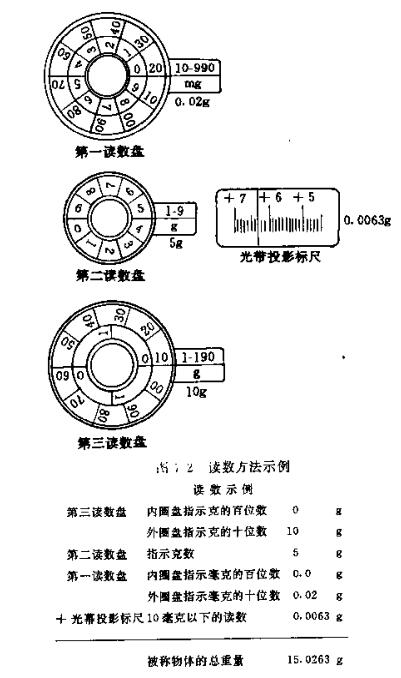

After weighing and adjusting the zero point and sensitivity, you can put the weighing sample into the left pan. When weighing with TG328B semi-automatic optical reading balance, the weight above 10g should be taken out from the weight box and placed on the right plate; Index plate. The reading method is shown in Figure 7-2.

(2) Weighing method

There are four weighing methods: direct pressing method, compound weighing method, displacement method and Mendeleev method. Among them, the direct method is further divided into the sensitivity method and the restoration zero point method. The sensitivity method has been introduced in "Technical Correction of Weights". The method of restoring the zero point is described below.

The return-to-zero method is a weighing method for swing balances. Put the weighing sample on the left plate of the balance, and add the weights to the right plate of the balance according to the weight from large to small. coincides with zero. At this time, the total weight of the weight and the ring code is the weight of the sample. Then, when the connecting weights are put back into the box, the masses of the weights are accumulated sequentially so as to check for correctness.

In order to avoid the error caused by the sample oxidation, moisture absorption and interaction with the carbon dioxide drum, the sample should be put into a weighing bottle and weighed. For example, weigh W, g, then pour out the approximate weight of the required sample into another clean container prepared in advance, and weigh the remaining part together with the weighing bottle to get w2g. The weight poured out in this way is (W,-w2)g. This method is also called subtraction method. If you want to continuously weigh several samples, you can continue this operation to get W3g, W4g, etc., then the second weighing is (W2-W3)g, and the third weighing is (W3-W4)g wait.

When the accuracy requirement is high, in order to eliminate the error of the unequal tube, the compound weighing method can be used. Put the weighing sample on the left plate, weigh once by direct method, set the weight at this time as w; then exchange the positions of the weighing sample and the tray where the weight is on, and weigh again, set the weight The code weight is w,. If the real weight of the sample is W, the left arm of the balance is L1, and the right arm is L2, then the following calculation formula is obtained: