There are many types of electric heating furnaces that can be seen at present, such as high-temperature box-type electric heating furnaces, tubular electric heating furnaces, rotary tubular electric heating furnaces, increasing end electric heating furnaces, Oil Bath electric heating furnaces, and intermediate frequency coreless induction melting furnaces. , Powder metallurgy sintering electric furnace, etc. Box-type electric heating furnaces, tube-type electric heating furnaces, and Electric Heating Plates are commonly used in chemical laboratories.

1. Box type electric heating furnace

The shape is cuboid, the furnace shell is welded with thin steel rice, and the furnace is made of refractory material. The outer layer of the hearth is opened with a back pocket, and the pocket is embedded with a helical coil of nickel wire. The space between the hearth and the kiln is made of diatomaceous earth and expanded perlite as the insulation layer.

The furnace door is fixed on the surface of the electric furnace through supports and keys, and a heat shield is placed at the furnace mouth inside the furnace door. There is a temperature measuring hole on the shield surface of the furnace, and a thermocouple is installed. The lower part of the furnace is equipped with an electric device to control the furnace temperature, and there is also an electronic automatic temperature control device to control the furnace temperature.

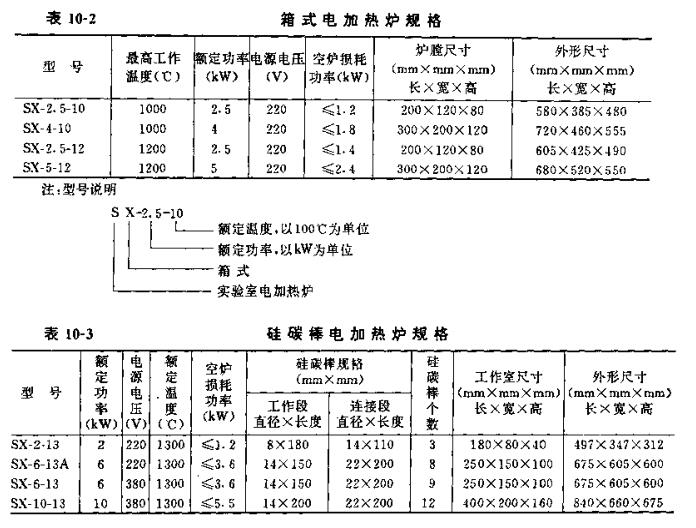

Table 10-2 lists several specifications of SX series box-type electric heating furnaces commonly used in laboratories.

If a higher burning temperature is required in the laboratory, a high-temperature electric furnace with a silicon carbide rod as a heating element can be used, and the working temperature can reach 1300 °C. The outer casing is a square body welded with steel plates, and the hearth is made of high alumina stone to form a rectangular shape. When light clay is used between the outer casing and the furnace wall, silicon carbide rods are installed on both sides and top of the furnace. The furnace temperature is adjusted with an autotransformer.

Select four specifications of domestic silicon carbide rod high-temperature electric heating furnaces listed in Table 10-3

2. Tube electric heating furnace

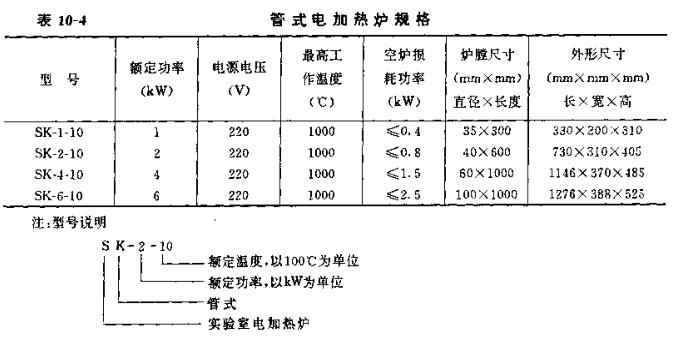

In the chemical laboratory, the tubular electric heating furnace is mainly used for chemical analysis, physical property determination, thermoelectric stiffness correction, and catalytic reaction research.

The temperature of the tubular electric heating furnace with molybdenum-chromium alloy wire as the heating element can reach 950°C, the temperature of the tubular electric heating furnace with silicon carbon tube as the heating element can reach 1300°C, and the tubular electric heating furnace with silicon pin as the heating element The temperature can be as high as 1600°C.

The shape of the tubular electric heating furnace is a horizontal cylinder; the base is made of thin steel rice; the furnace shell is made of thin steel ring; the furnace is a tubular body made of refractory material, and there is a spiral groove outside to place the heating wire , The furnace and the outer shell are filled with insulation materials such as perlite and refractory fiber; the furnace temperature is controlled by a silicon controlled silicon temperature controller.

Table 10_4 lists the main specifications of the SK series tubular electric heating furnace with alloy wire as the heating element.

3. Heating plate

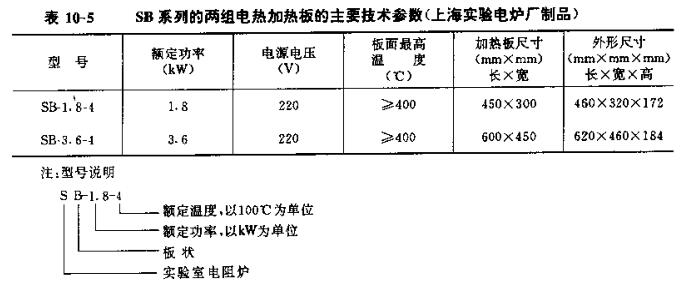

The Electric Heating Plate has the characteristics of convenience, uniform heat dissipation, safety and cleaning, etc. It is mainly used in the laboratory for quantitative analysis of boiling solutions, evaporation, etc., because the heating surface of the Electric Heating Plate is large, suitable for heating many beakers, evaporating dishes, conical flasks at the same time etc. (see Figure 10-1).

The structure of the Electric Heating Plate: the heating panel is made of smooth special iron plate; the housing is welded by thin steel plate; the heating element is made of iron-chromium-aluminum electric heating alloy strips wound into two groups and installed in parallel in the housing, the bottom of the alloy strip and the surrounding Filled with refractory fiber; the temperature is automatically controlled by a thermal expansion thermometer and a relay.