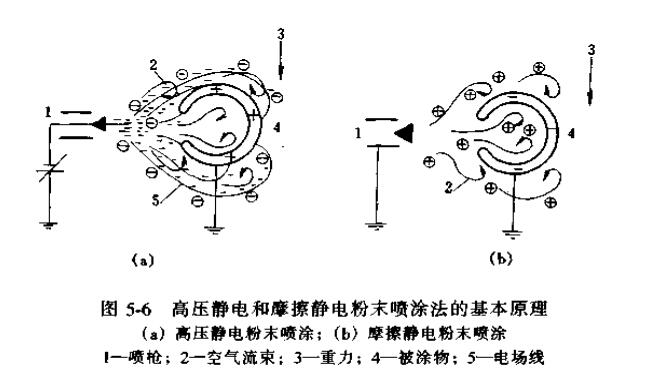

The electrostatic powder coating method is a coating method that uses the high-voltage electric field induction effect to induce the powder coating and the coated object to be charged with opposite charges, thereby attracting the powder coating to the coated object. It is the most widely used method at present. The small mobile electrostatic powder spraying equipment is that when the powder coating passes through the high-voltage electrostatic Spray Gun or friction electrostatic Spray Gun, the powder coating is charged with static electricity and is attracted to the coated object with the opposite charge. , and then put the object to be coated in a furnace-like bake to level it into pieces. Thermoplastic powder coatings only need to be melted and leveled; while thermosetting powder coatings need to be cross-linked and cured to form a film after melting and leveling. In the electrostatic powder spraying method, there are two types: the new piezoelectric powder spraying method and the frictional electrostatic powder spraying method. The basic principles of these two spraying methods are shown in Figure 5-6. It can be seen from the figure that in the high-voltage electrostatic spraying method, when the powder coating passes through the electric discharge needle, it is negatively charged, and due to electrostatic adsorption, it falls on the positively charged object. However, due to the Faraday shielding effect, the powder coating cannot In the friction electrostatic spraying method, the powder removal material is positively charged when it passes through the friction electrostatic Spray Gun, and is attached to the negatively charged coating by sub-electrostatic adsorption and the powder coating can be to the recessed surface of the object to be coated. The differences and characteristics of high-voltage electrostatic and tribostatic Spray Guns will be introduced in detail in the chapter "Powder Spraying Equipment".

There are two processes for electrostatic powder coating. If the required coating thickness is less than 150µm, the object to be coated can be sprayed directly with electrostatic powder after the surface has been cleaned. This spraying method is called cold spraying method; When the film thickness is required to be more than 150µm to hundreds of microns, after the surface treatment of the coated object, it must be preheated before electrostatic powder spraying. This spraying method is called thermal spraying method. The particle size distribution of the powder coating for electrostatic powder spraying is required to be 20~100µm; the voltage is 30~90kv,

The electrostatic powder cold spray method has the following advantages:

①The object to be coated does not need to be preheated, and can be sprayed directly after surface treatment;

②Suitable for coating film with a thickness of 50~150μm;

Easy to understand, easy to control the thickness of the coating film, and easy to realize automatic spraying method;

④ The thickness of the coating film is uniform, and it is not easy to flow;

⑤ Strong adaptability to various powder coatings, most powder coatings can use this spraying method (but the frictional electrostatic spraying method is optional);

⑥The flexibility of the coated object can be sprayed with different sizes and shapes of the coated object, including the inner and outer walls of the pipeline;

⑦The overflowing powder method material can be recycled and reused, and the utilization rate of the paint is high.

The electrostatic powder cold spraying method has the following disadvantages;

① It is only suitable for coating films with a thickness of 50~150µm, not suitable for spraying coating films with a thickness of 150lµm or more;

②It requires a large investment in equipment to remove and recycle the spilled powder; if there are many types of coatings and colors, the investment in equipment is even greater;

The electrostatic powder thermal spraying method has the following advantages:

①The coating film thickness of one spraying can reach more than 150, which is suitable for thick spraying;

② For castings with sand holes, the coating film of cold spraying will have disadvantages such as counting holes, but the hot spraying method can overcome the formation of pinholes;

③Most powder coating varieties can use this high-level coating method, which is adaptable to various powder coatings; although;

④ It has strong responsiveness to the object to be coated, and can spray off objects of different sizes and shapes, including the inner and outer walls of the pipe;

⑤ In addition to the film thickness, the durability and anti-corrosion performance of the coating film are good, and some varieties can also be machined after spraying.

The electrostatic powder thermal spray method has the following disadvantages:

① The uniformity of the coating film thickness is not easy to control, and it is easy to flow when the film is too thick;

②Because the object to be coated needs to be preheated, the powder removal is affected by heat during the spraying method, so it is difficult to recycle the sprayed paint of some paint varieties.

From the above situation, the cold spray method and the thermal spray method have their own advantages and disadvantages, but the cold spray method seems to be more superior. The user should choose the coating process according to the installation object, the requirements for the original coating, etc.