Integrated statistical type; can store 99 sets of new measurement data values. It has the characteristics of small measurement error, high reliability, good stability, and easy operation. It is an indispensable non-destructive testing instrument for controlling and ensuring product quality.

1. Product description

This instrument is a battery-powered portable measuring instrument that uses the principles of magnetic induction and electric temperature flow. The measurement method complies with international standards IS02178, IS02360 and national standards Gb4956, Gb4957. It uses computer technology, non-destructive testing technology and other professional technologies to accurately measure the thickness of the measured object without damaging it.

*F-type probe can directly measure the thickness of the non-magnetic covering layer on the surface of the magnetic conductive material (such as iron, ring) (such as: paint, plastic, porcelain, copper, aluminum, zinc, network, etc.). It can be used to measure the thickness of electroplating layer, paint layer, bearing layer, aluminum tile, copper tile, babbitt alloy tile, phosphating layer, paper, and also can be used for thickness measurement of hull paint and attachments of underwater structural parts.

★Nf-type probe can measure the thickness of the insulating covering layer on the non-magnetic metal substrate, such as paint, plastic, rubber coating on the surface of aluminum, copper, zinc, non-magnetic stainless copper and other materials, and can also measure aluminum or aluminum alloy materials thickness of the anodized layer.

*The spring-drawing guide sleeve probe with wear-resistant hard metal probe can not only measure on hard or rough surfaces, but also ensure that the probe has constant pressing force and stable sampling value.

* Wide measurement range and high resolution.

★Automatic memory calibration value, easy to use.

* Integrated structure, small size and light weight.

★Digital backlight display, no parallax.

*99 sets of data can be stored; the statistical function of the instrument can be realized by measuring the average value, maximum value and minimum value.

*Using the optional RS232C software and cable, it can communicate with PC computer to realize the functions of data collection, processing, analysis and printing.

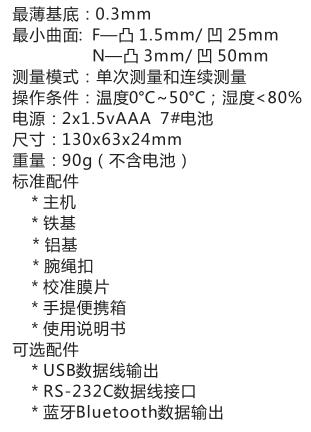

* This instrument is equipped with automatic shutdown to realize power saving function. 2. Technical specifications

Display: 4-digit backlit LCD

Standard test range: 0~1250um

(Other measurement ranges can be customized)

Resolution: 0.1um (below 100um)

1um (below 100um)

Measurement accuracy: ±1~3%n or ±2.5um

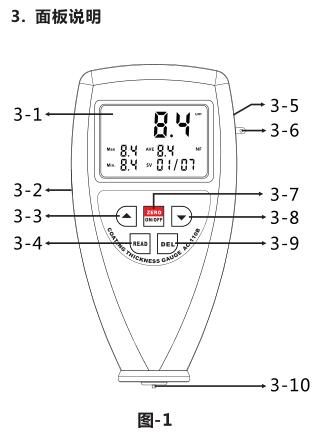

4. Measurement procedure

4.1 Press the power button lightly, and after turning on the power of the whole machine, the instrument will automatically enter the measurement state, and automatically restore the parameter settings before the last shutdown.

4.2在确认校准正确的前提下,就可开始测量。若对以前的校准有所怀疑的话,应再进行一次校准。校准的具体方法洋见仪器的校准部分。仪器一旦校准,校准结果将自动存贮在仪器中,下次开机测量时,可不必再次进行校准,除非对测量的准确性有怀疑。

4.3将测量传感器压紧到被测涂层上,显示器上的値即为待测涂层的测量值。如有必要,测量値可通过加一键或減一键来修正。需要注意的是,按加一键或減一键修正时,测量探头一定提起,否则按加一键或减一键无效。

(注意:由于所有的磁性涂层测厚仪都是采用电磁感应原理;非磁性涂层测厚仪采用电潟流的原理,因此一定要注意探头压上被测体的速度不能太慢。否则,会造成人为测量误差。)

4.4要进行下一步测量,需要将测量传感器提起到一厘米以上,然后再重复上述步骤。此仪器可自动存储每一次的测量値同时,测量时的最大值、最小値、平均値和测量次数都呈现在屏幕上。

4.5若要更换测量单位,只要轻按电源键不放,直到显示器上出现"UNIT"松手即可。(从按下电源键到出现UNIT大约需要6秒钟)

4.6若要更换测量模式,实现単次测量和连续测量的转換,也可以通过轻按电源键不放,直到显示器上出现SC才松开按键即可(从按下电源键到出现SC大约需要8秒钟)。在开机未测量时,若显示器上没有符号”C(·i)显示(仅测量时显示),表示单次测量模式,每测量一次,蜂口9器都响一下。若Ct·)1”一直显示时则表示连续测量模式,测量时,蜂口9器不响。

5.数据统计

5.1此仪器可自动完成数据的统计与分析功能,具体包括:

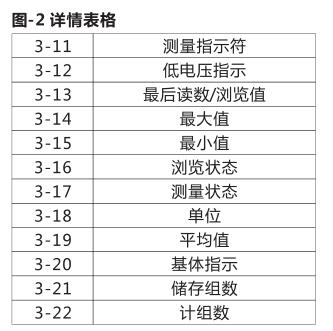

A.测量的平均値。(符号“AVE"表示)

B.测量时的最大值和最小値。

("Max"表示最大値,"Min"表示最小値)

C.测量次数和统计个数

5.2当测量基体"F"和"NF"转換或重新开机时,所有显示器上的数据将According to新一轮的数据来重新统计。

5.3当存储的数据超过99组时,则最后测量的数值自动存储后,较早的测量値将自动册⊠除,依此类推。

6.数据的储存与查看

测量的每一组数据都会自动保存到仪器里如要査看之前记最时,只要轻按"READ"键然后松手,当显示器上出现"RD〃符号时说明机子处于浏览状态;这时按·▼"或▲"键来浏览存储在主机里的数据。(注意:当显示器上出现”SV"时表示测量状态,不能对之前的测量数据进行査看)

7.删除数据

对数据的删除分为两种:单次册ll除和一次性清除A.测量状态时,即显示器上显示"SV·时,轻按"DEL·键再松手,最后一个值将被删除,同时测量次数也跟着递減;浏览状态下,按动”▲·或"▼·键,调出存储在机子里的数据,再按·DEL·键将数据逐个删除。当屏幕上显示”Err0·时,则表示存储的数据已经清除完毕。

B当要删除系统里的所有数据时,只要按住"DEL·键不松手持续4-5秒钟,显示器所有数据则显示为·0"。(此操作只有在SV”测量状态下才可以操作。)

8.电脑连接

8.1依照电池盒上标签所示,利用可选的

USB数据线输出"、"RS232C数据线输出"和"蓝牙BluetoothTM数据输出",可与PC计算机通讯,实现数据的采集、处理、分析和打印等功能。具体操作请见8.3按动“READ"将存储数値依次传送到计算机中,用户可According to实际需要导出所需文格式。

8.4联机测量时,具体参见软件光盘中的Demo.exe。

9.仪器校准

9.1校零

将测量探头压在基准块上(或不带涂层的测量体上),再轻按一下校零键·POWER"进行校零。在按nPOWER”键时,测量探头在基准块上不要晃动,同时要注意,只有在按完·POWER"键后,才能提起探头,否则,校零不正确。可重复操作以求得更准确校准。

9.2校准满度

9.2.1According to要测量的涂层厚度,选择适当的标准膜片,进行满度校准。

9.2.2先将标准膜片放在基准块上(或不带涂层的测量基体上)。

9.2.3再将测量探头压在标准膜片上,测量值就显示在显示器上,若测量値与标准膜片不同,测量値可通过加一键或减一键来修正。

9.2.4为保证校满度的准确性,可通过多次测量同一标准膜片来验证。

10.电池更換

10.1当池电压约2.5V时,显示器上将电出现电池符号,需要更换电池。

10.2打开电池盖,取出电池。

10.3依照电池盒上标签所示,正确地装上电池。

10.4如果在很长一段时间内不使用该仪表,请将电池取出,以防电池腐烂而损坏仪表。

11.注意事项

11.1为了減少测量体材质对测量精度的影口向,建议采用不带涂层的测量体或与测量体材质相同的标准试块作为校准用基准块。

11.2测量完毕轻按一下电源键,关断整机电源。若较长一段日i间不用,建议在测量头的触头及基准块上涂少许油脂以防生锈。

11.3仪器应防止剧烈振动、撞击。使用后应擦,争仪器表面油污放入仪器箱内妥善保存。

11.4严禁敲击或碰撞探头以免影响探头性能。

A.测量状态时,即显示器上显示"SV·时,轻按"DEL·键再松手,最后一个值将被删除,同时测量次数也跟着递減;浏览状态下,按动”▲·或"▼·键,调出存储在机子里的数据,再按·DEL·键将数据逐个删除。当屏幕上显示”Err0·时,则表示存储的数据已经清除完毕。

B当要册lll除系统里的所有数据时,只要按住"DEL·键不松手持续4-5秒钟,显示器所有数据则显示为·0"。(此操作只有在SV”测量状态下才可以操作。)

8.电脑连接

8.1依照电池盒上标签所示,利用可选的

"USB data line output", "RS232C data line output" and "BluetoothTM data output", can communicate with PC computer to realize the functions of data collection, processing, analysis and printing. Please refer to 8.3 for details. The stored data is transmitted to the computer in turn, and the user can export the required file format according to actual needs.