Paint film bending test (cylindrical axis) (GB/T6742-86) This standard is to evaluate the cracking resistance of paint and varnish coatings (including single-layer and multi-layer systems) when they are bent around a cylindrical axis under standard conditions or from metal Test method for the performance of the base plate.

Paint film bending test (cylindrical axis) (GB/T6742-86) This standard is to evaluate the cracking resistance of paint and varnish coatings (including single-layer and multi-layer systems) when they are bent around a cylindrical axis under standard conditions or from metal Test method for the performance of the base plate.

This standard is mostly based on the international standard lS0 1519--1973 "Paints and varnishes - Bending test (cylindrical shaft)".

(1) Instrument

① Bending Tester: This instrument is suitable for samples with a thickness not greater than 0.3mm.

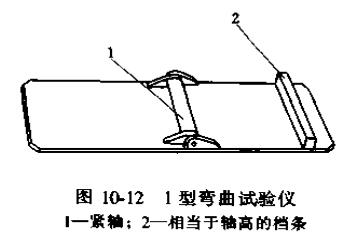

②Shaft diameter: the instrument is shown in Figure 10-12 and Figure 10-13. The input diameters are 2mm, 3mm, 4mm, 5mm, 6mm, 8mm, l0mm, 12mm, l6mm, 20mm, 25mm and 32mm.

(2) Operation steps

① Unless otherwise specified, the test is to be carried out at a temperature of 23°C±2°C and a relative humidity of 50%±5%.

②Open the instrument completely, insert the template, and make the painted film face the seat plate, and then it can be bent. The operation should be within 1 to 2 seconds, and the instrument should be closed smoothly rather than suddenly, so that the sample is rotated 180° on the axis. The whole process is carried out under the test conditions specified in this standard, and the temperature of the sample caused by incorrect operation should be avoided. high.

②Open the instrument completely, insert the template, and make the painted film face the seat plate, and then it can be bent. The operation should be within 1 to 2 seconds, and the instrument should be closed smoothly rather than suddenly, so that the sample is rotated 180° on the axis. The whole process is carried out under the test conditions specified in this standard, and the temperature of the sample caused by incorrect operation should be avoided. high.

③ After bending, check the sample immediately without taking it out of the instrument. Use normal eyesight or a 10 times magnifying glass to check whether the coating is cracked or separated from the bottom plate according to the product standard requirements (excluding the coating with a height of less than 10mm on the edge of the plate). If a magnifying glass is used, it should be indicated in the test report. Results obtained with normal vision are misleading.

④ Test the shafts with smaller diameters on the sample board in turn (from the largest to the smallest diameter shaft) until the coating film cracks or peels off from the bottom plate. Repeat the operation with the same shaft diameter on a new sample plate. After proving the result, record the shaft diameter that preferentially causes the coating film to crack or detach. If the smallest diameter of the pump does not damage the coating, record that the method does not damage the film when it is bent on the smallest diameter shaft.