Viscosity cups can quickly and easily measure the viscosity of varnish and other Newtonian fluids (approximate Newtonian fluids). Different products may use different Viscosity Cups according to different standards, but the principle is roughly the same: that is, under certain temperature conditions, quantitative The time (in seconds) for the sample to completely flow out of a hole of specified diameter.

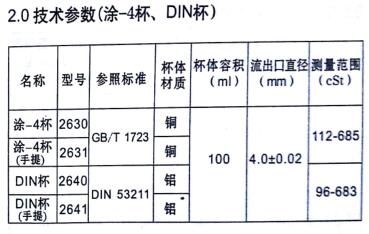

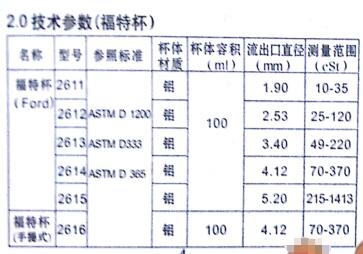

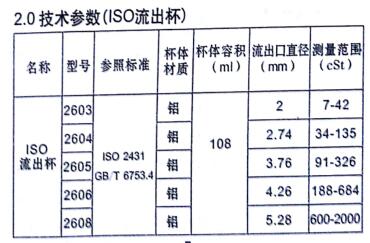

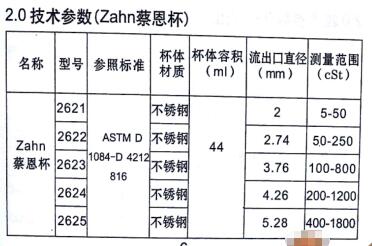

Viscosity cups are basically divided into two types: desktop and portable. The desktop precision cup usually needs a horizontal support, while the portable one is used for multiple quick measurements. The content of this manual is suitable for the operation and use of national standard Tu-4 cups, Ford cups, DIN cups, Zion cups and 1S0 outFlow Cups.

3.0 operation

3.1 Before use, use a suitable solvent to wipe the inner wall of the cup clean (note: please pay special attention to cleaning the small hole of the cup body, twist it into a rope with soft paper; pull it repeatedly in the outflow hole, and then dry it in j medium or use cold air Blow dry, not allowed on the cup body and spout.

3.2 Choose an appropriate cup number to control the outflow time between 20_80 seconds (see technical parameters).

3.3 Stir the test solution evenly, filter it through a sieve with no less than 567 holes/cm2, and control the temperature of the sample crystal and the cup at (20±0.5°C) or another agreed temperature.

3.4 Adjust the horizontal bolts of the cross platform to center the horizontal bubble (this step can be omitted for portable Viscosity Cups), and the horizontal bubble may also be located on the Viscosity Cup bracket.

3.5 Inject the strong sample into the Viscosity Cup, and block the outflow hole with one finger at the same time (if it is a corrosive liquid, wear corrosion-resistant rubber gloves)

3.6 After filling, use a metal or glass flat plate to scrape the cup flat, scrape the excess sample into the groove on the edge of the Viscosity Cup, and adjust the position of the cup.

3.7 Take your fingers away and press the stopwatch at the same time.

3.8 When a breakpoint occurs, stop timing, and the outflow time at this time is the viscosity value of the test sample.

Note: For the portable Viscosity Cup: pick up the handle of the portable Viscosity Cup, fully immerse the cup body in the sample, and then quickly and smoothly lift the cup body vertically from the sample to be tested. When the upper end of the cup is separated from the liquid surface, the cup must be kept vertical when the liquid flows out, and the distance from the liquid should not exceed 150mm.

3.9 Repeat the measurement three times, and the average value is the final reading.

3.10 Immediately clean the cup with a suitable solvent. Never use metal cleaning tools or wire. If the residue in the outflow hole dries and hardens, it should be softened with an appropriate solvent first, and then carefully cleaned, for example, scrubbing with a soft cloth through the outflow hole.

4. 0 maintenance precautions

Due to the drop and collision of the Viscosity Cup, the outlet port will be deformed, resulting in errors in measurement, so care must be taken during use. Please place it in a dry and clean environment when not in use.

5.0 calibration

5.1 Viscosity cups should be calibrated regularly after each year of use (the diameter of the outflow nozzle before leaving the factory should be calibrated in the factory with tallow oil that can be traced back to NLST oil, and the user does not need to calibrate after one year of purchase)

Process calibration requires standard silicone oil according to the relevant national Viscosity Cup measurement regulations.

6.0 conversion

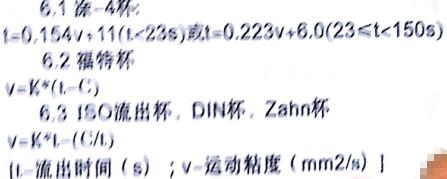

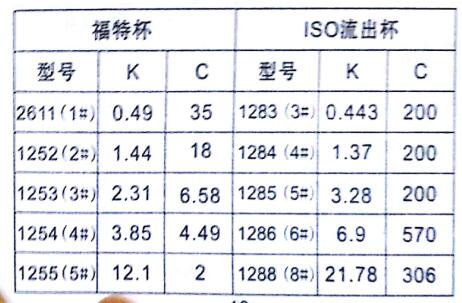

For a particular dipping cup the results are to be expressed in "seconds" at a specified temperature, or to convert "seconds" to centistokes, see the following formula: