1. Instrument characteristics

* Can display "displacement", "velocity" and "acceleration" three measurement parameters at the same time.

* Conforms to international standard ISO2954 for periodic motion measurement to detect imbalance and deviation of moving machinery. *Specially designed for on-site measurement of various mechanical vibrations, in order to provide data for quality control, running time and prior equipment maintenance.

* Select high-performance accelerometers to achieve accurate and repeatable measurements.

* Convert to vibration signal with piezoelectric acceleration sensor. *With bearing condition measurement function.

* Liquid crystal LCD display, light weight, and simple operation, easy to use.

*Wide frequency range, in the acceleration mode, the frequency can reach 10-10KHz.

*With AC signal output, it is convenient for auscultation and recording. *Optional earphones can be used as a stethoscope.

*Using optional RS-232c software and cables, it can communicate with PC computer to realize functions such as printing and statistics.

2. Technical Parameters

Display: 4-digit 18mm liquid crystal display

Sensor: piezoelectric vibration sensor

Accuracy: ±5%+2 words

Measuring range:

Displacement: 0.001~4.000 mm peak-to-peak

Speed: 0.1~400.0 mm/s true effective value

Acceleration: 0.1~400.0 m/s² peak

Frequency Range:

Displacement: 10Hz~1KHz

Speed: 10Hz~1KHz

Acceleration: 10Hz~10KHz

Operating conditions:

Temperature: 0~50℃

Humidity: < 90%

Output: 2.0v AC load resistor 10k

Size: 140x70x30mm

Power supply: 4x1.5vAAA (UM-4) No. 7 batteries

Weight: about 130 grams (excluding batteries)

Standard accessories:

* Host

* Magnetic suction seat

* Probe (conical)

* Probe (ball type)

* Measuring sensor

* Carrying case

* user's Guide

Optional accessories:

* earphone

* USB data cable

* RS-232C cable and software

4. Measurement procedure

4. 1 Connect the piezo sensor to the instrument and turn it until it locks.

4.2 Use the magnetic suction seat to fix the piezoelectric sensor on the point to be measured. Make sure that the surface to be fixed is flat and clean. If possible, please install it directly with screws.

4.3 Press the power button lightly to turn on the power; three measurement parameters are displayed at the same time.

5. Selection and measurement overview of vibration parameters

5.1进行振动测量时,应测量哪个参数? “加速度”、 “速度”和“位移”是三个常用参数,给出的结果准确且有重复性,其他测量参数还未被证明是可靠而准确的。但是,对有些场合,转速测量和频率测量也是十分重要的。 加速度测量具有极好的高频测量性能。因此在判断轴承和齿轮箱的故障时非常有效。

①速度测量是振动分析中常用的参数。对于不同功率的机械类别,在判断机械振动是否可接受时,According toISO2372、

BS4678或者VD2056,速度将是判断的指南。 说明书附表中列出了机械的类别。②位移测量多用于低速运转的机械,其特点是低频特性良好,但当安装轴承时,位移测量效果就不称心。

5.2振动测量概述

振动测量是判断机械良好或某一特定设备运转是否正常的可靠尺度。 一个称心的机械设备,若几乎没有振动,说明电机以及周边设备如齿轮箱、电风扇、压缩机等比较平衡、无偏离,安装良好;在实际中,很大比例的安装远不够称心;未对正、失衡的安装直接给支撑件如轴承等增加额外的张力,最终导致关键部件的磨损,造成效率低、发热,甚至瘫痪;当机械设备磨损和恶化时,设备的振动会增大,因此振动测量在设备的预先维护和减少停工方面具有极为重要的意义;监测机械设备的振动,在它成为重大问题前,就检测出它的恶化,以便必要时提前订购备件和维修。通过一段时期的连续监测,绘出趋势图,将这些有价值的数据添加到设备的历史记录中。

5.3什么是趋势图

趋势图就是被监测的振动参数随时间变化的一种表示方法。对于有规律的振动,画出振动参数在一定时间内的变化,就会表示出某一设备的发展情况或恶化情况。典型地,设备在安装后,无论是新的或修理过的,当设备运行时都会稍微变差,稍后将在一段正常的寿命期内,保持不变。当部件磨损时,振动加剧。这种趋势有助于帮助维修工程师提前预测故障时间,尽可能地利用该设备,同时订购备件和制订维修计划,以利生产。

6.更换电池

6.1当电池电压约5 V时,显示器上将出现电池符号,需要更换电池。

6.2 Install the battery correctly according to the indication on the battery box. 6. 3 If the meter will not be used for a long time, please take out the battery to prevent the battery from rot and damage the meter.

7. Measurement precautions

7.1 The connecting cable of the sensor is easy to cause noise, and the cable winding and large shaking should be avoided. Another source of noise is poor contact of connectors, which should also be paid attention to.

7.2 The instrument should not be used in the environment of strong electromagnetic field interference or corrosive gas, and should avoid strong vibration and impact.

7.3 The sensitivity of the instrument is adjusted at the factory according to the sensitivity of the equipped sensor, so do not exchange the sensor arbitrarily.

7 .4 Each measurement should be carried out when the machine is in the same running state. Changing the running state may cause the vibration quantity to change, thus drawing incorrect conclusions.

8. Key points of vibration measurement

8.1 Select the appropriate location and direction of the measuring point. Usually the measuring point should be on the rigid (not weak) structure of the stressed part, such as the bearing housing, and measure in three directions: horizontal, vertical and axial.

8.2 The part of the measuring point should be flat and clean, so that the magnetic suction seat of the sensor and the measuring point have a good plane contact, so that better frequency response characteristics can be obtained.

8.3 Each measurement should be carried out at the same position and direction. For this purpose, marks should be made at the positions of the measuring points.

8.4 Measure the vibration of the machine at regular time intervals (such as daily or weekly), and make a good record of the data, so as to make a correct diagnosis by analyzing the vibration change and development trend.

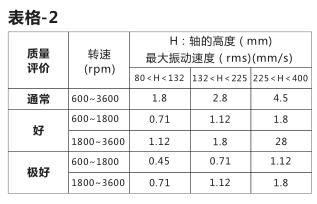

9.1 ISO-2 372 recommended vibration assessment standards for various machines (see the table on the next page)

The vibration intensity in the table is defined as the maximum effective value of the vibration velocity measured at important positions of the machine (such as: bearings, anchors, etc.).

Class I: small machines, electric motors; ≤15KW.