The cross-cut test of paint and varnish film (GB/T9236-88) This standard is equivalent to the international standard IS02409-1972 "Paint and varnish - cross-cut test".

This International Standard specifies empirical test methods for evaluating the coating properties of paints, varnishes and related products. This is one of the performance measurement methods that can be used among the factors related to the adhesion of the coating to the substrate. However, this method should not be regarded as a method of measuring adhesion itself.

(1) Main content and scope of application

This standard specifies a simple empirical test procedure for evaluating the resistance of coatings of paints, varnishes and related products to detachment from the substrate when the coating is cut in a grid pattern and penetrates just enough to the substrate .

(2) Instrument

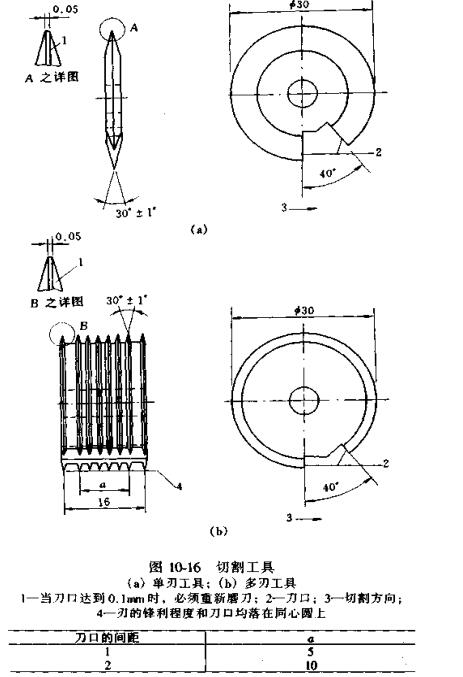

① The cutting tool can use a single-knife mechanical cutting load or a single-knife or multi-knife manual cutting tool, or other suitable equipment. No matter which one is used, it should be able to draw a cutting with high uniformity.

②The standard cutting edge angle of the cutting edge is 30°, and the cutting edge thickness is 50~100μm, for example, 80μm. Single-edge and multi-edge tools shown in Figure 10-16 are one of the applicable tools of this standard.

③ soft brush.

④Test plate: thin steel plate, tinplate plate, aluminum plate or glass plate that shall meet the requirements of GB/T9271.

(3) Test procedure

①Unless otherwise specified, the test should be carried out in an environment with a temperature of 23°C±2°C and a relative humidity of 50%±5%.

② Number of cuts: The number of cuts l1 in each direction of the grid pattern should be 6 or 11, which should be agreed upon by the relevant parties

③ Cutting spacing: The cutting spacing in each direction should be 1mm or 2mm at the same time. The choice of spacing. It should be agreed upon by the relevant parties according to the nature of the coating

④ Cutting method: Install the qualified cutting tool and adjust the balance of the cutting arm. Then add a weight of appropriate quality on the upper part of the tool so that the edge of the knife can just penetrate the coating and touch the substrate during cutting. Use a soft brush to gently reciprocate 5 times along the two diagonal directions of the grid.

⑤ Test repeatability: The test shall be completed at least at 3 different positions of the test plate. If the test results of the 3 positions are judged to be inconsistent by the following grading method, the test shall be repeated at the other 3 positions, and all the results shall be recorded at the same time.

(4) Evaluation

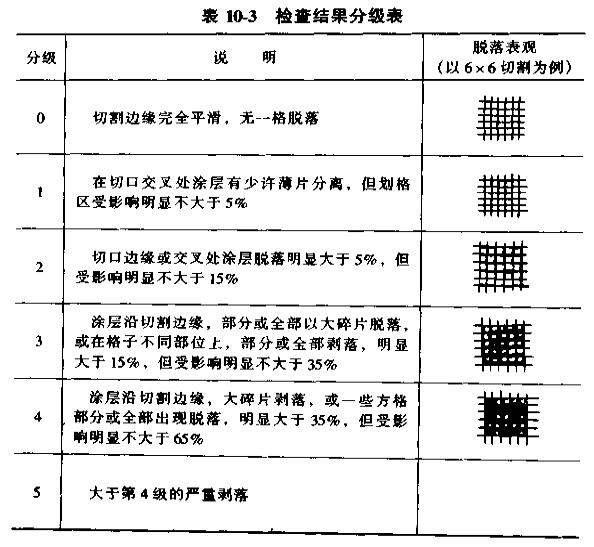

① Table 10-3 gives the classification by 6-level evaluation, the first 3 levels usually meet the general purpose, and use "pass" or "fail" to evaluate. In special cases, it needs to be evaluated according to 6-level classification.

② Inspection: Check the cut surface of the test spread with normal vision (or normal vision after correction), compare it with the description in the table below and the drawing, and grade according to the comparison result.

If it is necessary to use a magnifying glass in special circumstances, the use of the magnifying glass, especially the magnification, shall be agreed upon by all parties involved.