Use and maintenance of Air Compressor

Before starting up, a sufficient amount of lubricating oil should be injected into the crankcase (observe the oil mark line), check the smoothness of the suction transition and the discharge port, and check whether the safety valve is rusted. Turn the pulley by hand to check whether there is any obstacle when turning, whether the connecting parts are loose, and finally turn on the power.

During the normal operation of the Air Compressor, the temperature of the cylinder head should not be higher than 150°C, and the temperature of the air storage tank should be lower than 50°C. Every 24 hours or so of work, the sewage discharge under the gas storage tank should be opened to discharge the condensed water.

Always pay attention to whether the sound of each part is abnormal. The abnormal sound in the cylinder may be the damage of the piston; the abnormal sound of the intake and exhaust valve may be the damage of the valve plate or spring; or bearing wear.

Clean the suction filter frequently. Pay attention to supplementing lubricating oil, use No. 13 compressor oil in winter, and use No. 19 compactor oil in summer.

Generally, it runs for about 2500 hours, and the cylinder, intake valve, exhaust valve, and piston should be cleaned.

Other types of compressors

In recent years, oil-free gas compressors have been increasingly used in chemical laboratories. Because the discharged gas is oil-free, it is very suitable as a gas source for modern instruments and used in fields such as medicine and environmental science.

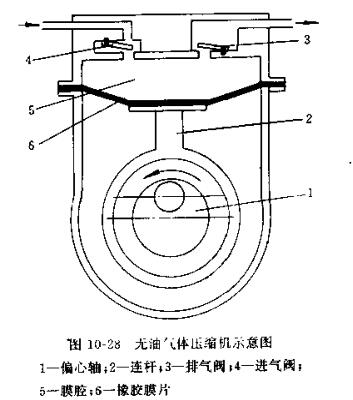

Its working process is: the eccentric shaft is driven by the motor to rotate, and the connecting rod drives the special rubber diaphragm to reciprocate up and down once every revolution, completing a gas compression cycle (see Figure 10-28). When the eccentric shaft rotates downward and the rod and the diaphragm move downward, the intake valve of the membrane cavity opens, the air at normal pressure enters the membrane cavity through the filter, and the exhaust valve is in a closed state. When the eccentric shaft rotates upwards, the connecting rod and the diaphragm move upwards, the intake valve closes, the exhaust valve opens, and the gas in the membrane cavity is pressed out.

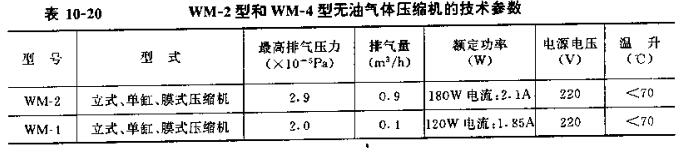

Table 10_20 lists the technical parameters of two types of oil-free gas compressors (products of Tianjin No. 2 Medical Device Factory).

Use and maintenance:

(1) A 4A fuse should be connected in series with the power cord of the motor as a short-circuit protection for the motor, and the casing should be grounded;

(2) All pipelines and components are strictly prohibited from overpressure work to avoid accidents;

(3) The air intake filter should be cleaned frequently (clean the ash with soapy water after removal, rinse it with water and alcohol, and dry it), so as to ensure the normal operation of the intake and exhaust valves;

(4) The whole machine needs to be overhauled and cleaned once every 1000 hours of use.