1. Instrument overview

The concrete rebound Tester uses a spring to drive the hammer and the restoring force of the instantaneous elastic deformation generated by the bullet rod hitting the concrete surface, so that the hammer drives the pointer to bounce back and indicates the distance of the bounce. The rebound value ( the ratio of the rebound distance to the distance from the bounce hammer to the bounce rod before impact, calculated as a percentage) is used as one of the indicators related to the compressive strength to estimate the compressive strength of concrete. It is an instrument for non-destructive testing of the compressive strength of concrete in structures or components. Because the hammer is light, flexible, cheap, does not need power supply, and is easy to master , it is very suitable for use on site construction sites. In addition, the formulation and implementation of the corresponding testing procedures for the hammer and the technical regulations for testing the compressive strength of concrete with the rebound method ensure that It has improved its detection accuracy and has been .

The standard energy of the AL-150N rebound hammer produced by our factory is 2.207J. Its technical performance and main parameters are in line with the provisions of the national metrological verification regulations "Concrete rebound hammer" (JJG817-2011).

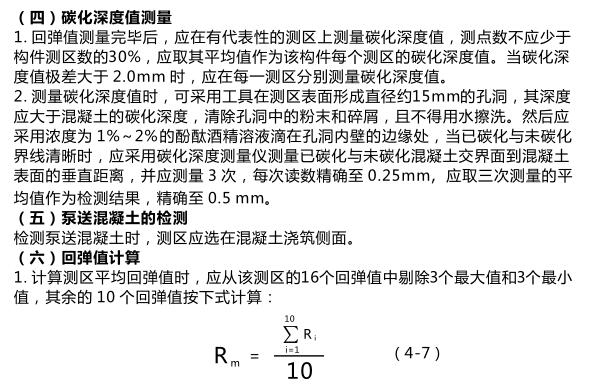

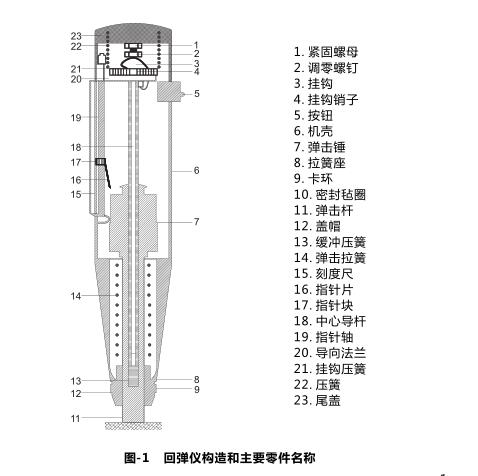

2. Instrument structure

Figure-1 shows the schematic diagram of the longitudinal section structure of the AL-150N rebound hammer after the impact and the names of the main parts.

3. Operation, maintenance and calibration of rebound hammer

1. Operation

1.1 Put the bullet dry against the surface of the concrete, press the instrument lightly to release the button, when the pressure is relaxed, the bullet dry sticks out , and the hook hangs the bullet hammer.

1.2 Make the axis of the instrument always perpendicular to the surface of the concrete and apply pressure slowly and evenly. After the bullet hammer is unhooked and impacts the bullet hammer , when the rebound of the bullet hammer drives the pointer to move backward to a certain position, the indication value on the pointer block The scale shows a certain value on the scale, which is the rebound value.

1.3 Keep the instrument movement against the concrete surface to take readings and record the rebound value. If the conditions are not conducive to reading , you can press the button to lock the movement and move the instrument to another place for reading.

1.4 Gradually depressurize the instrument, so that the ejection rod protrudes from the instrument, and wait for the next use.

2. Maintenance

Routine maintenance should be carried out when the rebound hammer has one of the following conditions:

2.1 More than 2000 strikes.

2.2 When there is doubt about the test value.

2.3 The steel anvil rate fixed value is unqualified.

Routine maintenance methods should meet the following requirements:

2.1 Take out the movement after unhooking the hammer, and then remove the hammer (take out the buffer spring inside) and the triple parts (hammer, spring and seat).

2.2 Use gasoline to clean all parts of the movement, especially the inner hole and impact surface of the center guide rod, ejection hammer and ejection rod . After cleaning, apply a thin layer of clock oil on the center guide rod, and other parts must not be oiled.

2.4 Clean the inner wall of the casing, remove the scale, and check the friction force of the pointer, which should be 0.5~0.8N.

2.4 Do not rotate the fixed zero adjustment screw on the tail cap.

2.5 No self-made or replacement parts are allowed.

2.6 Calibration test should be carried out as required after maintenance, and the calibration value should be 80±2.

3. Verification

When the rebound hammer has one of the following conditions, it should be sent to the statutory department for verification, and the verified rebound hammer has a verification certificate:

3.1 Before the new hammer is used.

3.2 Exceeded the validity period of the test (the validity period is half a year).

3.3 After routine maintenance, the fixed value of steel anvil rate is unqualified.

3.4 Suffer severe impact or other damage.

3.5 The rebound test should be carried out at room temperature (5°C-35°C), and the surface of the steel anvil should be dry, clean and firmly placed on a rigid object. The rebound value should take the average value of the stable rebound value of three consecutive downward bounces . Calibration should be carried out in four directions, the bullet dry should be rotated 90 degrees each time, and the average value of the three calibrations measured for each should be 80±2.

3.6 The steel anvil of the calibration hammer should be sent to the authorized metrological verification institution for verification or calibration every 2 years.

4. Operation, maintenance and calibration of rebound hammer

1. General provisions:

Concrete strength testing should have the following information:

1.1 Project name, design unit, construction unit.

1.2 Component name, quantity and concrete type, strength grade.

1.3 Cement stability; admixtures, types of admixtures; concrete mix ratio, etc.

1.4 Construction formwork, concrete pouring, curing conditions and pouring date, etc.

1.5 Necessary design drawings and construction records.

1.6 Reason for detection.

1.7 Before and after the test of the rebound hammer, the calibration test should be done on the steel anvil.

2. Detection

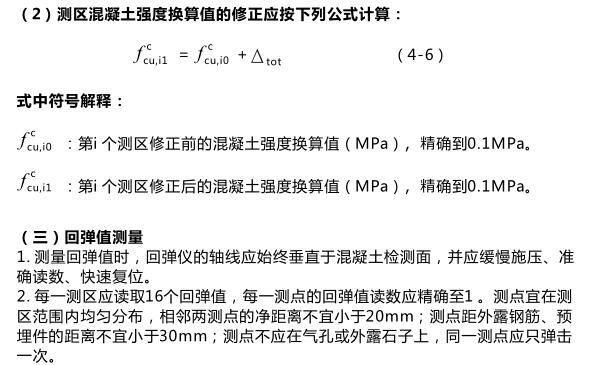

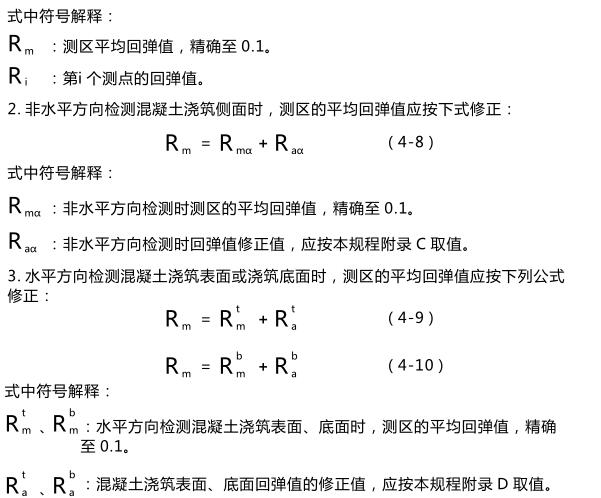

混凝土强度可按单个构件检测或按批量进行检测并应符合下列规定:单个构件的检测应符合(1~7)的规定:

2.1 对于一般构件,测区数不宜少于 10个。当检验受检构件数量大于 30个且不需提供单个构件推定强度或一方向尺寸不大于4.5m且另一方向尺寸不大于0.3m的构件时,每个构件的测区数量可适当减少,但不应少于 5个。

2.2 相邻两测区的间距不应大于 2m,测区离构件端部或施工缝边缘的距离不宜大于 0.5m,且不宜小于 0.2m。

2.3 测区宜选在使回弹仪处于水平方向检测,检测面宜为混凝土的浇筑侧面。当不能满足这一要求时,也可选在使回弹仪处于非水平方向检测混凝土的浇筑表面或底面。

2.4 测区宜布置在构件的两个对称的可测面上,当不能布置在对称的可测面上时,也可布置在一个可测面上,且应均匀分布。在构件的重要部位及薄弱部位应布置测区,并应避开预埋件。

2.5 测区的面积不宜大于 0.04m2。

2.6 测区表面应为混凝土原浆面,并应清洁、平整,不应有疏松层、浮浆、油垢、涂层以及蜂窝、麻面。

2.7 对弹击时产生颤动的薄壁、小型构件应进行固定。

2.8 按批量进行检测应符合下列规定:对于混凝土生产工艺、强度等级相同,原材料、配合比、养护条件基本一致且龄期相近的一批同类构件的检测应采用批量检测。按批量进行检测时,应随机抽取构件,抽检数量不宜少于同批构件总数的30%且不宜少于10件。当检验批构件数量大于30个时,抽样构件数量可适当调整,但不得少于有关标准规定的最小抽样数量。

2.9 The survey area should be marked with a clear number, and it is advisable to draw a schematic diagram of the survey area layout and describe the appearance quality .

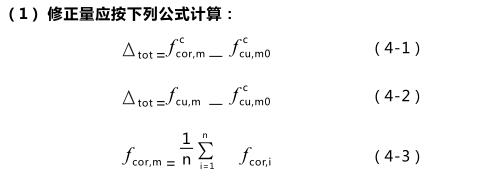

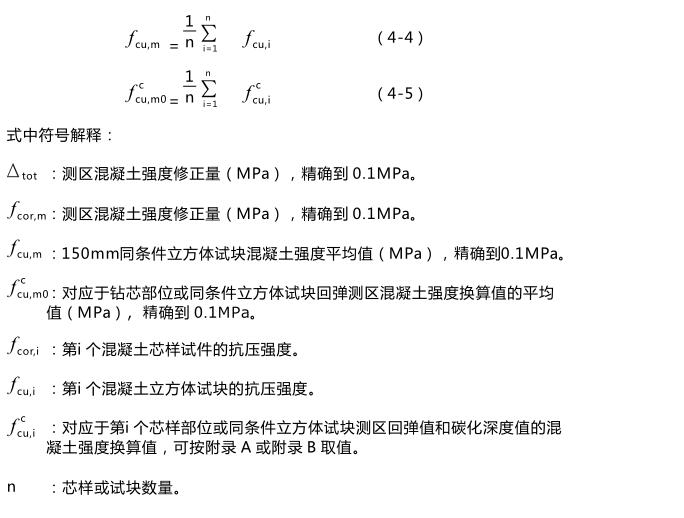

2.10 When there is a large difference between the test conditions and the applicable conditions of the unified strength test curve, the concrete core sample drilled correct the concrete strength conversion value in the test area. When correcting concrete of the same strength grade , the number of core samples should not be less than 6, the nominal diameter should be 100mm, and the ratio of height to diameter should be 1. Core samples should be drilled in the measurement area, and each core sample should only process one test piece. When correcting test blocks with the same conditions, the number of test blocks should not be less than 6, and the side length of the test blocks should be 150mm. When calculating, the correction of the concrete strength correction amount in the survey area and the conversion value of the concrete strength in the survey area shall meet the following requirements: