Coating film hardness pencil test method (GB/16739-86) This standard uses a known hardness pencil to measure the hardness of organic coating film, which is suitable for the development research and industrial production control of coatings.

For maximum accuracy in the ratio, use a set of High School brand premium drawing pencils from the same batch.

The operation can be done by manual method or instrument test method, but the instrument test method should be used as an arbitration subtraction test.

(1) Materials and instruments

① A set of Zhonghua brand high-end drawing pencils 6H, 5H, 4H, 3H, 2H, H, HB, B, 2B, 3B, 4B, 5B, 6B, among which 6H is the hardest, 6B is the softest, and the hardness decreases from 6H to 6B .

② Pencil sharpener.

③ Pencil scratch Hardness Tester for film removal.

④ No. 400 sandpaper.

(2) Determination steps and conditions

①Use a pencil sharpener to sharpen the pencil to expose the cylindrical core of 5~6mm (do not loosen or scratch the lead), hold the pencil so that it is at 90° to the surface of No. 400 sandpaper, and keep drawing a circle on the sandpaper. Rub the end face of the lead core until the end face is flat and the edge is like a sharp pen end (the edge must not be broken or notched). The boat pen should be rotated 180° after each use, or re-sharpened before use.

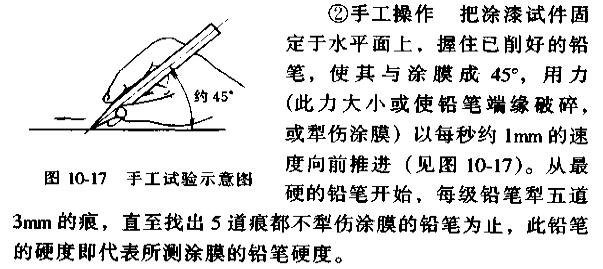

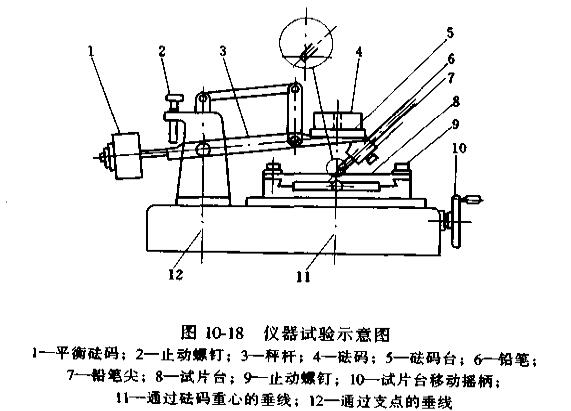

③Instrument test Put the painted piece on the test piece table of the Tester, with the painted surface facing up, adjust the vertical line passing through the center of gravity of the magnetic code of the Tester to the intersection point between the tip of the pen and the painted surface, and place the sharpened pencil Put it into the pencil holder so that it forms an angle of 45° with the painted surface. Adjust the load on the boat pen with a flat breaker to make the pencil just touch the test piece, hold the stop ring nail tightly, and make the pencil end leave the painted surface. Add a magnetic code of 1kg±0.05kg to the weight table, and loosen the stop screw so that the pencil end is in contact with the painting. Shake the moving rocker arm of the test platform, so that the test piece and the pen end of the pin move 3mm in the opposite direction, and the moving speed is about 0.5mm/s.

Then tighten the stop screw, turn the wrong pen 180° (to ensure that the end face of the pen is not damaged) and change the position of the test piece, and plow out 5 marks in sequence (see Figure 10-18). Use this method to start the test from the hardest pencil, and replace it with lower-level pencils one after another until you find 5 marks, only one of which plows the film, and the next-level wrong pen represents the measured smear gland. The hardness of the boat pen. If the coating film is not damaged by plowing, use the drill pen of this level to represent the hardness of the coating film to be tested.

Carry out according to the conditions stipulated in product standards or construction requirements, and the arbitration test shall be carried out under the standard conditions of temperature 23°C±2°C and relative humidity 50%±5%.