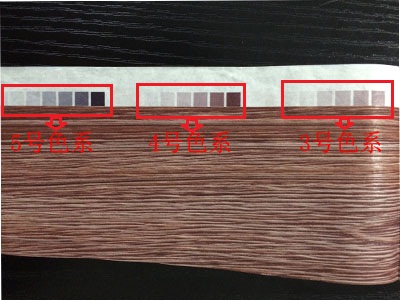

Decorative paper is a kind of decorative base paper printed with wood grain, stone grain, bamboo grain and other patterns (as shown in Figure 1), then impregnated with melamine, and hot-pressed with wear-resistant paper onto high- and medium-density MDF boards. On paper, it is made into floor, furniture, etc., which plays a role of decoration and protection. The color difference of decorative paper is mainly in the printing process, due to the large number of colors (generally 3-4 color overprinting), the different patterns of each color, and the influence of many factors such as people, machines, materials, methods, environments, and measurements in the production process, Color difference control is difficult and there are many customer complaints. Therefore, color difference control is a topic that many decorative paper printing companies are eagerly discussing.

Figure 1 Decorative paper

The purpose of decorative color difference control is to ensure the consistency of pattern color within each batch of products or between batches. So how to control the color difference of textured decorative paper or other textured objects? Color spectrum Spectrophotometer to help you!

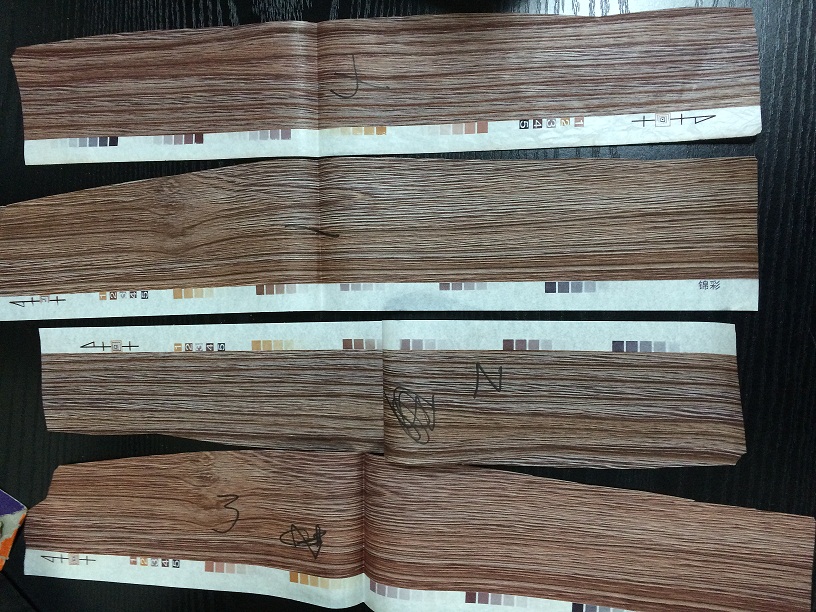

Since the decorative paper has textures, there will be several small color blocks on each decorative paper during production, and marked with serial numbers, each color represents a color system, and these 5 color systems are contained in the texture (as shown in the figure two).

Figure 2 Small color blocks of decorative paper

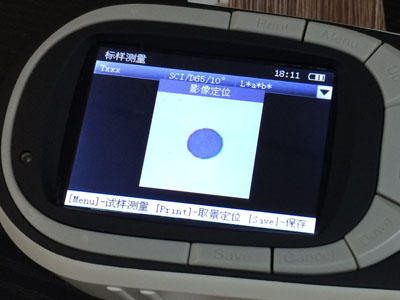

Therefore, as long as the Spectrophotometer is used to measure the color in the small color block and then compared with the sample provided by the customer, it can be measured very well. We selected the first small color block of No. 1 color system for measurement. And because the area of the color block is small, we choose the Spectrophotometer CS-600B with a caliber of 4mm for measurement. Compared with ordinary Colorimeters, CS-600B has higher stability and precision, and the built-in camera measures more accurately.

Figure 3 Spectrophotometer

The specific method is as follows: After the black and white calibration is completed, turn on the viewfinder function of the Spectrophotometer camera and measure the first small square of the No. 1 color system in the sample 1 to be tested, as shown in the figure below.

sample

camera viewfinder

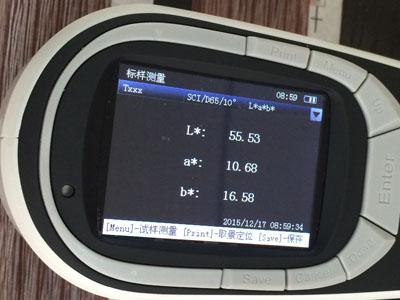

measured data

Then measure the first small color block of No. 1 color from the 4 samples, and then measure the color difference between the samples. The measured L, A, B data are as follows:

Table 1 L, A, B data of the same color block of 4 samples

| sample | L | A | B |

| 1 | 54.82 | 11.61 | 16.83 |

| 2 | 55.53 | 10.68 | 16.58 |

| 3 | 49.95 | 15.51 | 9.41 |

| 4 | 49.92 | 15.33 | 9.70 |

During production, it can be compared with the sample provided by the customer, so as to control the color difference and achieve the result that satisfies the customer. Many customers are worried that samples with texture are difficult to measure, so why not try this method?