1. Product description

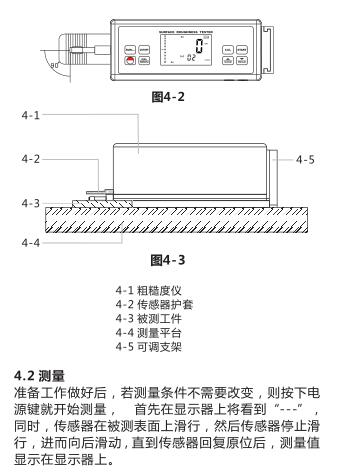

The instrument adopts computer technology and conforms to the national standard GB-T6062 and four standards of ISO, DIN, ANSI and JIS. It can be widely used in the production site and can measure the surface roughness of various machined parts. It can be calculated according to the selected measurement conditions. Corresponding parameters, all measurement parameters are clearly displayed on the liquid crystal display. When measuring the surface roughness of the workpiece, the sensor is placed on the measured surface of the workpiece, and the driving mechanism inside the instrument drives the sensor to slide along the measured surface at a constant speed. The sensor feels the roughness of the measured surface through the built-in sharp stylus. The roughness of the measured surface of the workpiece causes the displacement of the stylus, and the displacement changes the inductance of the inductance coil of the sensor, so that an analog signal proportional to the roughness of the measured surface is generated at the output of the phase-sensitive rectifier. After amplification and level conversion, it enters the data acquisition system. The DSP chip performs digital filtering and parameter calculation on the collected data, and the measurement results are displayed on the LCD. At the same time, it can communicate with the PC to realize data analysis, statistics and printing.

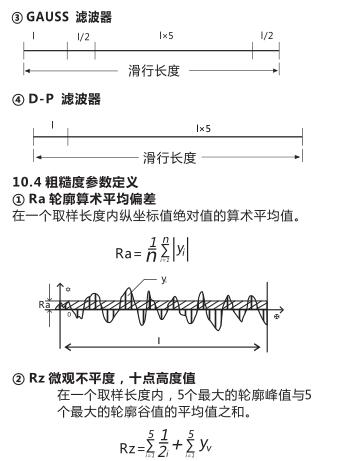

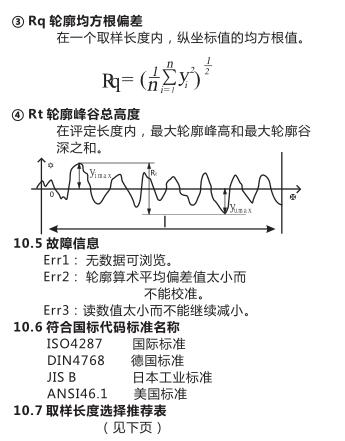

*Multi-parameter measurement: Ra, Rz, Rq, Rt

* High precision inductive sensor;

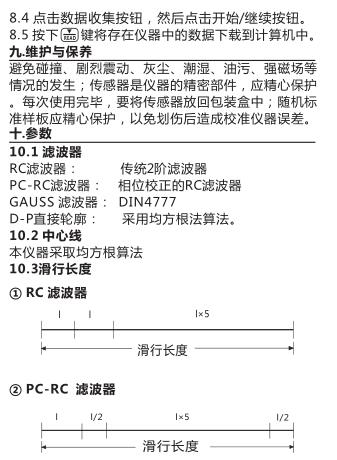

*RC, PC-RC, GAUSS, DP four filter methods;

*Built-in lithium-ion rechargeable battery and charging control circuit, high capacity;

* Mechanical and electrical integration design, small size, light weight, easy to use; built-in standard RS232 interface, can communicate with PC;

*This watch has two shutdown methods: one is manual shutdown, and the other is automatic shutdown after 5 minutes of keyboard operation.

*This table can memorize 7 sets of measurement data and measurement conditions for next viewing or online processing.

* With metric and imperial conversion function.

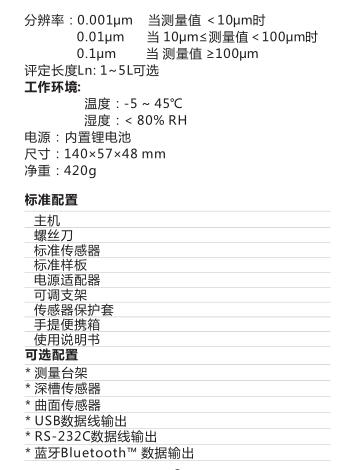

2. Specifications and parameters

Display: LCD

Measurement parameters: Ra, Rz, Rq, Rt

Measuring range: Ra: 0.005~16μm/0.020~629.9μinch

Rq: 0.005~16μm/0.020~629.9μinch

Rz: 0.020~160μm/0.780~6299μinch

Rt: 0.020~160μm/0.780~6299μinch

Accuracy: no more than ±10%

Indication value variability: not more than 6%

sensor:

Angle: 90°

Radius: 5um

Measuring force: 4mN (0.4gf)

Material: Diamond

Measuring principle: inductive

Maximum driving stroke: 17.5mm/0.7inch

Sampling length (optional): 0.25mm/0.8mm/2.5mm

Drive speed:

When measuring:

When sampling length=0.25mm, Vt=0.135mm/s

When sampling length=0.8mm, Vt=0.5mm/s

When sampling length=2.5mm, Vt=1mm/s

When returning:

Vt=1mm/s

Filter profile: (filter profile: RC/PC-RC/GAUSS)

(Unfiltered contour: DP)