One-piece ordinary type; with the characteristics of small measurement error, high reliability, good stability, and easy operation, it is an indispensable non-destructive testing instrument for controlling and ensuring product quality.

1. Product description

* This instrument is a battery-powered portable measuring instrument, which uses the principle of magnetic induction and eddy current. The measurement method complies with international standards ISO2178, ISO2360 and national standards Gb4956, Gb4957. It adopts computer technology, non-destructive testing technology and other professional technologies to accurately measure the thickness of the measured object without damaging it.

* The NF probe can measure the thickness of the insulating covering layer on the non-magnetic metal substrate, such as paint, plastic, rubber coating on the surface of aluminum, copper, zinc, non-magnetic stainless steel, etc., and can also measure the thickness of aluminum or aluminum alloy materials. Anodized layer thickness.

*The spring guide sleeve probe with wear-resistant hard metal probe can not only measure on hard or rough surfaces, but also ensure that the probe has constant pressing force and stable sampling value.

* Wide measurement range and high resolution.

* Automatic memory calibration value, easy to use.

*Small size and light weight.

*Digital backlight display, no parallax.

*Using optional RS232C software and cables, it can communicate with PC computer to realize functions of data collection, processing, analysis and printing.

*The instrument is equipped with automatic shutdown to realize power saving function.

2. Technical specifications

Display: 4-digit backlit LCD

Standard test range: 0~1250 um

(Other measurement ranges can be customized)

Resolution: 0.1 um (below 100um)

1um (less than 100um)

Measurement accuracy: ±1~3%n or ±2.5 um

Thinnest substrate: 0.3mm

Minimum curved surface: convex 3mm/concave 50mm

Measurement mode: single measurement and continuous measurement

Operating conditions: temperature 0°C~50°C; humidity <80% Power supply: 2x1.5vAAA7# batteries

Size: 130x63x24mm

Weight: 90g (without battery)

Standard accessories

*host

*Iron base

* Aluminum base

*Wrist strap buckle

*Calibration diaphragm

*Carrying case

*user's Guide

Optional accessories

* USB data line output

* RS-232C data line interface

* Bluetooth Bluetooth data output

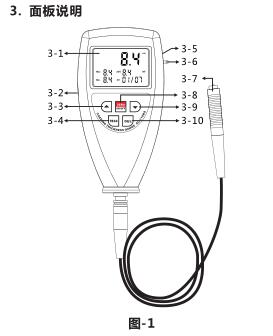

4. Measurement procedure

4.1 Press the power button lightly, and after turning on the power of the whole machine, the instrument will automatically enter the measurement state and automatically restore the parameter settings before the last shutdown.

4.2 After confirming that the calibration is correct, the measurement can be started. If there is any doubt about the previous calibration, another calibration should be performed. The specific method of calibration is detailed in the calibration part of the instrument. Once the instrument is calibrated, the calibration results will be automatically stored in the instrument, and the next time the instrument is turned on for measurement, it is not necessary to calibrate again unless there is doubt about the accuracy of the measurement.

4.3 Press the measurement sensor onto the coating to be tested, and the value on the display is the measured value of the coating to be tested.

Note: Since all magnetic coating Thickness Gauges use the principle of electromagnetic induction; non-magnetic coating Thickness Gauges use the principle of eddy current, so it must be noted that the speed of the probe pressing on the measured object should not be too slow. Otherwise, it will cause artificial measurement error.

4.4 For the next step of measurement, it is necessary to lift the measurement sensor to more than one centimeter, and then repeat the above steps. The instrument can automatically store each measurement value, and at the same time, the maximum value, minimum value, average value and measurement times are displayed on the screen.

4.5 To change the measurement unit, just press and hold the power button until "UNIT" appears on the display and let go. (It takes about 6 seconds from pressing the power button until UNIT appears)

4.6 If you want to change the measurement mode and realize the conversion between single measurement and continuous measurement, you can also lightly press the power button until SC appears on the display and then release the button (it takes about 8 hours from pressing the power button until SC appears seconds). When the instrument is turned on and not measuring, if there is no symbol " " displayed on the display (displayed only during measurement), it means a single measurement mode, and the buzzer will sound once for each measurement. If " " is always displayed, it means continuous measurement mode, and the buzzer will not sound during measurement.

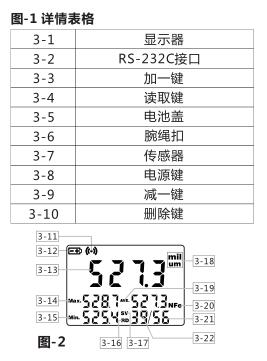

5. Statistics

5.1 This instrument can automatically complete the statistics and analysis , including:

A. Average of measurements. (Symbol "AVE" indicates)

B. Maximum and minimum values at the time of measurement. ("Max" means the maximum value, "Min" means the minimum value )

C. Measurement times and statistics

5.2 When the measurement matrix "F" and "NF" are switched or restarted , the data on all displays will be re-stated according to a new round of data.

5.3 When the stored data exceeds 99 groups, after the last measured value is automatically stored, the earlier measured value will be automatically deleted, and so on.