I. Introduction:

The specular gloss meter is a measuring instrument for measuring the specular gloss of the surface of flat products such as paint, plastic, paper, enamel, natural stone veneer, aluminum and gold. WGG series specular gloss meter is a new type of intelligent gloss measurement and testing instrument developed and produced by our company. It is a high-tech product integrating precision optical technology, microelectronics technology and modern computer technology.

WGG20 WGG60 WGG85 Specular Gloss Meter is a pocket-sized fixed-angle intelligent gloss meter testing instrument, and the fixed angle is divided into: 20°, 60°, 85°. It has the advantages of accurate measurement, good repeatability, high reliability and complete functions.

2. Main features:

WGG20, WGG60 and WGG85 specular gloss meters have the following main features:

*Single-chip microcomputer control, intelligent function;

*Digital circuit working mode;

*With automatic zero calibration, no zero adjustment is required;

*It can be tested when it is turned on, no preheating is required, and the power consumption is low;

*Standard gloss board parameter storage function, also can be modified by oneself;

*Key automatic calibration;

*LCD digital display, accurate indication;

* The whole machine is small in size, light in weight and easy to carry;

*Portable design, suitable for on-site measurement;

*The power supply of the whole machine can be AC/DC dual-purpose power supply, charging for 10 hours, and can work continuously for 10 hours.

3. Working principle

1. Basic principles

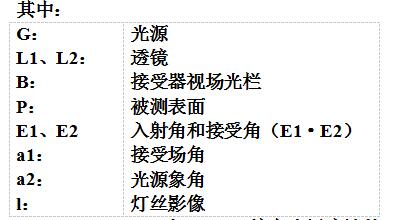

The specular gloss meter uses the principle of light reflection to measure the specular gloss of the sample relative to the specular gloss standard plate. WGG series specular gloss meter adopts fixed-angle parallel optical path.

The E1 (E2) of WGG20, WGG60 and WGG85 specular gloss meters are 20°, 60° and 85° respectively.

2. Working principle

WGG20, WGG60, WGG85 specular gloss meter adopts single-chip microcomputer control and comparative detection circuit.

4. Applicable standards

WGG20, WGG60 and WGG85 Specular Gloss Meters are suitable for the determination of the 20°, 60° and 85° specular gloss of the paint film of the international and foreign standards ISO2813 paints and varnishes - paint films without metallic pigments.

ASTM D523 Standard Test Method for Specular Gloss.

ASTM D1455 Standard Test Method for 60° Specular Gloss of Latex Floor Polishes.

ASTM D2457 Standard Test Method for Specular Gloss of Plastic Films.

JIS Z8741 Test method for specular gloss.

WGG20, WGG60 and WGG85 specular gloss meters are also applicable to the domestic standards corresponding to the above standards.

GB9754 Determination of 20°, 60° and 85° specular gloss of paint films of paints and varnishes without metallic pigments;

GB8807 Test method for specular gloss of plastics.

5. Scope of use:

WGG20, WGG60 and WGG85 specular gloss meters are equivalent to ISO2813. According to the suggestion of ASTM D523: the 60° method gloss meter can be applied to most samples (including medium, high-low gloss meter products); the 20° method can improve the identification ability for high gloss samples, and is suitable for samples with a gloss higher than 70 gloss units; The 85° method can improve the identification ability for low-gloss samples, and is suitable for samples with a gloss lower than 10 gloss units.

WGG20, WGG60 and WGG85 have a wide range of applications, and are suitable for all industries that use paint, coatings and other coatings. Such as: used to measure the glossiness of the sprayed surface of automobiles, machine tools, furniture, household appliances and other products. It is also suitable for plastic products, packaging and decoration, and indoor and outdoor decoration.

The test methods of WGG20, WGG60 and WGG85 are in full compliance with international standards, and can provide reliable basis for the inspection and measurement of imported and exported products of enterprises and institutions.

6. Operation method:

1. Measurement preparation

The instrument adopts AC/DC dual-purpose power supply. When using AC power supply, insert the spare external power plug into the "DC9V" jack of the instrument, and connect the other end of the external power supply to ~220V. When using DC power supply, unplug the power plug on the instrument, and the instrument works with the internal rechargeable battery. When there is a ~220V power supply, please use more AC power supply to avoid measurement errors caused by insufficient voltage of the internal rechargeable battery when the instrument is used for a long time.

After the above power supply is selected, turn on the power switch of the instrument, and "PL" should be displayed on the instrument LCD.

2. Settings

Press the "Setting" key, and the "←" mark will appear on the upper left corner of the LCD screen. If the displayed data is the same as the standard plate value provided with the instrument, there is no need to modify the standard value. Press the "Setting" key again, and the "←" mark will disappear. "PL" is displayed at the same time, indicating that the standard value has been set.

If the displayed data is inconsistent with the standard value, the modification method is as follows:

If the display data is "90.0", if the standard plate value is "92.8", press the compound key "Measure/▲", and the displayed data will increase until "92.8". If the standard plate value is smaller than the displayed data "90.0", or the preset is too high, press the compound key "calibration/▼", and the displayed data will decrease until the standard value you require.

After the standard value of the standard plate is preset, press the "Setting" button again, the "←" mark on the upper left corner of the display screen will disappear, and "PL" will be displayed at the same time, indicating that the setting is completed.

3. Calibration:

将仪器的测量窗口置于黑色标准板上,仪器外壳上的“V”标记对准标准板侧面的刻线,按“校标/▼”键后仪器将显示设置的标准板值,表示校标功能已完成。

4、线性校正:

将仪器置于中(或低)光泽度仪标准板上,仪器外壳上的“V”标记对准标准板侧面的刻线,按“测量/▲”键,此时仪器显示器的显示值与该板标称值偏差应不小于1.2光泽度单位,表示仪器线性度正常。

注:当测量值与标准板值偏差超过±1.2光泽度单位时,首先应检查测量时仪器放置位置是否正确,上述因素排除后应检查高、中(或低)光泽度仪标准板表面,可能被污染,可用镜头纸轻擦去污,重复“3”、“4”条测量方法,如测量数据仍超差,应与生产单位联系解决。

5、样品测量:

将仪器置于被测样品上,按“测量/▲”键,此时仪器显示屏的显示值即为被测样品的光泽度数据。

6、交直流二用供电:

仪器内装有六节可充电镍镉电池,其容量为300MAH,不论仪器采用直流电池供电或交流电源供电,均经三端稳压器稳压,输出5V直流电压供仪器工作。使仪器不因外界电源或电池电压变化,稳定地工作在5V电压。

为延长镍镉电池的使用寿命,充电电流控制在50MA左右,使用外接电源工作时,仪器开机状态,镍镉电池充电电流为30MA-40MA,所以使用外接电源可以实现仪器边工作边充电。

七、主要技术参数:

1、测量范围: 0-199.9

2、分度值: 0.1

3、重复性: ±0.4

4、示值误差: ±1.2

5、工作电流

静态工作电流: 20MA

测量工作电流: 30MA

6、使用条件

环境温度: 10℃~40℃

相对湿度: 不超过75%

7、仪器(长×宽×高) 16cm×4.2cm×10cm

8、仪器重量: 0.78kg

八、仪器维护和注意事项:

1、本仪器集模拟、数字、微机电路和光学系统于一体的精密测量仪器。仪器就保持清洁、干燥,镜头有灰尘或污垢可用吹球吹净或用镜头纸轻擦。

2. Keep the two standard boards equipped with the instrument clean and dry. Do not touch the boards with your fingers. During the instrument calibration process, minimize the friction between the working surface of the instrument and the standard plate, thereby ensuring the stability of the standard plate parameters and prolonging the service life of the standard plate. If there is dust on the surface, it can be blown off with a blower or cleaned with a soft brush. If there is dirt on the surface, wipe it with lens tissue.

3. The instrument does not need to be preheated, and it can be used within 10 seconds after starting up. Every time the power is turned on, a calibration step is performed. When the standard plate is not in use, please put it in the drying cylinder.

4. Use the internal battery to work. After the instrument is measured, please turn off the power switch to save electricity.

If the "----" mark appears on the LCD, it means a low-voltage alarm, indicating that the nickel-cadmium battery needs to be charged.

If the "00.0" mark appears on the LCD, it means that the operation is wrong, please restart the machine.