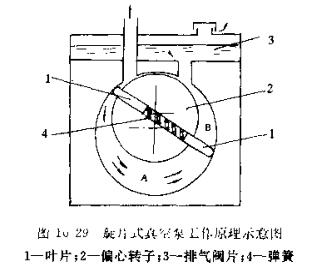

Working principle and structure

As shown in Figure 10-29, an eccentric rotor contains two blades with a spring in the center, which rotate in the stator, so that the volume in the stator expands and contracts periodically, so as to achieve the purpose of air intake and exhaust. As shown in the figure, the eccentric rotor is equipped with a rotor 2 rotating in the direction of the arrow, and a blade 1 is installed in the groove of the rotor. When the rotor rotates, the blade slides along the inner surface of the working chamber under the action of the spring 4. The volume of the space A surrounded by the chamber wall, rotor blades and end benefits increases, and the gas in the pumped container is sucked in through the intake pipe. At the same time, when the rotor rotates, the volume of the space B shrinks, so that the gas in it is compressed, and the ridges are flushed out for exhaust. In this way, the two vanes that work in turn can ensure that the pump is continuously inhaled and exhausted to achieve the required vacuum.

Use and Maintenance

Add Vacuum Pump oil according to the scale indicated on the oil mark before use.

Turn the belt pulley by hand to check the running condition. After there is no abnormality, turn on the power (pay attention to the direction of rotation).

When the pump is stopped, in order to maintain a certain degree of vacuum in the vacuum system, a check valve should be installed on the intake pipe to prevent the pump oil from flowing backwards, or a three-way valve should be installed to close the vacuum system and the suction port of the pump should communicate with the atmosphere. .

Vacuum pumps should not be used to pump out gases that contain too much oxygen, are explosive, and are corrosive to metals. In addition, it is not recommended to inhale gas that can react with pump oil or gas containing a large amount of water vapor.

After using for a period of time, the belt becomes loose, and the position of the motor needs to be adjusted. Pay attention to replenish the pump oil, and if you find sundries or water in the pump oil, replace it with new oil and clean the pump body (do not use volatile liquids such as ethyl acetate and acrylic acid for cleaning).