(1) Equipment

The structural principle of the instrument for the anti-cutting test device is shown in Figure l0_7.

Piano wire: 1mm in diameter.

Oven: The highest temperature can reach: 300°C, the heating rate is 50-60°C/h, and the error of the temperature measuring device should not be greater than ±5°C.

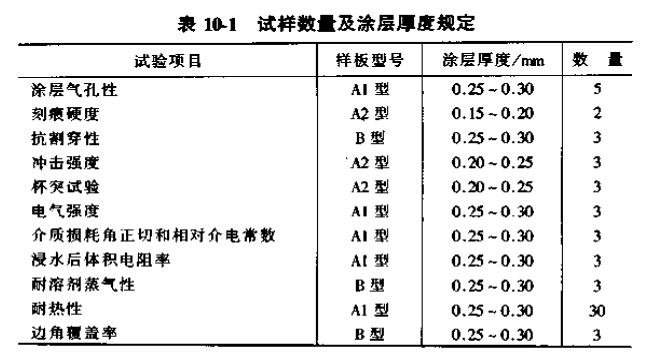

(2) See Table 10-1 for samples.

(3) Test procedure

The sample central tight on the instrument, the sample protrudes about 100mm. Put the piano wire on the sample, and the two ends of the wire are fastened to the iron form. The basic weight of the iron form is 0.5kg, the total load can be 5N, 10N, 20N, 50N or 100N, and the load value applied in the test is selected according to the requirements.

Apply a 100v DC voltage between the piano wire and the base to connect it to the signal device.

Place the instrument with the sample loaded in a circulating ventilated oven, start from 30~40°C and heat up at a rate of 50~60°C/h. The temperature measurement point should be as close as possible to the cut-through point of the coating. When the signal device indicates that the coating is damaged, the indicated temperature value should be recorded immediately.

(4) Results

Take the middle value of the temperature values measured by the three samples as the cut-through strength under the specified load, indicated by the load value and temperature (°C).