1. Fully meet the gas consumption needs of gas equipment

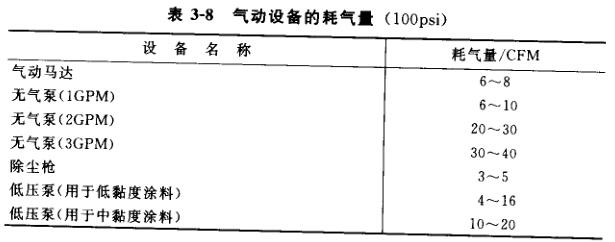

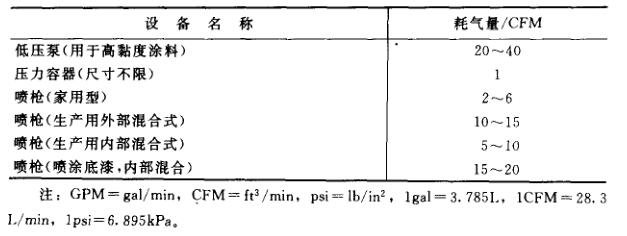

Calculate the highest air consumption according to the type and quantity of pneumatic equipment, and take into account the possible increase in air consumption in the future, and then select the Air Compressor equipment that can meet the air supply requirements of the pneumatic equipment. The air supply capacity of the compressor should exceed the demand (at least a 25% margin). When calculating the output of the compressor, the actual gas production of the compressor should prevail, and the theoretical calculation of the gas production should not only be considered. Under the pressure of 689.5kPa, the actual gas production can be deduced from the empirical formula, that is, the electric motor per horsepower (1 Horsepower = 0.746kW) the gas production is 0.13m3/min, and the gas production per horsepower of the air motor is 0.057m3/min. At the same time, the decrease in actual gas production due to the increase in altitude and the increase in ambient temperature is considered. A lot of moisture and high humidity in the air will also reduce the gas production capacity of the compressor. The air consumption of various pneumatic equipment is shown in Table 3-8.

2. The maximum pressure required by pneumatic equipment

After knowing the maximum pressure required by the pneumatic equipment, you can determine the use of single-acting, double-acting or multi-acting Air Compressors.

3. Choose according to construction requirements

Diaphragm compressors can be selected for small household construction, and reciprocating Air Compressors are often used for general construction. It is better to prepare two Air Compressors, one with high power for full-time work at full load, and the small one for half-day or partial load, so that the air consumption requirements of the system can be met in different situations. There is a backup compressor on standby, even if the other compressor fails, it will not affect the work. The two compressors are regularly rotated on a weekly basis, which is conducive to keeping both compressors in good working condition.

4. Select the control method according to the construction characteristics

If the gas is used continuously and stably, an Air Compressor with a constant speed control device should be selected; if the gas is used intermittently, an Air Compressor with an automatic shoulder/close control device should be selected. If the gas is used intermittently and sometimes continuously during construction, it is necessary to use an Air Compressor with a dual control device (both an automatic open/close control device and a constant speed control device).