1. Product Features

* Comply with international standard ISO2954, GB13823.3, for periodical motion measurement to detect unbalance and deviation of moving machinery.

* Designed for on-site measurement of various mechanical vibrations to provide data for quality control, running time and prior equipment maintenance.

* Three piezoelectric accelerometers with high performance are selected to realize three-dimensional vibration measurement with high accuracy and good repeatability.

* It has bearing condition measurement function.

* Liquid crystal LCD display, one display can display three vibration parameters (velocity, acceleration , and can also display a selected parameter of three-dimensional vibration at the same time.

* Lightweight and easy to operate, easy to use.

* Wide frequency range, up to 10-10KHz.

* Auto power off function.

* With AC signal output, it is convenient for auscultation and recording.

* Optional earphones can be used as a stethoscope.

*Using optional RS232 software and cable, it can communicate with PC computer to realize functions such as printing and statistics.

2. Product parameters

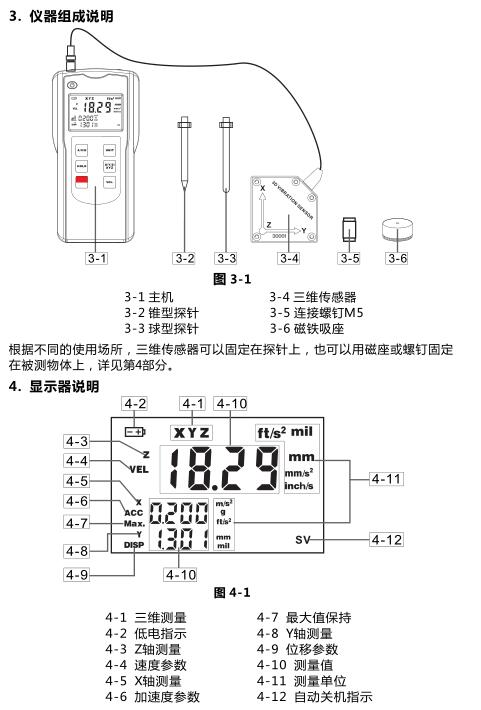

Display: 4-digit liquid crystal display for displaying values and measurement status

Sensor: Three-dimensional piezoelectric accelerometer, that is, three piezoelectric sensors of X, Y, Z axes are combined into one sensor

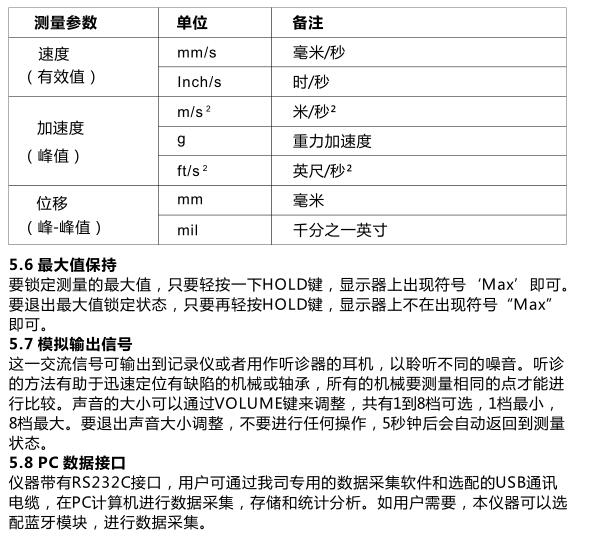

Measurement parameters: velocity, acceleration and displacement

Measuring range:

Acceleration: 0.1-400.0 m/s² peak 0.3-1312 ft/s²; 0.0-40g

Speed: 0.1-400.0 mm/s True RMS 0.004-16.00 inch/s

Displacement: 0.001-4.000 mm peak-to-peak value 0.04-160.0 mil

Frequency range: 10-19KHz

Accuracy: ±5%+2 words

Output: AC 2.0V, load resistance 10K

Shutdown: 2 modes, manual shutdown at any time, automatic shutdown after 5 minutes of last keyboard operation.

Operating conditions: temperature 0-50°C

Humidity: < 95%

Size: 140x70x30mm

Power supply: 4x1.5vAA 7# battery

Weight: 130g (without battery)

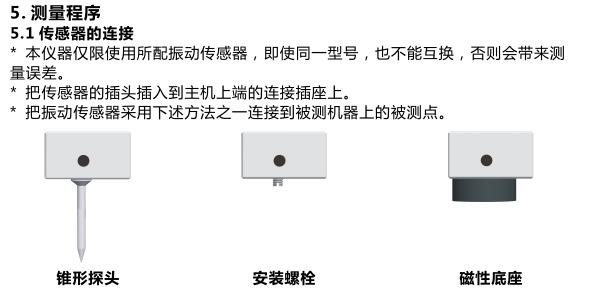

Standard accessories:

1. Magnetic suction seat.................... 1 piece

2. Three-dimensional piezoelectric sensor........ 1

3. Probe (taper type)..................... 1 piece

4. Probe (spherical) ..................... 1 piece

5. Carrying case................................. 1 piece

6. Instruction manual...................1 copy

Optional accessories:

1. Earphone stethoscope

2. RS232C or USB cable and software

3. Bluetooth

4.1 Installation principle of vibration sensor

* Ensure that the detection point of the vibration sensor can correctly reflect the vibration characteristics of the measured object.

* Make sure that the main sensitive axis of the vibration sensor is consistent with the direction to be measured by the measured object.

* Make sure that the vibration sensor is fixed reliably and in close contact with the measured object.

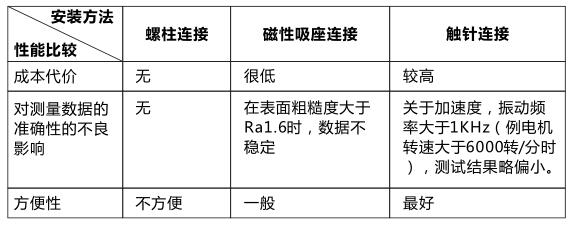

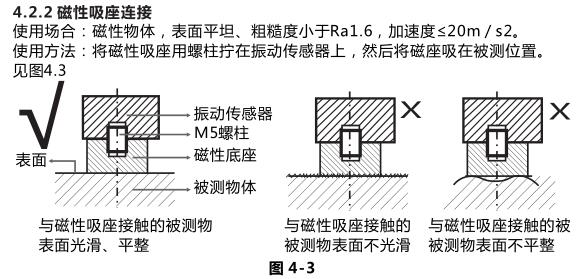

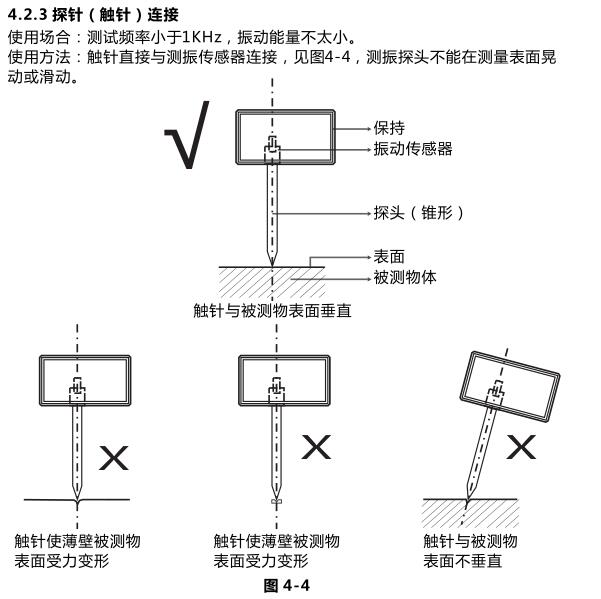

4.2 Performance comparison of installation methods

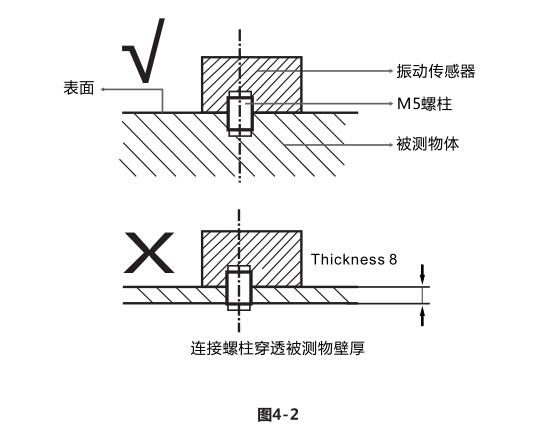

4.2.1 Stud connection

Application occasion: The threaded hole drilled on the surface of the measured object does not affect the operating performance of the measured object.

How to use: Drill M5 screw holes with a depth of 5mm on the surface of the measured object, and directly fix the vibration measuring probe on the surface with studs.

See Figure 4-2 on the measured object, which is a good use method for frequency response

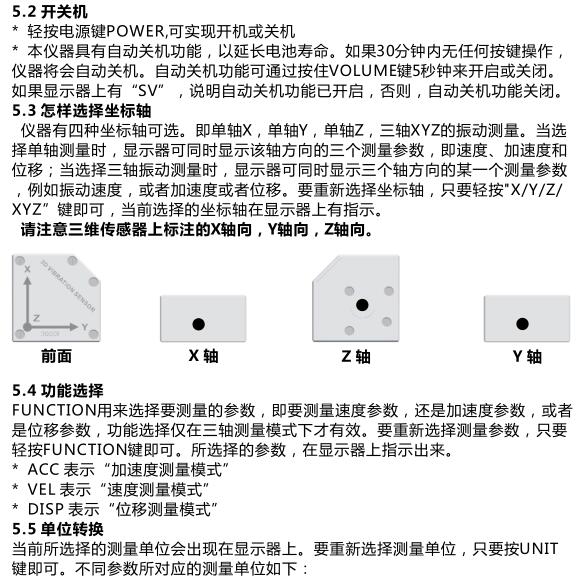

6. Selection and measurement overview of vibration parameters

6.1 When performing vibration measurement, which parameter should be measured?

Acceleration, velocity and displacement are three commonly used parameters that give accurate and repeatable results, other measured parameters have not been proven to be reliable and accurate. However, for some occasions, speed measurement and frequency measurement are also very important. Acceleration measurement has excellent high-frequency measurement performance. Therefore, it is very effective in judging the failure of bearings and gearboxes .

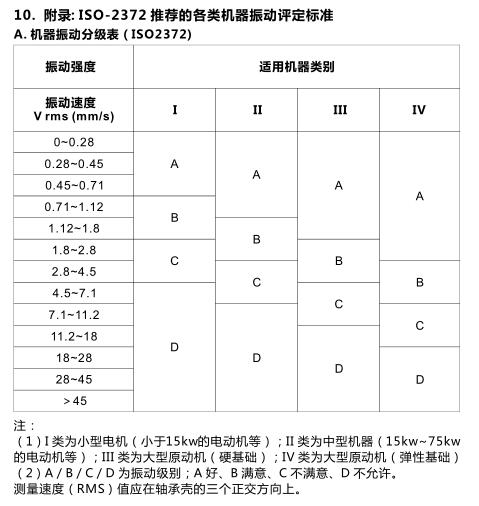

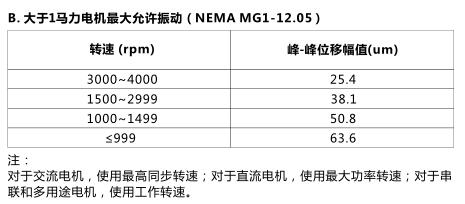

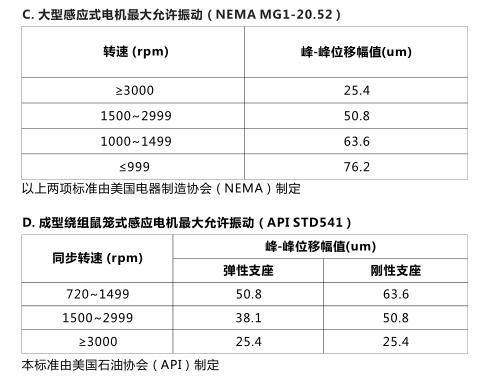

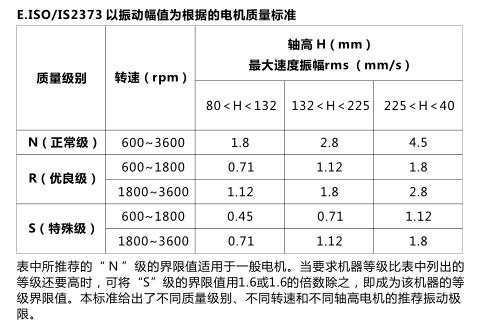

Velocity measurements are commonly used parameters in vibration analysis. For different power categories of machinery, when judging whether the mechanical vibration is acceptable, according to ISO2372, BS4678 or VD2056, speed will be the guideline for judging. The categories of machinery are listed in the appendix to this manual. Displacement measurement is mostly used for low-speed running machinery, which is characterized by good low-frequency characteristics, but when the bearing is installed, the displacement measurement effect is not satisfactory.

6.2 Overview of vibration measurement

振动测量是判断机械良好或某一特定设备运转是否正常的可靠尺度。一个称心的机械设备,若几乎没有振动,说明电机以及周边设备如齿轮箱、电风扇、压缩机等比较平衡、无偏离,安装良好。在实际中,很大比例的安装远不够称心。未对正、失衡的安装直接给支撑件如轴承等增加额外的张力,最终导致关键部件的磨损,造成效率低、发热,甚至瘫痪。当机械设备磨损和恶化时,设备的振动会增大,因此振动测量在设备的预先维护和减少停工方面具有极为重要的意义。

监测机械设备的振动,在它成为重大问题前,就检测出它的恶化,以便必要时提前订购备件和维修。通过一段时期的连续监测,绘出趋势图,将这些有价值的数据添加到设备的历史记录中。

6.3 什么是趋势图

趋势图就是被监测的振动参数随时间变化的一种表示方法。对于有规律的振动,画出振动参数在一定时间内的变化,就会表示出某一设备的发展情况或恶化情况。典型地,设备在安装后,无论是新的或修理过的,当设备运行时都会稍微变差,稍后将在一段正常的寿命期内,保持不变。当部件磨损时,振动加剧。这种趋势有助于帮助维修工程师提前预测故障时间,尽可能地利用该设备,同时订购备件和制订维修计划,以利生产。

7. 更换电池

7.1 当电池电压约5V时,显示器上将出现电池符号,需要更换电池。

7.2 打开电池盖,取出电池。

7.3 依照电池盒上标签所示,正确地装上电池。

7.4 如果在很长一段时间内不使用该仪表,请将电池取出,以防电池腐烂而损坏仪表。

8. 测量注意事项

8.1 The connecting cable of the sensor is easy to cause noise, and the cable winding and large shaking should be avoided. Another source of noise is poor contact of connectors, which should also be paid attention to.

8.2 The instrument should not be used in the environment of strong electromagnetic field interference or corrosive gas, and should avoid strong vibration and shock.

8.3 The sensitivity of the instrument is adjusted at the factory according to the sensitivity of the equipped sensor, so do not exchange the sensor .

8.4 Each measurement should be carried out when the machine is in the same operating state. Changing the operating state may change the vibration amount, thus drawing incorrect conclusions.

9. Vibration measurement points

9.1 Select the appropriate location and direction of the measuring point. Usually the measuring point should be on the rigid (not weak) structure , such as the bearing housing, and measure in three directions: horizontal, vertical and axial.

9.2 The part of the measuring point should be flat and clean, so that the magnetic suction seat of the sensor and the measuring point have a good plane contact, so that better frequency response characteristics can be obtained .

9.3 Each measurement shall be made in the same position and direction. For this purpose, marks should be made at the measuring points.

9.4 Measure the vibration of the machine at regular time intervals (such as daily or weekly), and make data records, so that correct diagnosis can be made by analyzing vibration changes and development trends.