Heat resistance (GB6554-86)

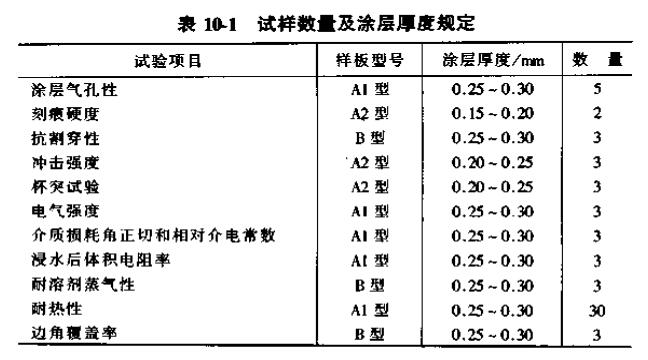

Evaluate according to "Guidelines for Determining Heat Resistance of Electrical Insulation Materials, Part 1: Establishing General Procedures for Thermal Aging Test Methods and Evaluation Test Results of Insulating Materials", see Table 10_1 for samples. With 3000v, AC 50Hz, 1min withstand voltage breakdown as the end of life, the electrodes specified in "Electric Strength" are used, and the medium is air.

Thermal shock resistance (GB 6554-86)

(1) Equipment

Circulating ventilation oven.

Dry ice plus acetone or ethanol bath: There should be enough heat capacity to keep the temperature of the sample after immersion.

(2) Sample

There are 3 samples, the substrate is purple collar, the shape and size are shown in Figure 10-10.

(3) Test procedure

Put the 3 samples in a general box which has been stabilized to the required temperature for half an hour, then take them out and quickly put them in a bath essence at 30°C and 2°C for 10 minutes.

After each cycle, dry the sample and check whether the layer is cracked or detached. When the sample cracks and detaches, it is regarded as the sample has been damaged.

Repeat the cycle test until the sample is damaged, or repeat the test according to the specified number of cycles to check whether the sample is damaged.

(4) Results

Report the sample coating damage, the number of cycles or the damage of the sample when tested according to the specified test cycle.